During the operation of a car, a large number of different errors occur. Each of them has a certain meaning and carries a potential threat.

Some errors are rather warning and indicate the need to carry out some kind of repair and restoration work in the near future. However, further operation of the machine with such errors is permitted.

There is another category of errors, if identified, it is better to immediately carry out repairs and refrain from traveling.

You should find out what category the P0500 error belongs to, what it says, and what are the reasons for its occurrence. Plus how to fix the problem on your own.

What does the error mean?

The error in question is directly related to the vehicle speed sensor, or its electrical circuit.

Error P0500 indicates a sensor malfunction or a problem in the electrical circuit. In English it sounds like Vehicle Speed Sensor.

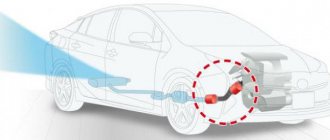

This type of malfunction is typical for vehicles equipped with an anti-lock braking system. It prevents skidding.

The operation of the ABS system is controlled by the ECU. The latter compares the speed at which the car's wheels rotate and the speed at which the crankshaft rotates. The control signal passes through the ECU. If the vehicle speed sensor produces incorrect data, this leads to the formation of error P0500, which is stored in the memory of the control unit.

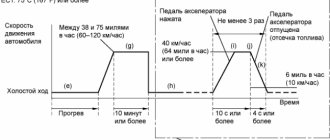

For such an error to be recorded, 5 conditions must be met at once.

Resetting error information to the ECU

After eliminating technical faults, you should not forget about resetting the error information in the ECU. One way is to remove the negative terminal from the battery for a few seconds, but this can only be used as a last resort. You can free up memory using a software error reset. In this case, a diagnostic tool and software are used.

To avoid problems with speed sensors, you should carefully monitor the condition of the contacts, the integrity of the wires themselves and their insulation. P0500 is “treated” by resoldering the contacts of the input sensor on the gearbox. It is necessary to ensure that the rotating ring of the mechanical drive of the sensor is seated correctly. You can work with the scanner yourself, so it’s a good idea to purchase it for personal use.

It should be noted that with the Check Engine light activated, you can continue to operate the car. But this is not advisable, since the driver will not be able to see other serious problems.

Formation conditions

In order for this error to be recorded and stored in the control unit’s memory, several conditions must be met.

- The angular speed of rotation of the internal combustion engine crankshaft exceeds 1600 rpm.

- At the time the error is detected, the temperature of the engine cooling fluid should be more than 80 degrees Celsius.

- Load parameters (TL) exceed 3 milliseconds.

- The ECU signal indicating the vehicle speed transmits a value of about 5 kilometers per hour. Although on others it may be 9 kilometers per hour or less.

- All of the above conditions appear together, and their duration ranges from 4 seconds or more.

Immediately after one cycle of these conditions, the Check Engine light comes on on vehicles with automatic transmission. If the car has a mechanic, then this will happen on the second trip or the second start from a standstill.

If these conditions are met, the ECU will record an error and store it in memory. As a result, corresponding symptoms will appear, forcing the motorist to pay attention to a potential malfunction in the system.

Diagnosis of error P0500

Symptoms of malfunction

There are several signs that may lead a motorist to believe that an error code with the value P0500 has been recorded in the memory of the electronic unit. The symptoms are rather indirect.

- The ABS system is disabled. The anti-lock braking system will automatically turn off because the control unit has detected a malfunction.

- The engine draft control system stops working. The reason is similar. Due to this error, the ECU disables this system.

- The lamp indicating the operation of the brakes on the instrument panel lights up.

- At the same time, the check engine light comes on. He is everyone’s unloved Check Engine.

- If your car has an automatic transmission, it may be difficult to change gears.

- The operation of the speedometer is disrupted and it may display incorrect information.

- If some programs are programmed into the ECU, a forced maximum speed limiting system is activated.

To confirm or refute the theory that the speed sensor is entirely to blame, you will need to perform diagnostics.

Symptoms of a Vehicle Speed Sensor error

Outward symptoms of a P0500 code include one or more of the following:

- The speedometer and/or odometer (if equipped) does not work fully or partially (incorrectly). This is especially true for electronic speedometers.

