An automatic transmission is one of the important and structurally complex components of a car, which includes a huge number of different elements, sensors, microcircuits, etc.

Failure of at least one of them entails serious problems in the operation of the automatic transmission. For example, the occurrence of “kicks” when switching from first gear to second may be associated with a malfunction of an element such as an automatic transmission step-down resistor.

Step-down resistor and automatic transmission kicks

When changing gears at high speeds, the car was kicked in the butt, which of course was annoying, the kicks were especially annoying when switching from 1st to 2nd gear, the kicks were not strong, but they were there.

I noticed that the strength of the kicks depended on the driving time, the longer the trip, the stronger they were, as it turned out later, the step-down resistor heats up from the current passing through it and begins to work incorrectly.

This method is suitable not only for Nissan Cefiro cars but also for all others!

Signs of a faulty pull-down resistor

First, let's figure out why a step-down resistor is needed. The main function of a step-down resistor is to reduce the current on the control valve of the main line of the automatic transmission, the so-called line pressure solenoid. To put it more simply, a resistor is needed so that the brains of the automatic transmission soften the gear shift. If you turn off the reduction resistor, the speeds will switch at the maximum pressure that the automatic transmission oil pump can create, hence the kick when switching from 1st to 2nd gear.

A pull-down resistor in good condition should output between 11.2 ohms and 12.8 ohms . Also, the resistor can heat up during operation, especially if it asks for replacement; there is no point in trying to cool it with some improvised methods - it’s easier to buy a new one, it heats up from the current passing through it.

If your automatic transmission kicks from 1st to 2nd gear, especially at high speeds, but otherwise does not bother you with its operation, then you can most likely use a step-down resistor.

How it works?

As already mentioned, a modern automatic transmission is equipped with artificial intelligence in the form of a control unit. This unit collects readings from various car components in order to change acceleration characteristics. Many have noticed that the transmission has a memory of driving style: during sharp acceleration, the automatic transmission changes gears at higher speeds and somewhat sharper.

One of the parameters that changes depending on the remembered driving style is the speed of gear shifting. The faster the gear changes, the more the driver and passengers in the cabin feel it.

In turn, the speeds are switched due to oil pressure, which moves the clutches and connects them in various combinations. The pressure is affected by the solenoid, which can open more quickly or, conversely, more smoothly. If the opening occurs quickly, then the maximum possible oil pressure will act on the clutches, and due to this, the speed will change quickly and sharply.

How quickly the solenoid opens is affected by the voltage applied to it. In this regard, it was necessary to introduce into the existing design an element that could affect the operation of the solenoid.

The system works like this. The electronic unit sends a command to the resistor. That, in turn, is connected in an electrical circuit to the solenoid. The voltage supplied through the resistor is sensed by the solenoid and it opens to the required extent. The oil, which flows under regulated pressure, makes a gear change, and the car moves on, and the next time it changes, the process is repeated.

A step-down resistor can influence the operation of the machine and change its operating mode. If switching occurs too abruptly or slowly, it is worth paying attention to this particular functional unit and diagnosing it.

Replacing the pull-down resistor

First of all, it must be said that the native step-down resistor has the following characteristics: 10 W, 12 Ohms .

You can replace it with anyone whose characteristics are no worse. We purchased a 25 W, 12 Ohm power resistor in a housing (cost 160 rubles).

Old pull down resistor

Changing the resistor is quite simple; it is located in the engine compartment, behind the air filter housing; removal and installation takes no more than 10 minutes. First you need to disconnect the cold air intake pipe, then unscrew the 5 bolts holding the air filter housing.

After removing the old resistor, you need to carefully cut the wires - as close to the base as possible, otherwise you will have to buy new ones and do even more collective farming, and we will solder a new step-down resistor from a chip and a dip to them.

The old one was in a ceramic case and, apparently, was installed in Japan, apparently we were the first to go there, but it was good, we used it as a stand because... It was more convenient to solder on it.

The new step-down resistor fit into the old case as if it were original, and it was secured. Of course it doesn’t look so nice, but that’s not the main thing, the main thing is that it works.

We immediately went to check the operation of the automatic transmission, especially the kick from 1st to 2nd gear and shifting at higher speeds. We accelerate and catch a shift from 1st to 2nd gear at high speeds, it shifted very smoothly, now from 2nd to 3rd gear, it also shifted smoothly, the problem with the step-down resistor has been solved.

