The reader will learn how to measure engine oil pressure. What are the reasons for its drop and how can the oil pressure be adjusted. The article will provide instructions on maintaining the correct balance and caring for the engine of a Toyota car.

The oil pressure in the engine should always be normal. If it is lower, the engine simply will not start. And the increase in pressure will cause the seals to squeeze out, through which the oil will leak out of the Toyota Corolla.

What is measured and what should it be

Oil pressure is measured with a special pressure gauge in Toyota Corolla vehicle engines. It can also be determined by external signs.

Without a pressure gauge, to determine the oil pressure in the engine, the car owner needs:

- Open the Toyota hood.

- Determine the lubricant level in the engine using a dipstick.

- Remove the wires from the ignition coils and the pressure sensor installed by the manufacturer.

- Use an electric starter to rotate the crankshaft.

- Watch how oil will pour out of the hole from which the sensor is removed, or vice versa if it is missing.

If there is a strong jet during the procedure, then the sensor has broken down. If there is not even a drop of liquid at all, then the oil does not enter the engine. All these problems are solved at the service center.

However, if the car owner has a pressure gauge, then you can measure the pressure like this:

- Warm up the engine to operating temperature.

- Then stop the engine and remove the key from the ignition.

- Open the hood and unscrew the oil pressure sensor.

- Install the adapter into the hole where the sensor was located. To which to attach the pressure gauge.

- Start the engine and check how much bar the pressure gauge needle shows at idle.

- Increase the shaft speed to 5400 rpm.

- Check the oil pressure in the Toyota Corolla vehicle.

Attention! At 3000 rpm, the pressure gauge needle should be between 1.5 kgf/cm² to 5.6 kgf/cm². This is the force of movement of the lubricating fluid in engines with a volume of 1.3 to 2.0 liters.

The optimal value is influenced by the viscosity of the poured oil. The latter must be original and, according to technical documents, correspond to the W50 or W20 brand. If the latter is filled, then the value on the pressure gauge will be within 1.5 kgf/cm², and if W50 liquid is filled, the needle will rise to 5.6 kgf/cm². This happens because W50 is more viscous compared to W20.

At idle, the optimal value for Toyota Corolla engines with E150 and E 180 bodies is as follows:

- 30 kPa for a 1.3-liter engine and a manual transmission at 600 - 800 rpm or CVT;

- 25 kPa for an engine with a volume of 1.6 to 2.0 liters and a manual transmission at 600 - 800 rpm or a CVT.

Toyota Corolla E150 (2010+). Insufficient oil pressure (low oil pressure indicator light is on)

| Add oil | ||

| Oil filter is faulty | Replace the filter with a known good one. | Replace the faulty oil filter |

| The bolt securing the auxiliary drive pulley is loose | Check bolt tightness | Tighten the bolt to the specified torque |

| Clogged oil receiver mesh | Inspection | Clear the mesh |

| Skewed, clogged oil pump pressure relief valve or weakened valve spring | Inspection when disassembling the oil pump | Clean or replace the faulty relief valve. Replace the pump |

| Worn oil pump gears | Determined by measuring parts after disassembling the oil pump (at a service station) | Replace the oil pump |

| Excessive clearance between bearing shells and crankshaft journals | Determined by measuring parts after disassembling the oil pump (at a service station) | Replace worn liners. If necessary, replace or repair the crankshaft |

| Insufficient oil pressure sensor is faulty | We unscrew the low oil pressure sensor from the hole in the cylinder head and install a known-good sensor in its place. If the warning light goes out while the engine is running, the inverted sensor is faulty | Replace the faulty low oil pressure sensor |

Causes of drop in oil pressure

There is a light on the instrument panel that indicates emergency oil pressure in the engine. When it lights up, it is a clear sign of a problem. We'll tell you what to do if the oil pressure light comes on and how to fix the problem.

The oil check light can come on for two different reasons: either low oil pressure or low oil level. But what exactly does the oil light on the dashboard mean, only the operating instructions will help you find out. It will help us that, as a rule, budget cars do not have a low oil level indicator, but only a low oil pressure indicator.

Insufficient oil pressure

If the oil light comes on, this means insufficient oil pressure in the engine. As a rule, it lights up only for a few seconds and does not pose a great threat to the engine. For example, it can light up when the car rolls heavily during a turn or during a cold start in winter.

If the low oil pressure light comes on due to a low oil level, then this level, as a rule, is already critically low. First of all, when the oil pressure light comes on, check for the presence of engine oil. If the oil level is below normal, then this is the reason for this lamp to light up. This problem can be solved simply - you need to add oil to the required level. If the light goes out, we rejoice, and do not forget to add oil on time, otherwise this could result in serious problems.

