Engine tuning

The increase in power is of particular interest to owners of cars with a small engine capacity.

For NZ series motors it is also possible to increase power by installing a centrifugal compressor. This system is an attachment, and its use does not require registration with the traffic police. There are various modifications of charger kits that can significantly increase engine performance. They can have a disconnectable clutch or be fully integrated into the operation of the internal combustion engine. Although this method does not reach full boost, it allows you to increase power to 145 hp. With.

Review of faults and methods for repairing them

Toyota 2NZ-FE engine

Due to its design features, the 1NZ FE engine is guaranteed to bend the valve during a timing chain break. However, other faults are more relevant to the user:

| Uncontrolled engine oil consumption | 1) worn valve stem seals 2) coked or worn-out rings | 1) replacing caps 2) replacing rings |

| Third party sounds | 1) chain stretch 2) wear of liners 3) carbon deposits on the valves 4) development of rollers/pushers | 1) replacing the chain with a kit 2) replacement of liners 3) decarbonization with special detergents 4) replacement of rollers, pushers |

| Floating speed | 1) IAC breakdown 2) damper clogged | 1) replacing the XX regulator 2) cleaning the throttle |

Repair 1NZ FE

Engine tuning options

We understand VAZ engines

It is theoretically possible to boost the 1NZ FE engine in seven stages:

- exhaust modernization - forward flow, “spider” and ECU correction to produce 145 hp. With. maximum;

- modification of the fuel system - the use of high-performance injectors and Apexi Power FC “brains” to provide 150 hp. With.;

- supercharging - turbine plus intercooling, installation of a high-performance brake system, power increases to 180 - 200 hp. With.;

- supercharger - usually Supercharger

Tuning 1NZ-FE

Thus, the 1NZ FE engine is distinguished by an aluminum block and a timing chain drive according to the DOHC 16V scheme. It is used in almost the entire model range of the Toyota manufacturer, which came off the assembly line from 1997 to 2005, and in some modern cars.

Features of the mechanical part of this type of internal combustion engine

1mz fe

Due to the fact that the working elements and lubrication and cooling systems of 1nz fe engines have an original design, car owners are interested in what characteristics the 1NZFE engine has.

Engines of this type are located in the transverse plane in passenger cars with front-wheel drive.

The base 1NZ FXE engine has a high compression ratio of 10.5 and a power of 109 horsepower; the cylinder capacity is one and a half liters.

The NZ engine is a 4-cylinder power unit, the cylinders in it are located straight. The cylinder block and head are made of aluminum alloys, the liners are made with thin cast-iron walls, and the cooling is open. The sleeves are connected to the block as firmly as possible due to irregularities on their surface.

Fuel is injected sequentially according to the SFI system. Each injector is equipped with a separate wire that receives a signal from the electronic power unit control unit, which controls the opening and closing timing.

The 1NZ FE engine has an ignition system equipped with a separate coil, each cylinder has a built-in switch. Spark plugs are Denso K16R-U11 and NGK BKR5EYA11.

The 1nz fe engine has a design that does not require major overhauls.

The Toyota 1nz engine is used in the Allion-Premio, AurisJap, Corolla, CorollaRumion, etc.

Versatile and reliable

Toyota 1gz-fe engine

In the event of a serious breakdown, repairs are not carried out, but the 1NZ-FE engine is simply replaced. But as practice shows, many cars are scrapped before this engine fails. It is because of its reliability that this power unit is installed on 17 models of Toyota cars. It is found even on European and American cars. This says a lot, because the Japanese are famous for the quality of their cars, and this engine is proof of that. Some car enthusiasts boost the power unit in order to obtain additional power. This approach also makes sense, because many people lack 109 “horses”.