Source

Where is the automatic transmission reduction resistor located?

An automatic transmission is one of the important and structurally complex components of a car, which includes a huge number of different elements, sensors, microcircuits, etc.

Failure of at least one of them entails serious problems in the operation of the automatic transmission. For example, the occurrence of “kicks” when switching from first gear to second may be associated with a malfunction of an element such as an automatic transmission step-down resistor.

Why do you need an automatic transmission reduction resistor?

To understand where the automatic transmission step-down resistor is located and why it is needed, let's look at this element in more detail. Today, almost all automatic transmissions are equipped with reduction resistors.

The reduction resistor, being one of the components of the automatic transmission, is responsible for smooth (without jerking) gear shifting from first speed to second.

Externally, this radio element is very similar to elements installed on household appliances. To protect the resistor from moisture and dirt, it is installed under the hood of the car, not far from the automatic transmission housing. This element has additional small protection in the form of a “visor” (shield).

Depending on the design features of the car, the automatic transmission resistor can be located in different parts of the body. For example, in NISSAN cars, the automatic transmission resistor (“drop resistor”) is located under the air filter in a metal case attached with two bolts.

In this case, the lowering resistor, having received an impulse from the electronic control unit, transmits voltage to the solenoid that controls the pressure in the automatic transmission circuit. Thus, the resistor influences how far the solenoid opens.

In turn, transmission fluid flowing under pressure contributes to smooth gear shifting in the gearbox. This is the work of a step-down resistor, the function of which is to adjust the smoothness of switching speed modes by sending a switching pressure control signal.

High-speed gearboxes (automatic transmission)

Toyota supports the installation of Aisin automatic transmissions. There is a shift lock button on the automatic transmission. Its main function is to launch the transmission unlocking mechanism when the power plant is turned off. Overdrive is an overdrive gear. It is activated when driving on highways. Cars that can support automatic transmission installation:

- Toyota Corolla.

- Toyota RAV4.

- Toyota Avensis.

- Toyota Auris.

- Toyota Hilux.

Gearbox model A540E

The Toyota Camry supports the installation of the A540E model gearbox. In this case, special attention should be paid to the torque converter and oil system. The box can withstand heavy loads well.

Toyota cars are equipped with a step-down resistor. Where is the pull down resistor located? On a foreign car, the automatic transmission reduction resistor is located behind the air filter (has a metal housing). Its function is to control the pressure of the oil poured into the gearbox when changing speeds. In the event that the machine begins to “kick”, it is necessary to diagnose the resistor.

Automatic transmission U341F

The U341F gearbox was created for the Corolla model. As a rule, it is designed for 4 stages. The main distinguishing feature of this unit is endurance. Automatic transmissions Toyota A340 and A440 have a long service life. They can be found on the Toyota Land Cruiser model. If you adhere to a measured travel style and do not neglect maintenance, the gearbox will last several hundred thousand km.

Article on the topic: VAZ 2114 gearbox - what is it?

Failure of the automatic transmission step-down resistor and methods for troubleshooting

Problems such as jerking or kicking when shifting from first to second gear do not always require a complex solution. Most likely, the reason may be a failed step-down resistor.

Troubleshooting methods:

Please note that if the problem cannot be resolved on your own, you must contact a service station to carry out a full diagnosis and identify the breakdown. Perhaps the problem of hard gear shifting is not related to the automatic transmission reduction resistor.

Causes of automatic transmission malfunction - typical

Lever links

In old-type automatic transmissions, which had a mechanical connection of the selector directly with the transmission, the automatic transmission lever often fails, which makes it impossible to change the operating modes of the transmission. The repair in this case consists of replacing the broken selector and gearbox rocker. Such breakdowns manifest themselves as difficulty in moving the automatic transmission selector. Ultimately, the lever stops moving and the automatic transmission needs to be repaired. For some modifications of automatic transmissions, this work can be carried out without removing the gearbox itself from the car, which somewhat simplifies repair work.

Oil is leaking

A common malfunction of an automatic transmission is the presence of oil leaks from under the sealing gaskets. That is why the car owner is recommended to regularly inspect the condition of the gearbox on a lift or garage pit. If there are any oil leaks on the gearbox itself, you should contact experienced specialists. In this case, eliminating such problems is not particularly difficult and consists of replacing the gaskets and changing the transmission oil.

Regularly inspect your vehicle for leaks on the pallet.

