Technical description and interpretation of error P2118

OBD-II Trouble Code P2118 is one of the possible codes that indicates that the powertrain control module (PCM) has detected a throttle actuator control motor current performance range mismatch problem. Therefore, the operation of the throttle actuator control system is limited.

The electronic control system uses data from multiple sensors to control, control and monitor throttle position. The main sensors in these systems are usually the accelerator pedal position and throttle position sensors. Which generate signal voltages which are used to activate the stepper motor in the throttle body.

The built-in throttle position sensor monitors throttle position. This information is used to correlate pedal position with actual throttle position. The PCM compares the actual throttle position relative to the desired or target position based on current operating conditions.

Therefore, when the PCM detects any abnormality in any involved throttle control system component. Which may affect the safe and reliable operation of the electronic throttle control system, it will set code P2118.

This error occurs when a throttle actuator control module performance problem is detected. In this case, there was a discrepancy in the operating range of the control motor current.

Reasons for the error

Code P2118 may mean that one or more of the following problems have occurred:

- Open or short circuit in the throttle actuator control circuit or related systems.

- Faulty throttle valve actuator due to mechanical wear of the drive gears.

- Excessive carbon deposits on the throttle valve.

- Failed pedal position sensor.

- Faulty throttle position sensor.

- Sometimes the cause is a faulty PCM.

Diagnosis and problem solving

The first step is to check the technical service bulletins (TSBs) for your specific vehicle. Your problem may be known to have a known fix released by the manufacturer. This can save you time and money during diagnosis.

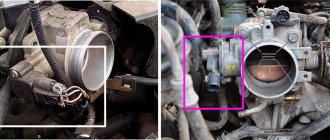

Next, locate the throttle actuator on your specific vehicle. This drive is usually installed at the front of the engine. On top of the engine, inside the wheel arches or against the bulkhead.

Wiring testing

Once found, visually inspect the connector and wiring. Look for scratches, scuffs, exposed wires, burn marks, or melted plastic. Disconnect the connector and carefully inspect the terminals inside the connector.

See if they look burnt or have a green tint indicating corrosion. If you need to clean the terminals, use electrical contact cleaner and a plastic bristle brush. Let dry and apply electrical grease where the terminals touch.

If you have a diagnostic scan tool, clear the DTCs from memory and see if the P2118 code returns. If it doesn't, it's likely a connection issue.

Checking the drive

If the P2118 code returns, we will need to test the drive and its associated circuits. There are usually 2 wires on each throttle actuator. First, disconnect the harness coming from the throttle valve actuator.

Using a digital multimeter, connect one lead of the meter to one terminal of the drive. Connect the remaining meter lead to another drive terminal. It must not be open or shorted.

Check the resistance specifications for your specific vehicle. If the drive is short-circuited, there will be infinite or no resistance at all. In this case, replace the throttle valve actuator.

If this test passes, use a multimeter to verify that you have 12 volts in the throttle actuator power supply circuit. Red wire to the drive power circuit, black wire to ground.

Using a scan tool that can activate the throttle actuator, engage the actuator. If there is no 12 volts at the actuator, repair the wiring from the PCM or relay to the actuator. Also in this case, the PCM may be faulty.

If everything is ok, make sure you have a good ground at the throttle actuator. Connect the test lamp to the 12 V battery positive (red terminal). And touch the other end of the test lamp to the ground circuit. The throttle actuator circuit going to ground.

Using a scan tool to operate the throttle actuator. Check to see if the warning light comes on each time the scan tool operates the actuator.

If the test light does not come on, this indicates a faulty circuit. If it lights up, move the wiring harness going to the drive. To see if the indicator light is flashing, indicating an intermittent connection.

If all previous tests pass and you continue to receive error P2118. Most likely, you have a faulty throttle actuator. Although a failed PCM cannot be ruled out until the throttle actuator is replaced.

If you are unsure, consult a qualified automotive diagnostician for assistance. To install the PCM correctly, it must be programmed or calibrated for a specific vehicle.

How to diagnose an engine?

Toyota Corolla self-diagnosis will allow you to figure out the source of problems in your car. Let's figure out where to start, what the error codes are and how to carry out diagnostics without special instruments and tools right in the garage.

First thing

All Toyota models older than 1988 are equipped with a multi-pin connector for diagnostics, which is located under the hood near the battery or on the left side of the car (along the way). The connectors are called DLC-1 and DLC-2. Option with index 1 is a plastic box, which is often marked “Diagnostic”. In this case, error codes are displayed directly through the “check” icon, located in a visible place for the driver. If you have a restyled or modern model of Toyota Corolla, then the light bulb is in the form of an engine, but it is the same thing. The previous information concerned owners of gasoline cars, because... for diesel versions, instead of a separate light bulb, a candle incandescent light bulb is used: a picture in the form of a spiral.