List of car models in which it was installed

The naturally aspirated in-line four-cylinder engine 1NZ FE, operating on the classic Otto cycle, was installed on Toyota modifications:

- Corolla Fielder/Axio – station wagon for Russia and 11th generation sedan;

- Ractis – subcompact van with a glass roof;

- Succeed – right-hand drive minivan with all-wheel/front-wheel drive;

- Probox – family minivan;

- Will – a youth car with an original design;

- Sienta – minivan with sliding doors;

- Allion – a sedan with a sporty exterior;

- Premio – a sedan for the older generation;

- Fun Cargo – a compact van with an original exterior;

- Auris – family hatchback, new generation of Corolla;

- Platz – classic sedan;

- Porte – subcompact van with doors of different types of opening;

- Raum – subcompact van with automatic transmission;

- Vios – sedan;

- bB – subcompact van in English style;

- Yaris/Echo is a classic sedan.

Toyota Fun Cargo

Toyota 1NZ engine characteristics

| Production | Kamigo Plant |

| Engine make | Toyota 1NZ |

| Years of manufacture | 1997-present day |

| Cylinder block material | aluminum |

| Supply system | injector |

| Type | in-line |

| Number of cylinders | 4 |

| Valves per cylinder | 4 |

| Piston stroke, mm | 84.7 |

| Cylinder diameter, mm | 75 |

| Compression ratio | 10.5 13 13.4 |

| Engine capacity, cc | 1497 |

| Engine power, hp/rpm | 74/4800 76/5000 109/6000 |

| Torque, Nm/rpm | 111/3600 115/4000 141/4200 |

| Fuel | 95 |

| Environmental standards | Euro 5 |

| Engine weight, kg | 112 |

| Fuel consumption, l/100 km (for Premio) - city - highway - mixed. | 13.0 6.0 9.5 |

| Oil consumption, g/1000 km | up to 1000 |

| Engine oil | 5W-30 10W-30 |

| How much oil is in the engine | 3.7 |

| Oil change carried out, km | 10000 (better 5000) |

| Engine operating temperature, degrees. | ~90 |

| Engine life, thousand km - according to the plant - in practice | n.d. ~200 |

| Tuning - potential - without loss of resource | 200+ n.a. |

| The engine was installed | Toyota CorollaToyota Yaris Toyota Premio Toyota Allion Toyota Vios Toyota bB Toyota Belta Toyota Raum Toyota Porte Toyota Platz Toyota Ist Toyota Auris Toyota Fun Cargo Toyota Sienta Toyota WiLL VS Toyota WiLL VC Toyota Probox Toyota Ractis Geely CK Geely MK Great Wall C10 Scion xA Scion xB |

Measures to eliminate identified defects

To stabilize the engine speed at idle, you need to thoroughly clean and rinse the throttle body and idle air valve, replace the idle speed controller, air sensor, etc.

An increase in engine oil consumption occurs due to long runs of 150,000 km. In this case, the engine needs to replace the obstructed rings and valve stem seals.

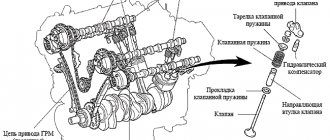

When replacing the single row timing chain and alternator belt, all noise effects disappear. When installing the chain, it must be properly tightened. When changing the chain, it is also necessary to replace the VVT sprocket, tensioner and guide. The chain is lubricated with machine lubricant. To make the motor make less noise, the design provides for the installation of a special tensioner, shoe and chain guide.

To eliminate vibrations of the power unit, you should strengthen the front engine mount, clean the injectors, replace the fuel filter, oil pressure sensor, and rear crankshaft seal.

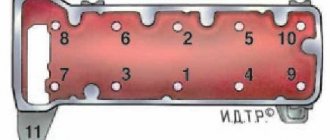

The tightening torque of the bolts when securing the cylinder head must be equal to the recommended values specified in the technical documentation. All bolts must be tightened strictly according to the instructions. After carrying out these activities, the motor will be firmly fixed.

To the question of what kind of oil to pour, the answer is unequivocal - it is necessary to fill only high-quality motor lubricant into the tank of the power unit in accordance with the manufacturer’s recommendations located in the accompanying documentation of the car. It is recommended to fill the 1nzfe engine with 0W20 engine oil.