Control block

In some cases, there may be problems with the transmission control unit. The control unit may incorrectly select the speed to change gears or independently block the operation of the transmission. Elimination of breakdowns associated with the operation of the control unit and the electrical part of the transmission consists of replacing failed units and control loops.

Problem with the ECU (control unit) - solved by replacing the unit

Problems with the valve body

Such malfunctions can occur in a number of cases. For example, improper operation of the gearbox. When the car enthusiast does not warm up the machine, but immediately starts driving. Symptoms: vibrations, shocks, impacts. In some cases, the car refuses to move. On modern cars, a malfunction with the GB is signaled on the on-board computer.

Torque converter problem

Such problems can only be resolved by repair. In general, such work is cheaper than work on the valve body and ECU. The symptoms are: knocking, rustling sounds, vibration, car dynamics suffer, when changing the oil in the box, there are copious amounts of chips in the pan.

What's the result?

In cars equipped with an automatic transmission, in case of various problems (in this case, problems when switching from first to second gear), the culprit may well be electronics.

Finally, we note that in the event of such failures, the ECU often turns on the automatic transmission emergency mode program. In this mode, third gear will automatically engage; there is no switching to others. In this mode, the driver has the opportunity to safely get to the service station under his own power, after which specialists will carry out a full diagnosis and fix the breakdown.

The main sensors in an automatic transmission: the purpose and operating principle of automatic transmission sensors. Malfunctions of automatic transmission sensors, signs.

How to determine that the automatic transmission is overheating: signs indicating overheating of the automatic transmission. How to improve automatic transmission cooling and prevent the machine from overheating.

Automatic transmission input shaft speed sensor: what is the specified automatic transmission sensor for, signs of its malfunction, diagnostics.

Automatic transmission solenoid: design of solenoids, operating principle. Frequent malfunctions and breakdowns of solenoid valves, diagnostics, repair and replacement.

Automatic transmission ECU: how the electronic control unit of an automatic transmission works and works. Malfunctions of the automatic transmission ECU, repair of the control unit.

Typical automatic transmission faults | Causes of machine failure | Symptoms

During the operation of the car, a significant load is placed on the automatic transmission, which leads to breakdowns of this unit. In recent years, automakers have been using fairly reliable and modern automatic transmissions, which has significantly reduced the number of such transmission breakdowns. In most cases, automatic transmissions used today, with proper operation and timely maintenance, may require major repairs after a mileage of no earlier than 150,000 kilometers. The first thing diagnostics begins with is the removal of computer fault codes and their subsequent decoding. Then, ideally, contact a specialist for a more accurate diagnosis.

Content :

Step-down resistor and automatic transmission kicks

Preface When changing gears at high speeds, the car was kicked in the butt, which of course was annoying, the kicks were especially annoying when switching from 1st to 2nd gear, the kicks were not strong, but they were there. I noticed that the strength of the kicks depended on the driving time, the longer the trip, the stronger they were, as it turned out later, the step-down resistor heats up from the current passing through it and begins to work incorrectly. This method is suitable not only for Nissan Cefiro cars but also for all others!

Signs of a faulty pull-down resistor

First, let's figure out why a step-down resistor is needed. The main function of a step-down resistor is to reduce the current on the control valve of the main line of the automatic transmission, the so-called line pressure solenoid. To put it more simply, a resistor is needed so that the brains of the automatic transmission soften the gear shift. If you turn off the reduction resistor, the speeds will switch at the maximum pressure that the automatic transmission oil pump can create, hence the kick when switching from 1st to 2nd gear.

A pull-down resistor in good condition should output between 11.2 ohms and 12.8 ohms . Also, the resistor can heat up during operation, especially if it asks for replacement; there is no point in trying to cool it with some improvised methods - it’s easier to buy a new one, it heats up from the current passing through it.

If your automatic transmission kicks from 1st to 2nd gear, especially at high speeds, but otherwise does not bother you with its operation, then you can most likely use a step-down resistor.

Replacing the pull-down resistor

First of all, it must be said that the native step-down resistor has the following characteristics: 10 W, 12 Ohms . You can replace it with anyone whose characteristics are no worse. We purchased a 25 W, 12 Ohm power resistor in a housing (cost 160 rubles). New step-down resistor Old step-down resistor Changing the resistor is quite simple, it is located in the engine compartment, behind the air filter housing, removal and installation takes no more than 10 minutes. First you need to disconnect the cold air intake pipe, then unscrew the 5 bolts holding the air filter housing. After removing the old resistor, you need to carefully cut the wires - as close to the base as possible, otherwise you will have to buy new ones and do even more collective farming, and we will solder a new step-down resistor from a chip and a dip to them.