- Cars with automatic transmissions may shift incorrectly (incorrectly) because the ECU cannot make the correct decision about how fast the car is going.

- The ABS system and/or traction control system (TCS) may be disabled (the ECU forces them into limp mode).

- The ABS and/or brake warning lights on the instrument panel are activated.

- On some machines, the maximum speed and/or engine speed will be forced to be limited.

If at least one of the listed problems occurs, it is necessary to diagnose the ECU using appropriate software.

Causes

There are several possible causes for the error code represented as P0500. This depends on the specific make and model of the car. The reasons appear separately or several at a time.

- Faulty speed sensor. Sensor failure is not the most common occurrence, since it is a reliable and durable element. But this option cannot be excluded. It is important to consider that the sensors are installed on the drive wheels. Depending on the drive type, a corresponding number of controllers will need to be checked for integrity.

- Broken wiring or short circuit. These phenomena can occur in the electrical or signal circuit of the sensor.

- Loss of contact. Again, the contact may be broken in the signal or electrical circuit. Deterioration in the quality of contact occurs due to poor connection of the chip, oxidation, rust, etc.

In most cases, during the inspection it is possible to discover that the contact is broken or does not exist at all. Because of this, the diagnostic equipment reports a lack of signal from the speed sensor. This leads to the appearance of error P0500 and all the accompanying symptoms.

Methods for troubleshooting P0500

How to resolve error code P0500 Vehicle Speed Sensor depends on the reasons that caused it. The simplest method of elimination is to simply reset the error (software or simply by disconnecting the negative terminal of the battery) in the ECU. However, this method is suitable only in the mildest cases, for example, when the controller accidentally operates, its so-called “glitch”. However, in some cases, such a simple measure helps.

More serious actions involve searching for faults in the electrical (signal) circuit of one and/or another speed sensor, in the instrument panel, or in the computer. On some forums you can find the opinion that if error P0500 occurs, the ABS unit needs to be replaced. Actually this is not true. This is done only in extreme cases, when the designated part has actually failed.

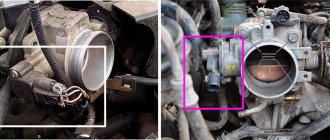

Most often, the cause of error P0500 (except for software) is poor contact or damaged insulation on individual wires. Therefore, you need to start with software diagnostics, and then use a multimeter to consistently “ring” the circuit. For this, in addition to the device, you will also need a diagram of the electrical component of the machine. You can find it in the documentation or on the Internet. It also makes sense to check the contacts directly on the sensor. On forums you can often find information from car owners that the error is caused by oxides on its contacts. Naturally, you need to get rid of them. Since the contact plates are small and set deep, a liquid is often used that removes oxidation, and then treated with a lubricant that conducts current and forms a protective layer.

This is interesting: What are the best means to blacken rubber yourself?

Although the P0500 error is not critical, the search for the reasons that caused it can be quite difficult and time-consuming. In the most difficult situations, it is necessary to disassemble individual parts of the interior, for example, wire channels above the thresholds of the car. So be prepared for this.

In rare cases, it is possible to replace the speed sensor (if it completely fails), although this does not happen often, since it is a fairly reliable and durable unit. In even more rare cases, the mechanical drive of the sensor, which has worn out, is replaced. This device itself is an electromagnetic sensor operating on the basis of a rotating relay ring. It is the rotating mechanism that can wear out over time.

In the case described above, when the ABS ring does not rotate synchronously with the CV joint, everything is “treated” quite simply. To do this, you need to use a core to put the ring in its seat or simply replace it if it has worn out significantly. The procedure is simple, but takes a lot of time.

On some Opel models, the diagnostic connector under the hood of the car is cut (even official representatives state that magnetic interference from other wires is possible). However, if you decide to do this, you need to know exactly which wire to cut! In other cases, on Opels (this is also true for other brands of cars), they simply clean the contacts (from dust and possible dirt). In even more rare cases, some car owners get rid of the 0500 error by resoldering the contacts (connector) of the input sensor (relevant for rear-wheel drive cars with a sensor installed on the gearbox).