After carrying out diagnostics on your own, errors in the event of an automatic transmission malfunction are displayed through the “AT Check”, “Power” or “OD” lamps. Failures in other systems, for example, TRS or SRS and ABS, are displayed on the corresponding lamps.

Trouble P2118 - Throttle Actuator Motor Current Range/Performance

Trouble code P2112 is a general trouble code that indicates that the engine control module (ECM) has detected a malfunction in the throttle actuator control system. It should be noted that other throttle related errors may also appear along with P2112.

Typically, when P2112 appears, it means that the throttle valve is stuck closed, preventing air from entering the intake manifold. When this error occurs, the Check Engine light on the vehicle's dashboard will light up, indicating a malfunction. The ECM can also put the vehicle into limp mode to prevent further damage. The vehicle will remain in this mode until the error is resolved.

Symptoms of malfunction

The main driver symptom of P2118 is the MIL (Malfunction Indicator Light) illumination. It is also called Check engine or simply “check light”.

They can also appear as:

- The “Check engine” warning light on the control panel will light up (the code will be stored in memory as a malfunction).

- Other related trouble codes may also be present.

- Transition of the vehicle to fail-safe or emergency mode.

- The engine cannot be accelerated and the throttle response is unresponsive.

- The automatic transmission does not shift.

- The engine stalls or has trouble starting.

- Reduced engine power.

- Black smoke from the exhaust pipe.

- Increased fuel consumption.

The severity of this code can range from moderate to severe depending on the specific problem. Therefore, it is worth paying close attention to it.

Description and meaning of error P2118

This generic powertrain diagnostic trouble code (DTC) typically applies to all OBD-II equipped vehicles that use a throttle control system to drive - wire including but not limited to vehicles from Toyota, Honda, Hyundai, Lexus, Volvo, Scion, Nissan, Kia, etc . OBD-II Trouble Code P2118 is one of several possible codes that indicates that the Powertrain Control Module (PCM) has detected a malfunction with the throttle control system operation. There are 6 codes that are associated with malfunctions of the throttle actuator control system and they are P2107, p2108, p2111, p2112, P2118 and P2119. Code P2118 is set by the PCM when the Throttle Actuator Servomotor is out of range or not operating properly. The PCM monitors the throttle actuator control system by monitoring one or more throttle position sensors. Throttle body operation is determined by the position of the throttle plate, which is controlled by one or more throttle servomotors. The PCM also monitors the accelerator pedal position sensor to determine how fast the driver wants to go and then determines the appropriate throttle response. The PCM accomplishes this by changing the current flow to the throttle actuator control motor which moves the throttle plate to the desired position. Certain malfunctions can cause the PCM to limit the operation of the Throttle Actuator Control System. This is known as fail-safe or limp mode, where the engine is held at idle or may not start at all.

On which cars is this problem most common?

The problem with code P2118 can occur on different machines, but there are always statistics on which brands this error occurs more often. Here is a list of some of them:

- Citroen (Citroen C4)

- Dodge (Dodge Avenger)

- Honda

- Hyundai (Hyundai Solaris, Elantra)

- Kia (Kia Optima, Rio, Sid, Sportage, Forte, Cerato)

- Lexus (Lexus gs300)

- Mazda

- Nissan (Nissan Pathfinder)

- Opel (Opel Astra)

- Scion

- Suzuki (Suzuki Verona)

- Tata

- Toyota (Toyota Avensis, Verso, Camry, Corolla, Land Cruiser, Prius, Rav4, Highlander)

- Volvo

With fault code P2118, you can sometimes encounter other errors. The most common ones are: P0030, P0135, P2101, P2107, P2108, P2110, P2111, P2112, P2119.

Error P0172 - Fuel system too rich

Error P0172 is due to the fact that the mixture is supplied to the cylinders too rich. This is accompanied by the following symptoms:

To solve the problem you need to check:

First of all, check the mass air flow sensor - MAF. How to check the sensor using a multimeter, read the article at the link.

There is a high probability that the sensor is transmitting incorrect data, which is why a rich mixture is supplied to the cylinders. It is especially important to pay attention to the sensor if there is also a P0102 error.

MAP pressure sensor

The MAP sensor can also be the cause of error P0172. Check the sensor:

Air leak

Check for air leaks after the mass air flow sensor. Leaks often occur due to the receiver's corrugation not being fully tightened. It is recommended to spray soapy water on the parts where air passes through. Places where air passes will become noticeable. If the air leak is eliminated, reset the errors. P0172 should no longer appear.

Fuel injectors

The next thing to check is the fuel injectors. First check if voltage is supplied to each of them. There are special stands for checking injectors, but as a rule, they cannot be found in every city.

Air filter

Check and replace the air filter if necessary.