If the oil pressure light is on, but the oil level on the dipstick is fine, then another reason why the indicator could light up is a failed oil pump. It does not do its job of ensuring sufficient oil circulation in the engine lubrication system.

In any case, if the oil pressure or low oil level light comes on, the car must be stopped immediately by pulling to the side of the road or to a safer place and turning off. Why do you need to stop right away? Because if the oil in the engine has depleted significantly, then the engine may stop and break down, with the prospect of very expensive repairs. Don't forget that oil is very important to keep your engine running. Without oil, the engine will fail very quickly - sometimes in just a few minutes of operation.

This situation also occurs when the engine oil is changed to new one. After the first start, the oil pressure light may come on. If the oil is of good quality, it should go out within 10-20 seconds. If it does not go out, the reason is a defective or non-functioning oil filter. It needs to be replaced with a new quality one.

Oil pressure sensor malfunction

The oil pressure at idle speed (at approximately 800 - 900 rpm) should not be less than 0.5 kgf/cm2. Sensors for measuring emergency oil pressure come with different response ranges: from 0.4 to 0.8 kgf/cm2. If a car is equipped with a sensor with a response value of 0.7 kgf/cm2, then even at 0.6 kgf/cm2 it will turn on a warning lamp, signaling a kind of emergency oil pressure in the engine. To understand whether the oil pressure sensor is to blame for the light coming on or not, you need to increase the crankshaft speed to 1000 rpm at idle. If the light goes out, then the oil pressure in the engine is normal. If not, then you need to contact specialists who will measure the oil pressure with a pressure gauge, connecting it instead of the sensor. Cleaning the sensor helps prevent false alarms. You need to unscrew it and thoroughly clean all the oil channels, because the cause of false alarms of the sensor may be due to blockages.

If the oil level is normal and the sensor is working

First of all, you need to check the oil dipstick and make sure that the oil level has not increased since the last check? Does the dipstick smell like gasoline? It is possible that gasoline or antifreeze is getting into the engine. It’s easy to check the presence of gasoline in the oil; you need to dip the dipstick in water and see if gasoline stains remain. If yes, then you need to contact a car service; the engine may need to be repaired. If there is a malfunction in the engine, which is caused by the oil pressure light coming on, it is easy to notice. Engine malfunctions are accompanied by loss of power, increased fuel consumption, and black or blue smoke coming out of the exhaust pipe. If the oil level is normal, then there is no need to worry about a prolonged indication of low oil pressure, for example during a cold start. In winter, at low temperatures, this is an absolutely normal effect. After parking overnight, the oil drains from all lines and thickens. The pump needs a certain time to fill the lines and create the necessary pressure. Oil reaches the main and connecting rod journals earlier than the pressure sensor, so wear of engine parts is eliminated. If the oil pressure light does not go out for about 3 seconds, it is not dangerous.

What you can do yourself

Measuring engine oil pressure The problem of low oil pressure is greatly complicated by the relationship between lubricant consumption and level drop with the overall pressure in the system. In this case, a number of malfunctions can be eliminated independently.

If leaks are detected, the problem is quite easy to localize and solve. For example, oil leakage from under the oil filter can be eliminated by tightening or replacing it. The problem with the oil pressure sensor, through which lubricant flows, is solved in a similar way. The sensor is tightened or simply replaced with a new one. As for seal leaks, in this case you will need time, tools and skills. In this case, you can replace the front or rear crankshaft oil seal with your own hands in your garage with an inspection hole.

Oil leaks from under the valve cover or in the pan area can be eliminated by tightening fasteners, replacing rubber gaskets, and using special engine sealants. Violation of the geometry of the connecting planes or damage to the valve cover/pan will indicate the need to replace such parts.

If the coolant gets into the engine oil, then you can remove the cylinder head yourself and replace the head gasket, while following all the recommendations regarding the removal and subsequent re-covering of the cylinder head. An additional check of the mating planes will indicate whether the cylinder head needs to be ground. If cracks are found in the cylinder block or head, repairs are also possible. As for the oil pump, if this element wears out, it is better to immediately replace it with a new one. It is also not recommended to clean the oil receiver, that is, the part is completely changed. In the case where the problem in the lubrication system is not so obvious, and you have to repair the car yourself, then at the very beginning you should measure the oil pressure in the engine. To solve the problem, as well as taking into account an accurate understanding of where the oil pressure in the engine is measured and how it is done, additional equipment must be prepared in advance. Note that there is a ready-made device for measuring engine oil pressure available for free sale.

