The rear air suspension of the Prado 120 is quite common. Unlike the classic spring design, rubber cylinders filled with air are installed here. A system capable of changing hardness was also installed on the Toyota Land Cruiser 100, but its operation was ensured by a special fluid. In the Prado, this function is performed by compressed air .

The advantage of this suspension is that the ground clearance does not depend on how loaded the Prado 120 is.

The position of the body is closely monitored by two sensors, thanks to which the pneumatics maintain the required height. The adjustment occurs automatically; in addition, the driver has the opportunity to choose one of the three available operating modes . This allows you to increase off-road capabilities or improve handling on asphalt at the right time.

Prado 120 air suspension control

General arrangement of the rear axle air suspension.

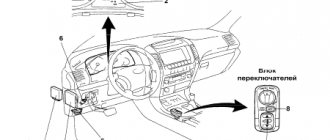

The Prado 120 air suspension is controlled using a switch block . There is an “OFF” key on it, which turns off the automatic mode, and a knob that allows you to select one of the manual control options: high (HI), medium (Normal) and low (LO).

In HI mode, the ground clearance increases by 30-40 mm (the amount depends on the modification). This takes 15-20 seconds. In low LO mode, the Prado body squats by 30 mm in 10-15 seconds.

Air suspension switch block

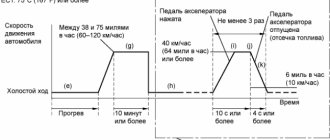

When automatic control is activated and the flag is turned to Normal mode , at speeds over 50 km/h the suspension will be in the middle position. If you drive slower, the ground clearance will increase as much as possible. When driving less than 12 km/h, the ground clearance will drop to a minimum, and vice versa.

Front suspension repair

After removing the protection, you should carefully unscrew the racks using a hexagon. Open the stabilization link. Change pads, discs, calipers. On average, wear per 100 thousand kilometers is 1.5 mm. If the anti-squeak plate is worn out, install a new one. When replacing lower control arms, oxidation of the bolts is often detected. In this case, you need to carefully cut them off.

Option for changing the tie rod: tear off the cotter pin in strips on both sides. Unscrew the nut. Unscrew the upper lever, carefully removing the battery. If there is wear on the bolt, replace it. The new one should not be tightened. Unscrew the thrust bearing on the lower ball bearing. Remove the lever by first removing the nut.

Retract the attached steering rod. Remove the shock absorber. Unscrew and clean the cup. Spray with rust preventative. Insert new adjustable shock absorbers and spring. When installing the same shock absorber strut, if the bolts that connect it and the hub bearing housing are tightened, then there is no need to adjust the wheel angles.

Nuances of operation and adjustment of pneuma

, body roll to one side is often discussed . The reason for this is not a breakdown, but the inexperience of drivers and their laziness to study the operating instructions. Some owners go to a car service center with this problem; they are very lucky if they come across an honest mechanic who will explain everything and will not force them to pay for the “repair”.

We are talking about the roll of the car after parking on an uneven surface. To prevent this from happening, you need to turn off the automatic switching mode of the Prado 120 air suspension before parking on uneven surfaces or when jacking up the car.

If this is not done, then during subsequent parking the body will warp. This happens because at the moment the engine starts, the control system reads the position of the suspension at the moment and remembers it , taking it as horizontal.

If the situation is skewed, adjusting the air suspension of the Prado 120 will correct it.

- Place the Prado 120 on a flat surface.

- By pressing the “OFF” key, turn off automatic mode switching.

- Turn off the engine.

- Start the engine again and press “OFF” to activate the automatic mode selection system.

Operation of the Prado 120 air suspension off-road

When towing the Prado 120 , turn off the automatic suspension mode and set it to the “Normal” position. When driving off-road, turn off automatic mode selection and move the switch to the “HI” position.

The manufacturer prohibits the use of the pneumatic control system in frosts below -30°. When operating in such weather conditions, it is necessary to turn off the automation and set the body to the middle position.

Frequent problems with Prado air suspension: reviews from owners

In reviews, owners of Prado 150 SUVs with air suspension often write that air springs (airbags) can explode. Malfunctions of the compressor responsible for lifting the car are also common. And when operating the car at a temperature of -30, it is recommended to completely disable the automatic air suspension mode on the TLK Prado 150. As during repair work, if it is necessary to jack up the car or before parking on an uneven surface. If you do not turn it off, this may cause the SUV to roll when stopping, and the car will skew.

Maksim. I encountered problems during frosts at Pradika. Once I had to travel 550 km there and then back at a temperature of -35, and sometimes at -43. As I got closer to the house, I began to feel that the car was getting harder and harder, and at the end of the journey it felt like I was driving on a stool. In the end, it turned out that the SUV fell on the bump stops; the pneuma categorically refused to work. I drove into a warm place, Pradik warmed up, turned on the air, everything seemed to work, but at night I still had to leave the car on the street. The next day, at first everything more or less functioned, although the compressor took too long to pump air. The car spent the night in the cold again and eventually fell again. As it turned out, there was a problem with one of the cylinders; due to low temperatures, the rubber of the cylinder hardened and cracked, so the air came out of the system. I didn’t notice this visually; it became clear only after careful analysis at the service station.