Throttle valve

Check the throttle sensor. For this

If the resistance is different, the TPS must be replaced.

Absorber valve

The canister valve is controlled by the ECU. the valve could open and hang in such a position, which creates excess air leaks, which leads to P0172.

The error “Fuel supply system too rich” most often appears in VAZ cars, in particular Kalina, Priora. And also in a number of others: Ford, Opel, Mercedes

Other OBD2 errors

How to fix P0335?

Inspect the flywheel teeth and timing belt. Replace it if necessary.

Disconnect the harness and inspect all wires connected to the DPKV for damage, make sure that all connections are intact. Test the wires with a multimeter. To do this, first turn on the ignition, but do not start the engine. Touch the black wire of the multimeter to the body of the machine, and examine the connector pins one by one with the red wire. There should be a voltage of 5 V on one of the connectors. If you do not find such a connector, then the harness is damaged.

The DPKV itself fails rarely. Typically, code 0335 indicates a malfunction not in the sensor itself, but in the circuit associated with it. But if it fails, it cannot be repaired. Unscrew the single bolt and pull out the device. Inspect it for metal shavings and other damage. The sensor may have failed and needs to be replaced.

If the device is externally intact, check it with a multimeter, having previously set the ohmmeter mode. Infinity will indicate a break in the network, and 0 indicates a short circuit. The ohmmeter readings must correspond to those indicated in the technical passport. If there are deviations, then the sensor has a problem.

If error 0335 is not corrected in time, it can lead to more serious problems in the engine. And in order not to end up with a stalled engine somewhere where there are no emergency services, it is necessary, when information about a DPKV error appears, to diagnose the car yourself, or go to a car service center, where the faults will be eliminated quickly and professionally.

Additional comments for troubleshooting error P2112

The most common cause of a stuck open or closed throttle body is excessive carbon buildup on the throttle body. In this case, the problem can be solved by cleaning the throttle body using a special cleaner. In some cases, the cause of a stuck throttle valve is wear or malfunction of the throttle valve itself.

It should be noted that in order to properly diagnose the P2112 error code, you will need an advanced OBD-II scanner, which allows you to not only read stored error codes, but also view data from various sensors in real time.

How to Troubleshoot or Reset Trouble Code P2118

Some suggested steps to troubleshoot and fix error code P2118:

- Diagnose the code according to the manufacturer's verification test to check the signal.

- Clear the error codes from your computer's memory and test drive the vehicle to see if the P2118 code appears again.

- Using the accelerator pedal, check the throttle position sensors and drive operation.

- Inspect the accelerator pedal as well as the throttle valve for sticking in the open or partially open position.

- Check the harness and connection visually for problems, and correct problems if necessary.

- Test the actuator according to the manufacturer's specified spot test.

- If no problem is found, the engine control module (PCM) must be inspected and replaced if necessary.

Troubleshooting error P2121 SFI 1AZ-FE TOYOTA RAV4 / ACA30, ACA33, ACA38 ALA30

DTC P2121 Pedal/Throttle Position Sensor "D" Circuit Malfunction Due to Out of Range/Invalid Parameter Value

HINT: Refer to DTC P2120 (See page Click here).

Emergency function

The APP sensor has two circuits (main and auxiliary). If a malfunction occurs in one of the sensor circuits, the ECM detects the erroneous voltage difference between the two sensor circuits and switches to emergency mode. This mode uses a functioning circuit to detect the position of the accelerator pedal, allowing you to maintain vehicle control. If both circuits fail, the ECM considers the accelerator pedal to be fully released. As a result, the throttle valve closes and the engine idles. When a normal state is detected and the ignition is turned off, the emergency operation mode is terminated and the system returns to its normal state.

CONNECTION DIAGRAM

Refer to DTC P2120 (See page Click here).

TEST SEQUENCE

HINT: Use a handheld diagnostic tool to read the fixed parameters. These parameters reflect the state of the engine at the time the malfunction was detected. When troubleshooting, fixed parameters allow you to determine whether the car was moving at the time of the malfunction or not, whether the engine was warmed up, what the air-fuel mixture was (lean or rich), etc.

HINT: If any codes other than P2121 are displayed, troubleshoot these DTCs first.

Proper diagnostics

The Toyota Corolla diagnostic system consists of sensors that record the physical parameters of components, an electronic control unit (ECU), a program for this unit, as well as a fault indication system.

Initially, the manufacturer entered the reference values of the state parameters of the vehicle components into the ECU memory. During operation, the sensors record the actual values of these parameters and then send them to the electronic control unit. The Corolla ECU compares the received actual parameters with the reference values and, if they do not match, writes a code into memory. After this, the control unit sends an error code to the Toyota Corolla “CHECK” indicator light. When the fault is corrected, the error signal disappears. In addition, it is possible to force the reading of fault codes with or without a scanner.