The old one was in a ceramic case and, apparently, was installed in Japan, apparently we were the first to go there, but it was good, we used it as a stand because... It was more convenient to solder on it.

The new step-down resistor fit into the old case as if it were original, and it was secured. Of course it doesn’t look so nice, but that’s not the main thing, the main thing is that it works. We immediately went to check the operation of the automatic transmission, especially the kick from 1st to 2nd gear and shifting at higher speeds. We accelerate and catch a shift from 1st to 2nd gear at high speeds, it shifted very smoothly, now from 2nd to 3rd gear, it also shifted smoothly, the problem with the step-down resistor has been solved.

Automatic transmission kicks: reasons

There are many mechanisms in an automatic transmission - therefore, there are many probable reasons why the automatic transmission kicks. How do you know where to look for them? If the problem appears in winter, it is most likely due to insufficient engine warming up. If the box jerks when moving, it is worth looking for a fault in the wiring. If there are constant shocks, check the gearbox - it is quite possible that it will depressurize.

It's all about the oil

The automatic transmission oil must be changed every 100-150 km. Otherwise, the gearbox will not function properly. Oil is an important element for high-quality transmission of torque between the parts of the torque converter. It should be selected based on the brand of transmission installed on the machine. When the machine is used for a long time, the oil heats up, as a result of which it becomes less viscous and no longer transmits torque as reliably.

Along with the transmission oil, you also need to change the filter. It contains chips that can get into the new oil. By the way, due to oil contamination, the pressure in the system decreases, so the clutches cannot stop in time.

The problem is in the clutches

The transmission box contains discs that are responsible for the operation of certain gears. When the pressure drops, the clutches begin to slip, turn black, and when you disassemble the box, you can smell a burning smell. The gears may not stop at the right time if the clutches are burned out.

Test the condition of the clutches like this:

- park your car on a straight lot;

- set the speed to “neutral”;

- release the brake pedal;

- if after this the car starts moving, this is a clear sign of burnt out discs.

This is a significant problem that will require complete disassembly of the transmission to resolve. Not every driver will be able to cope with this, so if you lack the skills, it is better to entrust this task to a specialist.

Radiator problems

Kicks in the automatic transmission can also occur due to the cooling radiator. If its operation is incorrect, this will certainly lead to overheating of the oil. During incorrect oil changes, the pipes become clogged. This happens due to the fact that the transmission fluid is usually changed under high pressure, which leads to debris settling in the pipes. Therefore, it is worth thinking carefully before deciding to change the ATF oil under pressure.

To minimize the risk of system clogging, during an oil change you need to change the filter and thoroughly rinse the pan. Follow this order to avoid shocks in the gearbox:

- remove the radiator and clean it thoroughly;

- change the filter;

- refill with new ATF fluid.

Follow these simple steps, and the problem will no longer appear.

The hydraulic unit is dirty

High pressure when changing ATF fluid leads to clogging of the hydraulic plate - the main transmission unit. Clogging of the node's channels will inevitably lead to a decrease in pressure in the box. It can return to normal only after cleaning the channels. And only on the condition that the other components are in good working order.

Problems with valves and wiring

There are valves on the hydraulic plate for supplying fluid to the channels. They operate on electricity, so the cause of their malfunction may be in the wiring. Sometimes valves simply break when they reach the end of their useful life. In gearboxes, solenoids with plastic housings are now being used. They can become deformed when exposed to high temperatures.

Damage to the valve system can only be repaired by disassembling the valve body. If the solenoids are faulty, they are replaced. When the gearbox breaks down, it kicks in a certain gear, which means the valve is jammed. The valve loses its ability to open.

But what malfunctions can lead to a lack of impulse in the wiring:

- contacts have oxidized;

- there was a break;

- Carbon deposits have formed on the contacts.

Start your diagnosis with the wiring. The problem may be in a very ordinary break, which you will not immediately notice, so be more careful during the inspection. If the wiring is OK, try ringing the step-down resistor. Its usual location is behind the air filter. The step-down resistor often breaks down, and if the ohmmeter shows this, the part should be replaced.

Oil pump

Keep in mind that automatic transmission kicks can be caused by a broken oil pump. True, this rarely happens. The pump is checked only after changing the filter and cleaning the radiator. The pump can be located behind the hydraulic unit or on a pallet.