Vitaly. My Prado J150's height sensors rotted due to reagents. Depending on the area where the car is operated, the compressor, fittings or sensors may simply rot due to reagents. It is advisable to periodically check the air pressure, even if there is no need.

Diagnostics

To avoid unpleasant surprises on the road, it is necessary to regularly diagnose the Prado 120 air suspension . For self-diagnosis, there is a connector in the interior of the SUV. And the technical instructions for the Prado 120 describe this process in detail.

Prado120 technical documentation and instructions can be found here.

Technical instructions Prado 120

It is useful to visit a car service center from time to time to check the air suspension of the Prado 120. The following signs :

- when the engine is not running, the car sags;

- one of the selected manual modes is not held;

- the valves in the electromagnetic block are not sealed;

- after starting the engine, the front or rear of the car rises.

First, computer diagnostics . Check the serviceability of the system, valves and sensors. Then the mechanic checks the pneuma for external defects and eliminates them.

Diagnostic connector

Monitor the condition of the air suspension. A fault detected in time will help you avoid unpleasant surprises on the road.

Checking the front suspension elements

A classic front suspension check includes analysis of 4 elements:

- Lower arm. Check and restore/replace the tightness of nuts and bolts. Examine the part for cracks and deformation.

- Racks. It is recommended to press each of the body corners one by one, releasing them sharply. The rack is in good condition if the body returns to its original position without swaying. A little moisture is acceptable, but it is important not to let the liquid leak. Examine the condition of the upper bushing. Even slight play indicates the need for replacement.

- Coil spring. There are no defects when the position of the car relative to the road surface is normal. If skewed, the spring needs to be replaced.

- Longitudinal thrust. You can replace or restore damage and wear of rubber bushings, the reliability of tightened nuts and bolts.

Every element of the test is important. You need to act according to a strict scheme, step by step.

Prado 120 air suspension design

The air suspension control system (ANS) consists of the following mechanisms.

- ABS control unit for Prado without pneuma.

- Door position limit switches.

- Speed sensors.

- ANS system relay .

- Pneumatic cylinder.

- A sensor that determines the amount of ground clearance.

- Air valve Prado 120.

- Control valve.

- Bypass valve.

- Release valve.

- Air filter.

- Trunk opening sensor.

Air suspension control system (ANS)

pneumatic indicators and switches on the dashboard:

- ANS system mode indicator .

- Pneumatic on/off indicator.

- ANS control unit .

- TEMS control unit .

- Connector for diagnostics.

- Stop signal switch limit switch.

- Flag for switching pneumatic modes.

- Air switch " OFF ".

Pneumatic indicators and switches

The Prado 120 air suspension system also includes the following mechanisms :

- block that controls electrical equipment (receives information from limit switches and redirects it to the AHC );

- ABS control unit (sends information from speed sensors to the ANS );

- ANS system control unit .

Compressor

The Prado 120 air suspension compressor consists of an air dryer, an exhaust valve and the compressor itself . Let's look at the purpose of each of these parts.

Compressor device

The compressor supplies air to the air cylinders that lift the body. It only works when the engine is running. The name of the exhaust valve speaks for itself - air comes out through it when the body is lowered. There is always some amount of water vapor in the air. A dehumidifier is used to remove condensate from the system.

Receiver

The receiver is composed of a valve block and an additional air tank . The air released by the pneumatic cylinder temporarily accumulates in an additional container. This reduces the time spent changing the suspension height.

Receiver device

The Prado 120 air suspension valve block consists of three elements:

- bypass valve - serves to bypass air between pneumatic cylinders;

- control valve – connects the compressor and the pneumatic cylinder;

- pressure relief valve – connects the pneumatic cylinder and additional capacity.

Body position sensors

These mechanisms are located on the Prado 120 air suspension and are responsible for determining the height of the body above the road.

The design of body position sensors

The body sensor of the Prado 120 is designed simply. The shaft is connected to a brush that runs over a resistor. The interaction of the resistor and the brush forms resistance; it has a variable value and depends on the angle at which the sensor shaft is rotated. When the brush is rotated, the output voltage also changes.

Pneumatic cylinder

A pneumatic cylinder maintains the body at a given height, raising or lowering it as necessary. The pneumatic cylinder ensures smooth operation. Structurally, this is a separate air chamber containing compressed air.

Pneumatic cylinder

Link to replacing the Prado 120 air spring.

Rear suspension troubleshooting

Auto mechanics note a simpler rear suspension design. But this does not mean less functionality. Variants of faulty elements: levers, racks, silent blocks. Troubleshooting steps:

- Full check of the condition of the rubberized shock absorber bushings. All faulty components are replaced.

- If the adjustment or hub bearings are broken, experts recommend adjusting the preload. Next, the defective bearings should be replaced.

- Bushing fit analysis. If loosening is noticed, tighten the fasteners with several measured movements.

- If one or more leaf springs are broken, replace the entire spring.

- If the axle housing is deformed, replace it.

- Diagnostics of the spring clamp and the strength of its fastening.

To understand whether the front axle is positioned correctly, you need to measure the distance from the reference point on the axle housing to a similar place on the chassis. Re-measure between equivalent points on the other side of the machine. Normally, when the situation does not require repair work, the results coincide by 90%.