Car owners often ask what spark plugs are in the ignition system of 1nz fe power units. According to the vehicle documentation, the 1NZFE engine is equipped with an ignition system that uses spark plugs made of iridium.

Major repairs of the 1NZ engine are not carried out, since the cylinder block installed in it is not repairable after a mileage of over 200 thousand kilometers. Judging by the reviews of car owners, a worn-out engine should not be repaired, but completely replaced with a new copy, because replacing components and components that have failed will cost more than the cost of a new power unit.

At the request of the car owner, it is possible to tune the 1NZ engine; for this it is proposed to use standard tuning kits available for free sale.

Description of common problems that a 1nzfe engine may have

Toyota's new generation power units, NZ are the most successful. Common problems with 1NZFXE motors:

- Low and unstable floating idle speed.

- Increased lubricant consumption.

- The warning light on the dashboard lights up, indicating low or high oil pressure in the lubrication system in the power unit.

- Crackling noisy VVti valve and knocking in 1nz after cold start.

- Increased requirements for quality and cleanliness in the lubrication system.

- The cylinder head (cylinder head) drive chain has a short service life.

- Vibrating motor1nz fe.

Despite the listed disadvantages, the 1nzfe engine installed in a compact Toyota car is a successful representative of modern Japanese power units.

Design Features

The NZ series turned out to be long-lasting:

- 2000 – 2005 – 105 l. s., 138 Nm, assigned index NZE124;

- 2005 – 2007 – 109 liters. s., 141 Nm, NCP90 index;

- 2007 – 2013 – 110 l. s., 140 Nm, index NZT260;

- 2013 – … – 109 liters. s., 136 Nm, index NZT.

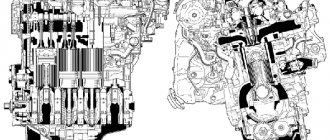

The 1NZ FE naturally aspirated in-line petrol engine includes design features of the ZZ/AZ family and fresh developments from Toyota designers:

- cast iron liners are poured directly into the aluminum block, so overhaul of the cylinders is impossible;

- the cast crankcase serves as an oil pan and ensures block rigidity;

- the axis of the forged steel crankshaft is offset relative to the cylinders by 12 mm;

- lightweight piston skirt with polymer coating, press-fit pins;

- a feature of the intake camshaft is the presence of a VVTi clutch for adjusting valve timing;

- the cylinder head is equipped with standard mounting holes for injectors and valve seats;

- the oil pump is located in the crankcase and has a separate drive from the crankshaft;

- heated throttle valve, “cold” thermostat 84 degrees, mechanical type;

- the pump is driven by a common belt, like all other attachments;

- Double-shaft timing belt, DOHC 16V type, driven by a single-row chain on the exhaust camshaft;

- the manifolds have changed location - inlet at the front, exhaust at the rear, so do-it-yourself boosting was made easier by the designers from the very beginning;

- there is no return line in the fuel system, fine-dispersion multipoint injectors;

- mechanical throttle valve, DIS-4 ignition with separate coils for each spark plug.

Crankshaft axis offset

Gas distribution mechanism

Lubrication scheme

Design features of the 2NZ FE motor

When creating this engine, the manufacturer tried to make its design as light as possible. Light alloy metals were used to make the cylinder block, and the cooling jacket of the power unit has an open design. To ensure greater compactness, the cylinder block itself is made thin-walled and its thickness between adjacent cylinders does not exceed a distance of 8 mm. This design of the engine is considered non-repairable and must be completely replaced after its service life has expired.