When the automatic transmission kicks

Automatic transmission kicks –

This problem is typical for many cars that have an automatic transmission. Many drivers panic if they discover a similar phenomenon on their steel horse. However, you should not give in to panic, because in fact there can be a huge number of reasons and not all of them are terrible. Let's try to figure out the main reasons that lead to the automatic transmission starting to kick, and find out how to deal with this phenomenon. So, it’s worth starting with the most common case, when the automatic transmission kicks when mode D is turned on. This is the most common case, and a similar problem affects almost all cars with automatic transmissions installed.

A similar problem can occur when switching to a cold or heated box. In both cases there may be several reasons.

For example, the time has come to simply change the oil in the automatic transmission. Also, don’t forget about the filter. These measures do not always help, but if the automatic transmission kicks, it’s worth starting with them. If the automatic transmission continues to bother you, then it is best to conduct a full diagnosis. For this purpose, there are many specialized centers staffed by people who know a lot about “machines”. If we are talking about switching to D on a hot engine, then it is quite possible that the hydraulic plate will have to be repaired. That is, the reason lies in the fact that the torque converter lock is jammed.

The automatic transmission also starts to kick very often when switching to reverse gear. There may also be several reasons for this. For example, the sensor on the box may not work. In this case, you should immediately go to the nearest service center for diagnostics. They will definitely help you solve the problem. However, the sensors are not always to blame. The automatic transmission may kick not because of the electronics, but because of the mechanics. Just as in the first case, you can try replacing the oil in the box and the filter. In approximately thirty percent of cases, this measure helps.

By the way, the sensors themselves are not always to blame; a problem with kicking may arise due to a malfunction of the connectors to which the sensors are connected. They are also worth checking out.

If the automatic transmission starts to kick when switching from one speed to another, then some of these actions may help:

Thus, a kicking automatic transmission is not a death sentence. It is quite possible that you simply need to change the oil and filter. It is always worth remembering that to eliminate the problem it is necessary to do a full diagnosis in a specialized service. Professionals will definitely help in solving such a complex problem. Of course, the car owner himself can handle the job, but only with special equipment and the appropriate knowledge and experience.

Video - perhaps this is where you should start checking and diagnosing in cases where the automatic transmission kicks:

May be of interest:

How to avoid problems?

It must be said that the causes of automatic transmission malfunction can be both objective in nature, caused by physical wear, and can be caused by improper operation of this unit. Many car owners neglect the need to regularly change transmission oil, which leads to problems with lubrication and constant overheating of the automatic transmission. As a result, the moving elements of the box quickly fail and require expensive repairs.

It is also necessary to properly warm up the transmission in the winter, which will eliminate problems with lubrication of the moving elements of the transmission. Low-quality oil damages solenoids, the replacement of which is difficult and expensive. It should also be remembered that automatic transmissions are extremely critical to aggressive driving style. When the engine operates for a long time at maximum speed, the clutches of the automatic transmission can quickly burn out and wear down. That is why it is not recommended to constantly practice an aggressive driving style in a car with an automatic transmission.

The difficulty of repairing automatic transmissions is due to the fact that the failure can only be determined by opening the transmission. To do this, it must be removed from the car, which will allow us to determine the nature of the breakdown. It is not possible for most ordinary motorists to carry out high-quality repairs of an automatic transmission on their own, so it is necessary to contact specialized service centers. Repair work consists of replacing damaged elements, which allows you to restore the functionality of the entire automatic transmission. It should be noted that due to the structural complexity, automatic transmission repair is labor-intensive and high-cost.

How to determine the condition of the automatic transmission yourself - Video

Car service technicians distinguish

3 levels of diagnostics:

1. Quick diagnostics - “Hear”

From the driver’s confused, hasty story, symptoms of a mild malfunction appeared like: “clean the oil from the sensor” or “check the cable that powers the ECU and solenoids” - this is, as a rule, a free diagnosis. But there may be a more serious problem, threatening major repairs with disassembly, but this is a different level.

Self-medication here can be a regular oil change in the automatic transmission or setting the optimal oil level. This happens with four-speed engines that have traveled about 200,000 km.

2. Tactile level - “Touch”

At this level, a routine circuit check may help. This is a matter of a few minutes. A more serious problem can be identified by removing the pan. This is all inexpensive automatic transmission diagnostics.

