Toyota “classic”, durable and unpretentious - this is how the 3S-FE engine can be characterized. The engine of this modification was first installed on the 1986 Camry V20. Engine modernization in 1991, 1996, 1998 made major changes to the ignition system, camshafts, timing, intake manifold and connecting rod-piston group. The 3S-FE updates were not entirely successful, however, the engine remained in production for 17 years.

Technical characteristics of 3S-FE

The in-line 4-cylinder 16-valve internal combustion engine 3S-FE with a displacement of 2 liters (1998 cm3) is built on the basis of the 2S-FE. The designers equalized the piston stroke and cylinder diameter, making them 86 mm each. Engine performance increased to 115 hp. and 162 Nm. The power plant began to be equipped not only with a manual transmission, but also with an automatic transmission.

After the 1996 update, the unit received new characteristics:

| Engine | Power, hp at rpm | Torque, Nm at 4400 rpm |

| 3S-FE | 128/ 5400 | 178 |

| 3S-FE (2WD) | 140/ 6000 | 186 |

| 3S-FE (4WD) | 135/ 6000 | 181 |

| 3S FSE | 145/ 6000 | 196 |

Technical characteristics of the 3S-FE engine may vary depending on the modification and year of manufacture, but the differences do not exceed 5%.

The compression ratio of 3S-FE before 1996 was 9.5, after 1996 - 9.8. It is permissible to fill the engine with AI-92 and AI-95 gasoline. Fuel consumption when working with manual transmission:

- in a mixed cycle - 8.5 - 9.5 l;

- on the highway - 7 - 8 l;

- in the city - 11.5 - 13 l.

Oil consumption in a working 3S-FE engine ranges from 0.2 to 1 liter per 10,000 km. The manufacturer recommends changing the oil and filter every 10,000 km or once a year. Filling capacity - 3.9 l. Motor oils with a viscosity of 5W-30 and 10W-30 are suitable for filling.

Engine life is 300 thousand km according to the plant. However, with regular maintenance and proper operation, the 3S-FE can last over 500 thousand before overhaul. With good service, the unit will operate for more than 700 thousand km.

Operating fluids

The Toyota 3S-FE engine was developed according to old environmental requirements and can confidently consume 92 gasoline. Although the maximum performance will be provided on fuel with a 95 octane number. The modified version of the third series engine, which has a modified cylinder head and is designated 3S-GE, prefers 95 octane fuel.

The oil system and structural materials of the forged camshaft and cast iron block and other engine parts allow the use of semi-synthetic oil. Mineral-based motor oil was removed from assembly line fills back in the late 80s, so this type of lubricant is completely excluded. The use of synthetics will be justified only if there is little wear on the sealing collars.

But operational oil losses, which are caused not only by waste, but also by oil sweating from the cast iron block, make the use of synthetic oils economically unfeasible. When changing the oil, it should be taken into account that until 1996 the manufacturer recommended oils with a viscosity of 5w50, and after - 5W30

Design Features

The 3S-FE internal combustion engine is designed simply and thoughtfully. The cylinder blocks are made of cast iron, the cylinder heads are made of aluminum. There are two camshafts. There are no hydraulic compensators. The cylinder heads are poorly ventilated, so the engine is not suitable for forced loads. Fuel supply system is injection with electronic multipoint injection.

The disadvantages of the 3S-FE engine include the noisy operation of the exhaust system and noticeable rustling of the pulleys and rollers. After 200,000 km, a good oil appetite and high fuel consumption appear. The engine is piled up against the engine shield, making access for maintenance difficult.

Similar article Technical characteristics of the Mercedes OM 612 engine

A serious problem was discovered after the 1996 modernization. The designers reduced the mass of the piston group by 0.7 kg, leaving the crankshaft unchanged. To save money, the updated crank mechanism was not balanced, which led to vibration. Under its action, the bolt heads of one of the connecting rods are torn off. The part breaks loose and pierces the cylinder block. To prevent an accident during repair of the piston group, it is necessary to change the connecting rod bolts and tighten them strictly with the nominal torque.

Modifications to the unit in 1996 affected the ignition system. Mechanical distributors were replaced with dual coils that operate on 2 spark plugs. This doubled the load on the spark plugs and wiring.