- The cooling system for the 2NZ FE engine is liquid type and has a closed circuit. For greater efficiency, forced circulation is used, which shows good results even in difficult working conditions;

- The intake manifold is made of plastic and has elongated pipes to facilitate engine movement. The exhaust manifold has a ball joint and also uses long pipes;

- The timing drive has a single-row chain design with a pitch of 8 mm, which is equipped with a chain tensioner and damper. Its lubrication is carried out by an oil nozzle, and the chain itself is made of particularly durable materials;

- The lubrication system operates according to a full-flow cleaning scheme, and the oil is supplied to the main components and parts under pressure. The oil pump is of the trochoid type, and the oil filter is installed at the bottom next to the sump;

- The ignition system has a DIS-4 classification, which provides its own ignition coil for each cylinder. This design ensures high precision spark supply. Spark plugs on 2NZ FE can be installed with simple or iridium designs.

Malfunctions of 2NZ FE motors

There are both certain advantages and disadvantages in the operation of the 2NZ FE engine. A car equipped with such a motor will not cause problems for a long time. With proper operation, you can drive at least 200 thousand km. without noticeable problems with the engine. The design of the power plant is reliable enough for city driving or long-distance travel.

However, such characteristics are not without their drawbacks. The small size of the engine and its optimization by the manufacturer make it almost impossible to carry out overhauls, and even more so you should not do it yourself. The small distance between the pistons will not allow boring. The thin timing chain also does not cause delight, although it is capable of working out its entire intended resource.

Advantages and disadvantages

The main disadvantages of the engine are its gluttony and short service life. It is impossible to overhaul the 1NZ FE engine, since the liners poured into the cylinder block are irreplaceable. Over two decades, much has improved in engines, but maintainability has remained at the same level.

Advantages: small size and weight. It does not need to be repaired with good daily care. All that remains is to change technical fluids in a timely manner. Many motorists call it hassle-free. It is installed on 17 different light-duty Toyota cars, as well as some American and European cars.

Maintenance schedule 1NZ FE 1.5 l108 l. With.

The factory manual indicates maintenance periods and replacement operations for consumables that the 1NZ FE engine has in its design:

- the manufacturer provides for replacement of the roller-type timing chain after 120 - 150 thousand mileage;

- the manufacturer recommends changing oil that has lost its properties after 7,500 km, and antifreeze after 20,000 km;

- It is recommended to change the air and fuel filters after 10,000 and 30,000 mileage, respectively;

- adjustment of thermal clearances of engine valves is carried out once every 2 years (mileage 30,000 km);

- the service life of spark plugs in the DIS-2 system is 30,000 km, when using iridium modifications 60,000 km;

- the exhaust tubular manifold begins to burn out after 50 - 70 thousand mileage.

Replacing the timing chain

Service

If the unit is handled correctly, it can operate for even 500 thousand km. To do this, you need to change the oil and filters on time. On time - this is after 10,000 km. The valves are adjusted every 20,000 km. 150,000 km is the time to replace the timing chain. This needs to be done correctly, so the story needs to be more detailed. The work plan for removing the chain is something like this:

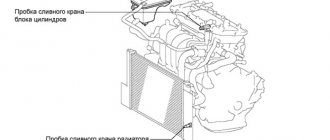

- antifreeze and oil are drained;

- belts of the generator and other attachments are removed;

- the pump pumping antifreeze, the cylinder head and ignition coils are removed;

- disconnect the hoses;

- remove the chain cover and tensioner;

- remove the damper and the chain itself.

All removed parts are wiped and carefully inspected.

To install the chain, perform the operations in reverse order. The tightening torque of the damper bolts is 9 N.m. A layer of fresh sealant is applied under the cover and O-rings are installed. After all operations are completed, oil and coolant are poured in and the engine is started for a while. With the engine running, all connections are inspected for leaks.

Antifreeze is poured into the cooling radiator, which needs to be changed once every 1.5-2 years. Liquids that require periodic replacement include oil. It is advisable to fill in the varieties recommended by the plant. This is not possible everywhere and is not always possible. The most popular types of oils from our stores: Elf, Motul 5w30. Sellers can recommend other types of oils. It is recommended to change the air filter every 20 thousand km, but you can do this more often if you drive a lot on dusty roads.