Also, without dismantling, specialists can make a diagnosis using: a table test, checking the pressure on the line, checking the serviceability of the electrical wiring and reading fault codes.

Self-medication here is the same as in the first case - topping up or completely changing the oil.

If the automatic emergency mode (permanent 3rd gear) or any other fault listed below is obvious, then disassembly is necessary for a more accurate diagnosis. This is typical for boxes that have traveled more than 200,000 km. This mileage is approaching the time to replace the gas turbine clutch.

Troubleshooting with 100% accuracy will only be achieved by “opening” the automatic transmission.

Where is the reduction resistor of a car automatic transmission located?

Home » News Published: 08/24/2018 How to eliminate shocks in an automatic transmission Today, almost all automatic transmissions are equipped with a reduction resistor, thanks to which the car moves without jerking when switching the automatic transmission. In appearance, it differs little from the elements used in household appliances, and it is not difficult to find the device. Did you know? The unit of electrical resistance is named after Georg Simon Ohm, the founder of the law of electrical circuits.

Functions of an automatic transmission step-down resistor

The operating procedure and gear shifting in an automatic transmission are controlled by the transmission ECU. The control unit sends impulses to radio elements, which can change their performance and affect the operation of the gearbox. A resistor is one such element. Elimination of kicks when switching automatic transmission MAZDA-FORD-NISSAN-HONDA. Using the Mazda 6 GG as an example. Under operating conditions, this part is connected to the solenoid (pressure control valve in the gearbox line). The electronic unit sends a pulse to the resistor, which, in turn, transmits voltage to the solenoid and opens it to the desired limit. Oil flowing under pressure smoothly changes the speed mode of the car. This is the main function of the automatic transmission reduction resistor - to adjust the smoothness of gear shifting and ensure driving comfort. TOYOTA RAV4 | Why does the automatic transmission kick, jerk, and push? When switching

Urgency

Currently, almost all transmissions are equipped with a step-down resistor. Externally, such a resistor on an “automatic machine” is practically no different from those used in household appliances, and therefore finding it is not difficult.

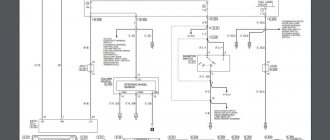

It should be noted that this radio element can be located in various parts of the body, which is easily explained by the design features of cars. However, armed with an automatic transmission diagram, it is quite easy to find such an element: the main thing is not to damage the complex transmission circuit or any other functional elements of the car when searching for it.

Practice shows that most often the automatic transmission resistor can be found under the hood. This is quite natural, because this part of the car body is carefully protected from precipitation and moisture, which is favorable conditions for the operation of electronics. However, we should not forget that the specified radio element works specifically for the benefit of the automatic transmission, therefore it is located not far from its body. For example, in Toyota cars this important element is located under the air filter and has its own small shield that protects the electronics from dirt and moisture.

But why do you need a resistor in the automatic transmission? To understand this fully, you need to remember on what principle the automatic transmission operates and how its operating modes change.

For example, when the accelerator pedal is operated quite smoothly, acceleration is slow, and gear shifting is almost imperceptible to the driver. At the same time, when acceleration occurs sharply and the pedal moves to the “kick-down” mode, switching occurs quite quickly.

Of course, the operating modes and gear shifts in the automatic transmission are handled by the electronic control unit, that is, the artificial intelligence of the transmission. But all it can do is supply different voltages to radio elements, which, in turn, can change their characteristics and affect the operation of the automatic transmission. It is one of these elements that is the resistor, which is located in the car and serves to regulate the smoothness of gear shifting and, thus, make the driving comfort of the car optimal.

Overview of types and types of resistors

At the moment, almost every electronic circuit is assembled using a resistor. This element is necessary to ensure the normal functioning of electrical appliances. Moreover, it should be noted that at the moment no part has yet been invented that could perform the functions of a resistor. Due to the wide range of human needs, a huge number of resistors have been produced, differing in type and type. Variable resistors in the photo

Types according to OM and PTO

On the domestic market of radio equipment and related parts you can find the following types of resistors:

5 W resistor in the picture

Types and characteristics

In addition to the type differences, these parts also have a huge variety of species, which allows them to be used in many areas:

The picture shows an example of a wirewound resistor

Some of them should be considered in more detail.