After eliminating the technical malfunctions that led to the formation of error code P0500, do not forget to reset the information about it to the vehicle’s ECU. This can be done in two ways. The first is to remove the negative terminal from the battery for a few seconds. After the electrical contact is restored, the electronic control unit will reboot and again diagnose the machine, where there will no longer be an error. However, this method is unpopular and can only be used in cases of extreme necessity.

The second method is to software reset the error. To do this, you need to use a diagnostic tool and software with which the error was identified. Each program has a corresponding function that allows you to free the ECU memory from all information.

In general, it is worth noting that error P0500 is not critical, so when its code is generated in the ECU, the machine can be used. However, it is better to eliminate it, if only because the Check Engine light will be activated, and if more serious problems with the car are detected, the driver will not be able to find out about it.

Troubleshooting

When a P0500 code appears, it potentially points to several sources of problems. It could be:

- the speed sensor itself;

- dashboard electronics;

- ECU.

The speed sensor on front-wheel drive vehicles is usually located in the wheel bearing. If the drive is rear-wheel drive, the installation location will be a differential or gearbox.

Before you begin diagnostics and repairs, make sure that the problem is not with the speedometer itself. It's easy to do. You just need to do a test drive.

Speed sensor for car

If the diagnostic scanner shows a P0500 error, you need to do the following:

- Using diagnostic equipment, check the operation of the speed sensor. Not everyone has special equipment in their garage. Therefore, the easiest way is to connect a known-good controller. If the error does not go away after resetting, continue searching.

- Using a multimeter, check the circuit between the input signal and ground, or the power wire, for a short circuit. Due to broken insulation, a short circuit quite often occurs, and the system ceases to function correctly.

- Check the connection between the controller and its ground.

- If you have a sensor with 4 wires on your car, you should check the integrity of the latter with a multimeter.

Please note that communication with the sensor will be interrupted when the car is stationary. Therefore, in this case, the diagnosis is performed while moving. It can be imitated by hanging the drive wheels.

Next, follow this algorithm:

- connect the laptop with diagnostic software to the vehicle diagnostic connector;

- turn on the ignition and run the test programs;

- select the speed display item;

- start driving so that the wheels rotate;

- compare the speed readings on the laptop and on the speedometer;

- if the parameters match, just reset the error, most likely this is an accident;

- if the readings are different, check the voltage in the dashboard;

- Next, the contacts and wiring going from the sensor to the ECU are checked;

- Since occasionally the speed sensor itself also fails, it should be checked with a multimeter for resistance and voltage.

Practice shows that most often the reason lies in a violation of the integrity of the insulation and short circuits. Or the sensor does not fit tightly enough to the contacts, which causes the accuracy of the transmitted signal to be impaired.

How to Test P0500 Speed Sensor

The connection diagram for different car brands will be different, but the general logic for checking the speed sensor will be the same. Let's consider the procedure on the Toyota RAV 4, a popular car in the domestic space. Diagnosis of the error must be performed using a special diagnostic tool. Depending on your model and software hardware used, some steps may vary. The algorithm has the following actions:

- Position the drive wheels so that they rotate freely.

- Connect the ECU connector and the diagnostic tool (laptop) to connector DLC3 using a signal cable.

- Turn on the ignition and the diagnostic tool. Select a menu in its program that shows the actual speed of the vehicle.

- “Drive” the car a short distance, while noticing the speedometer readings. Stop the spinning wheels. See what speed the program noted and compare them. If everything matches, then it is enough to reset the error programmatically; most likely it is an episodic operation.

- If the readings are different, the next step is to check the instrument panel for the voltage value. To do this, disconnect connector E22 (power) of the instrument panel and turn on the ignition.

- If everything is in order, then between ground and contacts E22-39 there will be a voltage in the range from 9 to 14 Volts. Note! This action must be checked both with non-rotating and rotating wheels. However, you need to rotate the wheels not with the help of the engine, but mechanically (manually, with the gearbox in neutral).

- Next, you need to measure the resistance of the wire between contacts E22-39 and A12-8, that is, check for opens and short circuits. The resistance of the specified wire according to the multimeter should not be lower than 1 Ohm and not exceed 10 kOhm. Otherwise, there is a wire break or short circuit (insulation damage).