Some 3S-FE models have an EGR gas recirculation system. An electric vacuum valve and a vacuum modulator-membrane are used for control. When the gas becomes rarefied, the EGR valve opens. After the EGR valve closes, the exhaust gases pass through the modulator filter. Every 2 years, it is advisable to blow out the filter with compressed air.

Improving the motor, the designers released a new version 3S-FSE. The unit was equipped with a D4 direct injection system and power was added, but overall the attempt was unsuccessful. The engine ran intermittently due to a broken fuel injection pump. Insufficient lubrication of the crankshaft and the accumulation of carbon deposits in the intake manifold forced owners to often visit the service center.

Maintenance

The mileage after which maintenance is required is 10 thousand km. During this period it is necessary to change the oil. However, when operating a vehicle in mountainous areas, where there is low temperature and in places with high dust content, regulated maintenance must be carried out twice as often.

This applies to all power plants, even those with mileage over 200 thousand km. The transmission of mechanical energy is carried out by means of a timing belt element. It must be replaced every 100 thousand km. mileage, regardless of operating conditions. Replacing the belt does not mean that its rupture will lead to valve deformation. The design is made in such a way that this malfunction cannot occur.

List of car models in which it was installed

The Toyota 3S-FE engine was produced in Japan at the Kamigo Plant, and also in the USA at Toyota Motor Manufacturing, Kentucky, Inc. at Georgetown from 1986 to 2003. 3S-FE was installed on Japanese cars of class D, E, and was also installed on minivans and SUVs with front-wheel drive and all-wheel drive. In total, more than a million cars were produced for the Japanese, European and American markets.

3S-FSE motors released after 1996 were installed on a few Corona Premio ST210, as well as Vista V50 and Nadia SXN10.

| Model Toyota | Drive unit | Years of manufacture |

| Avensis ST220 | 2WD | 1997 — 2003 |

| Caldina ST190, ST210 | 2/4WD | 1992 — 2002 |

| Camry V20, V30, V40 | 2/4WD | 1986 — 1998 |

| Carina ST170, ST190, ST215 | 2/4WD | 1987 — 2001 |

| Carina ED ST200 | 4WD | 1993 — 1998 |

| Celica ST160, ST180, ST200 | 2/4WD | 1986 — 1996 |

| Corona ST170, ST190, ST210 | 2/4WD | 1987 — 2001 |

| Corona Exiv ST200 | 2WD | 1989 — 1998 |

| Curren ST200 | 2WD | 1994 — 1999 |

| Ipsum/Picnic SXM10 | 2/4WD | 1996 — 2001 |

| Gaia SXM10 | 2/4WD | 1998 — 2002 |

| Nadia SXM10 | 2/4WD | 1998 — 2002 |

| Rav4 SXA10 | 2/4WD | 1996 — 2000 |

| Vista V55, Ardeo | 4WD | 1998 — 2002 |

Similar article Technical characteristics of the 3S GE BEAMS engine

Maintenance schedule

To ensure maximum service life, especially on machines manufactured after 1996, the manufacturer recommends that you follow the maintenance regulations, since major repairs are impossible for them. The table shows the frequency of replacement of consumables:

| Maintenance object | Time or mileage (whichever comes first) |

| Timing belt | replacement after 100,000 km |

| Battery | 1 year/20000 |

| Valve clearance | 2 years/20000 |

| Crankcase ventilation | 2 years/20000 |

| Belts that drive attachments | 2 years/20000 |

| Fuel line and tank cap | 2 years/40000 |

| Motor oil | 1 year/10000 |

| Oil filter | 1 year/10000 |

| Air filter | 1 – 2 years/40000 |

| Fuel filter | 4 years/40000 |

| Heating/Cooling Fittings and Hoses | 2 years/40000 |

| Coolant | 2 years/40000 |

| Oxygen sensor | 100000 |

| Spark plug | 1 – 2 years/20000 |

| Exhaust manifold | 1 year |

Each Toyota model has a manual containing a description of what oil and coolant to use.

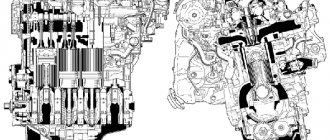

3S-FE engine design

The 3S-FE engine consists of a mechanical part and a set of systems: lubrication, cooling, injection, starting and charging. The 3S-FE device uses the simplest and most understandable mechanisms. Electronically, the 3S-FE engine contains an EFI multi-point injection system and an ECU control system.