SMD resistor in the photo In accordance with the standards, SMD resistors are usually designated on the electrical diagram in the same way as standard versions of parts of this type. It is the smallest element among all resistors. As for the typical sizes of elements of this type, they are significantly smaller than other resistors. But size does not affect the power characteristics. The power of SMD resistors varies from 0.05 to 1 W.

This type of resistor is in turn divided into the following group of subtypes:

The main thing when using parts is to understand exactly why they are needed on the diagram and what function they perform.

As already mentioned, resistors are widely used in various fields. This applies not only to the creation and design of various electrical devices, but also to improving human comfort. An electrical component of this type was “useful” for creating a heating device in a vehicle. For example, they are used for:

The picture shows a Ford Focus 2 heater resistor

Automatic transmission reduction resistor

To calculate a resistor to reduce the voltage, you must use the following mathematical formula: U=IR, where U is the voltage drop indicator; I – the strength of the electric current supplied to the resistor; R is the resistance of the resistor. It should be noted that the Toyota automatic transmission reduction resistor is located under and between the battery cradle and the fuse block. Particular attention should be paid to the reduction resistor of the Nissan automatic transmission. It is responsible for smooth gear shifting.

Cost of resistors

Currently, you can purchase resistors for creating electrical circuits both in specialized stores selling electrical elements and in general trade departments. You can also buy a resistor at repair shops. The cost of electrical parts of this type varies from 150 to 400 rubles. If we are talking about a resistor block, then its price can reach 6-8000 rubles.

Attention! The price of elements of this type directly depends on the technical characteristics.

Before directly purchasing a product, you must make sure that it is suitable and working. Especially for this purpose, the sales department should have a multimeter. Where to buy resistors in Moscow:

Where to buy resistors in St. Petersburg:

Video

Watch the video for a description of the color marking of resistors: If, when assembling the circuit yourself, questions arise regarding the method of installing the resistor, you must contact experienced specialists and craftsmen. In any case, before connecting the circuit to the power source, you will need to check everything carefully. Otherwise, there is a risk of electric shock. Oct 9, 2015 Tatyana Sumo

Physical definition

A resistor is an element used in an electrical circuit and does not require a power source for its operation.

It is designed to transform current into voltage and vice versa. In addition, it can convert electrical energy into thermal energy and limit the amount of current. But before calculating the voltage drop across a resistor, it is advisable to understand the essence of this process. A resistor is a very common element characterized by a number of parameters. The main ones are:

- resistance;

- the amount of energy dissipated;

- operating voltage;

- power;

- resistance to environmental influences;

- parasitic component.

A passive electrical element is indicated in the diagram as a rectangle with two terminals from the middle of its sides. In the center of the figure, power can be indicated in Roman numerals or dashes. For example, a vertical stripe indicates the element's withstand power of 1 W. The crossed out rectangle in the notation in the diagram indicates that such a resistor is variable.

Resistors can be produced with constant and variable resistance. A type of the latter are tuning elements. The only difference between them and variables is the way they are set to the desired value.

On diagrams and in technical literature, the device is designated by the Latin letter R, next to which the serial number and its denomination are indicated in accordance with the International System of Units (SI). For example, R12 5 kOhm is a five kilo-ohm resistor located in the circuit under number 12.

When manufacturing an element, a resistive layer is used, which can be film or volumetric. It is applied to a dielectric base and covered with a protective film on top.

Resistance value

Resistance is a fundamental quantity in electrical processes. Its meaning is invariably related to current and voltage. Their general dependence is described using Ohm's law: the current strength arising in a section of the circuit is directly proportional to the potential difference between the extreme points of this section and inversely proportional to its resistance. From this law the resistance is found using the following formula:

R = U / I, where:

- R is the resistance in the circuit section, Ohm.

- I is the current strength passing through this section, A.

- U is the potential difference at the nodes of a part of the circuit, V.

In fact, the resistance of an element is determined by its physical structure and is caused by the vibrations of atoms in the crystal lattice. Therefore, all materials are classified as conductors, semiconductors and dielectrics depending on their ability to conduct electricity.

Current is the directed movement of charge carriers. For it to occur, the substance must have free electrons. If an electric field is applied to such a physical body, then the charges it moves will begin to collide with inhomogeneities in the structure. These defects are formed due to various impurities, violation of lattice periodicity, and thermal fluctuations. By hitting them, the electron expends energy, which is converted into heat. As a result, the charge loses momentum, and the magnitude of the potential difference decreases.