- In rare cases, the controller malfunctions. If the voltage value is +12 V, then there is a short circuit to the power source. The controller may also fail. For additional diagnostics, it makes sense to start the engine, then touch ground with one probe and contact No. 2 of the wiring harness block from the sensor with the other. In this case, you need to look at the readings of the diagnostic device (program). If the speed value there is indicated as 0 km/h, then the controller has failed.

- Under similar conditions, you need to check the voltage between ground and contact No. 1 of the harness block. If there is voltage there, good, otherwise the wire breaks or is damaged (its insulation often fails).

- Under similar conditions, you need to check the voltage between ground and wire No. 3 of the harness block. If there is voltage, it means the sensor is either completely faulty or has poor contact. If the voltage does not pass through the multimeter, the wires are broken.

Interestingly, in some cases, poor insulation may interfere with the speed sensor signal from other systems. For example, in Toyota Camry cars, the described problem occurs when there is interference from parking sensors located nearby in the wiring harness. Therefore, it makes sense to inspect and check not only the insulation of the sensor wires and its system, but also others located in close proximity to it.

A more detailed check of the sensor involves the use of an oscilloscope. With its help, you can find out not only whether information is coming from different sensors of the drive wheels, but also look at the signal shape. And in some cases, the shape can be used to judge the operation of the ABS system. There are known cases when the ABS ring on one or the other drive wheel began to rotate itself, that is, to work out of synchronization with the CV joint. And this leads to a situation where the ECU receives false information. And in some cases (but not always, it depends on the ECU firmware), such a situation is the direct cause of error P0500.

On what cars does it occur?

When choosing a new or used car, the buyer thinks about the practicality, reliability and safety of the purchased car.

There is no way to guarantee that error P0500 will never appear on a particular car.

Error P0500 appears only on those vehicles that are equipped with an ABS system.

Therefore, it is far from a fact that your VAZ 2107 or UAZ may encounter error P0500. The same cannot be said about cars from the following list:

- Toyota Avensis.

- Chevrolet Captiva.

- Ford Focus 2.

- Lada Kalina.

- Lada Priora

- Suzuki SX4.

- Renault Megane.

- Toyota Camry.

- Lada Granta, etc.

Installing a new speed sensor

It is somewhat strange to observe that a recognized reliable car of the Toyota Avensis level and a budget domestic car Lada Priora appear on the same list. But the fact is that in both cases, a P0500 code is quite likely.

The only question is the reliability of the sensor and the quality of the components used. Here the obvious superiority is on the side of more expensive cars. But they are not protected from error P0500 appearing on the diagnostic scanner.

The P0500 error itself is quite serious. It is not recommended to continue operation if it is detected. It’s better to send the car to a service center or do the repair work yourself. Error P0500 is eliminated by carrying out appropriate manipulations, which depend on the reasons for writing the code in the ECU memory.

If error P0500 still appears, do not delay repairs. In addition, the ABS system will not work at this time. And this is potentially dangerous, because without an anti-lock braking system, in some cases, when the driver is accustomed to relying on it, it is possible to lose control.

Codes related to P0500

- P0501 - Speed Sensor Range/Performance.

- P0502 - Speed Sensor "A" Low Output.

- P0503 - Speed Sensor "A" Intermittent/Intermittent/High Signal.

- https://DriverTip.ru/repair/chto-oznachaet-oshibka-p0500.html

- https://obd2-codes.ru/p0500

- https://elm3.ru/diagnostika/oshibka-p0500

- https://etlib.ru/blog/876-oshibka-r0500

- https://www.drive2.ru/l/530199076516399034/

- https://autotime.net.ua/oshibka-p0500-vaz-neispravnost-datchika-skorosti-avtomobilya/

- https://voditelauto.ru/%D0%BE%D1%88%D0%B8%D0%B1%D0%BA%D0%B0-p0500/

- https://autotime.net.ua/oshibka-p0500-toyota-neispravnost-datchika-skorosti-avtomobilya/

Sources

[collapse]