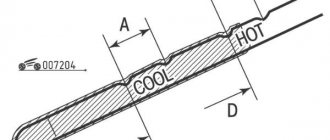

As an option, a universal oil pressure gauge will “Measure”. This device is quite affordable and comes with everything you need. You can also make a similar device with your own hands. To do this, you will need a suitable oil-resistant hose, pressure gauge and adapters.

To measure, a ready-made or home-made device is connected instead of an oil pressure sensor, after which the pressure readings on the pressure gauge are assessed. Please note that ordinary hoses cannot be used for self-production. The fact is that oil quickly corrodes rubber, after which the detached parts can get into the oil system.

Results

The pressure in the lubrication system can drop for many reasons: - quality of the oil or loss of its properties; - leaks of oil seals, gaskets, seals; -oil “presses” out of the engine (pressure increases due to malfunctions of the crankcase ventilation system); - oil pump malfunctions, other breakdowns; -the power unit may be severely worn out, etc.

In some cases, drivers resort to using an additive to increase engine oil pressure. For example, XADO revitalizant. According to manufacturers, such an anti-smoke additive with revitalizant reduces oil consumption, allows the lubricant to maintain the required viscosity when heated to high temperatures, restores damaged crankshaft journals and liners, etc.

As practice shows, additives cannot be considered an effective solution to the problem of low pressure, but as a temporary measure for old worn-out engines, this method may be suitable. I would also like to draw your attention to the fact that the blinking oil pressure light does not always indicate problems with the internal combustion engine and its systems. It's rare, but it does happen that electrical problems arise. For this reason, the possibility of damage to electrical components, contacts, pressure sensor or the wiring itself should not be ruled out.

Finally, we would like to add that using only the recommended oil helps to avoid many problems with the oil system and engine. It is also necessary to select a lubricant taking into account individual operating conditions. The correct selection of viscosity index for the season (summer or winter oil) deserves no less attention.

Engine oil and filters must be changed correctly and done strictly according to regulations, since an increase in the service interval leads to severe contamination of the lubrication system. In this case, decomposition products and other deposits actively settle on the surfaces of parts and channel walls, clogging filters and the oil receiver mesh. Under such conditions, the oil pump may not provide the required pressure, causing oil starvation and significantly increasing engine wear.

content .. 35 36 37 38 ..

Causes of low or high blood pressure and their solutions

The following are the causes of low blood pressure and how to eliminate them:

- non-original lubricating fluid. Changing the technical parameters of the oil leads to an increase or decrease in pressure;

- low fluid level. Top up to the required level;

- The oil pump is faulty or the bearings are worn out. Replace the pump and bearings;

- dirty fuel. You will have to change the lubricant and no longer refuel at the station where the bad fuel was filled;

- The oil filter is not tightly connected to the system. Check and fix. Change the seal;

- the motor overheats. Fix the cooling system malfunction.

Causes of high blood pressure:

- The filter device is clogged. Remove and wash the filter, or install a new one;

- low oil viscosity. Change the lubricant to the original one, or refer to the technical documents to find out which oil is suitable. In this case, you should also check the engine and clean the turbo filter;

- accumulation of sediment in pipes. Eliminate the problem by flushing the motor.

The car owner cannot fix many of these faults with his own hands, without special skills. Therefore, when the first reasons for an increase or decrease in pressure appear, the car should be taken to a service center to check and replace faulty elements.

Checking the serviceability of the sensor with a light bulb

You can also check the electronic oil pressure sensor using a 12 V light bulb instead of a tester. To carry out such tests, you will need a charger (or battery) and a compressor (preferably with a pressure gauge). Diagnostics are carried out in the following sequence:

- Wires of sufficient length are soldered to each contact of the light bulb (0.5 - 1 will be enough).

- One end of the wire is connected to the output contact of the DDM.

- The “negative” terminal of the charger (or battery) is connected to the sensor body.

- The second wire from the lamp is connected to the “positive” terminal of the charger or battery. If the sensor is fully operational, after applying voltage from the charger (or connecting all elements of the circuit in the case of a battery), the light should light up. If it does not light up, the sensor is faulty. If it lights up, check further.

- The circuit includes a pump or compressor to pump approximately 0.5 atmospheres of pressure onto the sensitive part of the oil pressure sensor. The value may vary, it depends on the type of device and what operating pressure it is designed for. But more often it is precisely the floor of the atmosphere.

When the specified pressure is reached, the light should turn off, since in a working sensor the electrical circuit is broken. If this does not happen, the sensor must be replaced.