Cooling system

The internal combustion engine is equipped with a forced cooling system. Antifreeze or antifreeze is used as a coolant. According to the regulations, the fluid is supposed to be changed after 40,000 km. The filling volume depends on the car model and ranges from 5.9 to 7.6 liters.

Coolant circulation is provided by a pump. It is located on the cylinder block and is driven by the timing belt. The electric fan directs the heated coolant to the radiator, where excess heat is released.

The engine has 2 coolant temperature sensors. One sends data to the ECU, the other to the dashboard. To quickly warm up the coolant in winter, a thermostat is built into the system, which closes a large circulation circle until the coolant is heated to 80℃.

Gas distribution mechanism

The 3S-FE engine has a timing system built according to the DOHC scheme with two cam-type camshafts. The shafts are connected to each other via gears. The intake camshaft is driven by a belt drive, and the exhaust camshaft is driven by a gear drive.

Due to the lack of hydraulic compensators, it is necessary to check the clearances in the valve drive after 20,000 km. Adjustment is carried out by selecting adjusting washers installed on disc pushers. The thickness of the washer varies from 2.5 to 3.3 mm, which allows you to choose analogues that are cheaper than the original.

The timing belt drives the pump and oil pump, experiencing severe overloads. A broken belt does not cause serious damage to the engine: the pistons and valves in the 3S-FE do not collide. According to the regulations, the belt should be changed after 100 thousand km. Drivers often do this on their own.

Injection system

The electronic fuel injection system consists of the fuel system, air supply and electronic control. Fuel is supplied to each injector under pressure calculated by the pressure regulator. After receiving a signal from the ECU, fuel is injected into the intake manifold. Excess fuel is returned to the tank through the return tube.

The amount of air supplied depends on the degree of opening of the throttle valve and the crankshaft speed. Air enters the upper part of the intake manifold and is distributed among the cylinders. Even if the throttle is closed, the air mixture will flow through the idle air system valve.

Lubrication system

The Toyota 3S-FE engine has a combined lubrication system. For rubbing parts, oil is supplied by a gear-type oil pump with internal teeth. In less loaded components, lubricant is sprayed through oil nozzles.

Similar article Engine for Niva Chevrolet VAZ 2123

Power supply and engine starting

The 3S-FE engine has a starter starting system. When the key is turned in the ignition switch, the electrical circuit is closed. The ECU polls the sensors and checks the health of the circuit. The fuel pump turns on.

On the next turn of the key, the battery supplies starting current to the traction relay. The relay creates a power of 1.0 - 1.2 kW, which spins the starter. The starter torque is transmitted to the crankshaft flywheel and spins the shaft until the engine accelerates to a stable speed.

The main power source for the engine is an 80A current generator.

Modifications

Engine series 3S, mass-produced Toyota unit. Over the 23 years that the engine was produced, the power plant was repeatedly redesigned and modified. The first 3S-FC models were produced with a carburetor, subsequent ones, such as the 3S-GTE, were already turbocharged and had a power of 260 hp.

Let's look at modifications of 3S series motors:

Engine 3S-FC (86-91 years of manufacture).

- The first power plant in the series, the engine is rare and was produced with a carburetor. The engine was used in the inexpensive Toyota Camry and Holden Apollo cars. The ratio of the total volume of the cylinder to the volume of the combustion chamber of the model is 9.8:1, the power of the unit is 111 hp.

Engine 3S FE (86 - 2000).

- The modification is equipped with an injector, a motor, the main engine of the series, since it was installed on most cars produced by the corporation at that time. The 3S FE model uses two ignition coils, the unit is regulated for the use of both 92 and 95 gasoline. The ratio of the total volume to the volume of the combustion chamber is 9.8:1, power varies from 115 to 130 hp. (affected by control electronics).

Toyota 3S FE engine:

Engine 3S FSE D4 (97-2003 model year).