But Ohm's law cannot be applied to all substances. In electrolytes, dielectrics and semiconductors, a linear relationship between the three quantities is not always observed. The resistance of such substances depends on the physical parameters of the conductor, namely its length and cross-sectional area, and it is sensitive to temperature changes.

This dependence is described using the formula R = p * l / S. That is, the resistance is directly proportional to the length and inversely proportional to the area of the conductor. The value p is called resistivity and is determined by the type of material. Its meaning is taken from the reference book.

Resistor impedance

Ohm's law applies to an ideal resistor that has no parasitic resistance. The total resistance (impedance) is determined based on the equivalent circuit. Accurate calculation of resistance to reduce voltage must be carried out using other formulas. The equivalent circuit of a resistor, in addition to active impedance, also contains capacitive and inductive reactance. The first leads to a slow accumulation of charge, which dissipates when the direction of the current changes. The larger the parasitic capacitance, the longer it takes to charge. Accordingly, the faster the current changes its direction, the lower its capacitance. The second is characterized by a magnetic field, whose appearance prevents the current from changing direction, therefore, the faster the current changes its movement, the greater the inductive reactance becomes.

Impedance is calculated using the formula : I = U/Z, where Z = (R2+(Xc-Xl)2)½. Where:

- R is the active value, R = p*l/s.

- Xc is a capacitive value, Xc = 1/w*C.

- Xl is an inductive quantity, Xl = w*C.

- w is the cyclic frequency, w = 2πƒ.

Knowing the total resistance of the resistor, you can more accurately calculate the voltage drop in it. But to measure parasitic components you will need to use highly specialized instruments. In conventional calculations, resistance is calculated taking into account only its active value, and parasitic values are taken as negligible.

Automatic transmission: advantages and principle of operation

Automatic gearboxes are becoming more and more common in vehicle designs. In principle, this trend does not cause much surprise, since people have always strived and will strive to automate processes. Of course, you can change gears by changing the speed of the engine shafts manually, but it is much more convenient when the operation occurs automatically. How is this possible? The secret lies in the design and operating principles of the automatic transmission, which we will discuss in more detail in today’s material.

History of appearance

An automatic gearbox or, as popularly known, an automatic transmission (automatic transmission) is an integral element of the transmission of many modern cars. The main purpose of this unit is to establish a balance between the spinning wheels and the running motor through fine selection of the gear ratio for each engine operating mode. The only difference between automatic transmissions and manual transmissions is that their operation is fully automated and does not require driver intervention.

The first more or less real automatic transmission appeared in the late 30s of the last century in Europe. Despite their novelty, innovative devices were too expensive and unreliable, so they could not fight the usual “mechanics”.

Everything changed when automotive engineers began to conduct experiments on introducing hydraulics and electronics into the design of automatic transmissions. As a result, the Chrysler organization created the first automatic transmission based on a torque converter and fluid coupling, which became a real breakthrough in the automotive industry.

The first prototypes of modern automatic transmissions appeared at the beginning of the 50th year of the 20th century, when two American engineers designed a box in which three parts worked at once:

Despite such a well-thought-out design of the automatic transmission, it began to be actively used only in the early 80s, that is, with the development of microprocessor technologies. Later, automatic transmissions began to be constantly modernized and today they can easily compete with “mechanics”.

Design and principle of operation of the machine

First of all, let's pay attention to the main types of automatic transmissions, of which there are only three:

So, the operating principle of an automatic transmission involves close interaction between mechanical, hydraulic and electronic devices. In the design of the box, these elements are represented by the following parts:

If we go into the details of how an automatic transmission works, it is worth noting the following stages of its operation:

Of course, the operating principle of the machine is more complex, but the order of its operation noted above fully reflects how it works. If we draw some parallels between an automatic transmission and a manual transmission, it is worth noting that the role of the clutch in the first is performed by the torque converter, and the role of the driver - the gear selector - is assigned to numerous control units of the box.

Reducing resistor automatic transmission Renault Espace 4

On Mazdas, Nissans and other cars, the automatic transmission usually has a “reducing resistor” located in the engine compartment, which affects the operation of the automatic transmission solenoids. So the question is: where does it fall on the spectrum?

Clutch slipping when changing gears. When I changed it, I stopped noticing any shocks at all, but there were noticeable impacts. On Mazdas, Nissans and other cars, the automatic transmission usually has a “reducing resistor” located in the engine compartment, which affects the operation of the automatic transmission solenoids. Who's at the conference now?