- The modification is equipped with direct fuel injection (the first Toyota engine). The 3S FSE engine changes the intake valve timing because the corresponding mechanism (VVT-i) is installed. An intake manifold is used, on which the cross-section is adjusted at a right angle to the longitudinal axis of the channel. There is a recess in the pistons that gives the fuel the desired direction. In addition, other sprayers, spark plugs, and a channel flow regulator with electronic adjustment are installed. The engine uses a special valve that directs the exhaust to afterburning. The ratio of the total volume to the volume of the combustion chamber is 9.8:1, the power of the power plant is 150 hp.

Engine 3S FSE D4:

Description of marking

The 3S-FE engine marking according to the Japanese system looks like: 3S-FE DOHC 16V 2.0, where:

- “3” denotes a new design in the motor line;

- “S” - Toyota engine series;

- “F” - engine of the power range from 2.0 to 2.2 liters with 4 valves per cylinder;

- “E” - presence of an EFI system;

- “DOHC” - gas distribution mechanism with two camshafts;

- “16V” - V-shaped 16-valve engine;

- “2.0”—engine size.

Tuning

Today, there are several fairly effective 3s fe engine tuning programs that allow you to increase power to 200 horsepower or more.

You just need to remember that such an increase in the power of the power unit should be carried out exclusively by a specialist, which will ensure the preservation of the engine’s service life.

- The easiest way to increase the power of the 3S FE engine is to install a turbocharger, which allows you to increase the power of the power unit to 200 horsepower. In this case, it is also necessary to replace the crankshaft, reconfigure the injection system and install a new fuel pump. Work is also being carried out to reconfigure the engine control unit.

- A relatively simple option for tuning a 3S engine is to install a new exhaust system and replace some of the attachments. Such work will allow the car owner to get an additional 20-30 horsepower. In this case, there is no need to open the engine and carry out any complex repair work.

Engine fault overview

Despite the thoughtfulness and unpretentiousness of the 3S-FE engine, drivers face some problems:

- increased fuel consumption. Occurs due to improper operation of the throttle valve or one of the sensors that transmit incorrect information to the ECU. Contaminated injectors also interfere with the formation of a normal mixture. Carbon deposits on the pistons lead to excessive fuel consumption due to changes in the volume of the combustion chamber and loss of power;

- increased appetite for butter. Often found in cars with mileage over 200,000 km. Carbon deposits on the pistons indicate severe burns through compression and oil control piston rings and leaking valve seals. The malfunction may also be in the sensors: lambda probe, intake air temperature sensor or map sensor;

- Long cold start. The problem is due to a breakdown of the fuel injectors or temperature sensor;

- Unstable engine operation, loss of power. The reason is a breakdown of the EGR valve or engine oil getting into the spark plug wells: the ignition occurs with misfires, and the engine stalls at idle;

- motor vibrations. The problem occurs when the side cushions wear out or there is a loss of pressure in one of the cylinders.

Engine problems can be corrected by replacing or cleaning the elements. The 3S-FE design allows for simple repairs even in garage conditions.

https://www.youtube.com/watch?v=KcCTjpVy-sc

Main breakdowns and ways to fix them

Typical malfunctions for the 3S-FE engine, without taking into account the sensors and regulators of the on-board ECU system that can be attached to it, are:

| Malfunction | Cause | Elimination |

| Speed misadjustment XX | coke on the walls of the intake manifold, reducing combustion chamber volumes dirt on the throttle valve | cleaning the valve and manifold |

| fuel pump failure | fuel pump repair | |

| clogged air filter | replacing the air filter | |

| Floating speed | EGR valve failure | cleaning or replacing the valve |

| Progressive Vibrations | problem in the engine airbag one cylinder does not work | airbag inspection, engine diagnostics |

| Increased fuel consumption | the ignition is broken; XX valve adjustment is broken ; dirt in injectors | adjusting the ignition and idle air valve, cleaning the injectors |

Engine repair

Where are the faults?

No specific diseases were noted with GE, except for the possibility of bending the valves when the timing belt breaks. Although the piston heads of the entire family, except for the latest modification, are equipped with recesses, in the event of a break, the valves of other generations also bend.

The name “Beams” is precisely consonant with the last sound made by the engine in this situation. Such cases are not observed only in generations under 3 gen, and only if you are lucky.

Attention: premature destruction of the toothed belt is most often caused by drips of antifreeze and liquid lubricant on the rubber, which soften the material. In this case, the cord remains intact, and the drive pulley simply cuts off several teeth on the inner surface of the product.