In this article we will look at a topic that can be useful to everyone. Whether it's because you have a flat tire or you want to replace your brake pads, knowing where the jack is on your Toyota RAV4 is important. Obviously, without a jack, you won't be able to lift your car and therefore change a wheel or access components behind it, such as brake pads. To achieve this, we will first explain the different types of jacks, then where the jack is located on a Toyota RAV4, and finally how to use a jack on your vehicle.

Jack and standard lifting points

Hello, I see there is no information anywhere: is it possible to lift a car with a rolling jack by installing the support of the rolling jack under the seats of the standard jack on a 4th generation RAV4?

I know that you need to lift it using a special jack. seats in front and behind the car. (On previous generations it was possible to lift it using the levers.) But on my front, the engine protection covers this place. At the tire shop they lifted it with a rolling jack and jammed the threshold. I took the standard jack and installed it under the threshold as stated in the instructions and saw that there was a gap between the rib on which the rolling jack was placed and the recess of the standard jack!

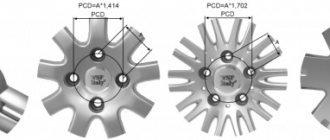

That is, the jack in this place does not rest against the rib, but above (in the photo, the left horizontal platform (the left part of the cutout on the top of the jack) rests against the floor of the car). Maybe that's why our ribs bend in these places? Moreover, when lifting a rolling jack, it does not lift the car strictly vertically, but as if “pulling” the car towards itself and thereby bends the rib on which it rests. How do you lift the car? Upd from 03/27/2019 I bought a support. I chose a larger and higher one - diameter 105 mm. I applied it to the threshold and realized that if you put it on the inside of the rib (from the rib towards the center of the car), then the support is too large. I cut a groove 25 mm deep in the support. I attached it to the regular place - everything is fine. There is a gap between the rib and the support - the rib will not bend when lifting. But I tapped my finger on the threshold and realized that on the inside of the edge the metal is thicker (judging by the sound), and on the outside there is thin metal. Therefore, the standard jack has contact only on the inside of the threshold from the rib. Now I’m thinking of cutting off the rubber on one side of the groove to reduce the height of the support in this place and placing the jack cup offset so that the center of the cup is on the inside of the threshold. Or buy a support with a smaller diameter so that you can place it directly in the required place. This is the support

Update dated 03/30/2019. I tried the support. Did not like. If you place the center of the jack cup under the rib, then the support presses on the outer and inner parts of the threshold. The outer part of the threshold is soft. You can move the jack cup, but then the support seems to break. Conclusion: The cut must be made smaller in height in order to lift the edge of the threshold or a support with a smaller diameter. I ended up buying a smaller support with a diameter of 65mm. I only place it on the inside of the threshold. Everything is ok, only the height of the jack is not enough (the jack can lift up to 330 mm). You will have to put a thick board under the jack.

Lifting a car with a jack

Lift the car with a jack as follows:

– place the car on a flat, horizontal surface with a hard surface;

– tighten the parking brake and engage 1st gear on vehicles with a manual transmission or set the selector lever to position “P” on vehicles with an automatic transmission;

– on the side opposite to the one being lifted, block the wheel with stops;

Rice. 1.37. Jack installation points when lifting a car

– remove the jack from under the right front seat and install it so that its cushion is under one of the following points (Fig. 1.37).

1. When replacing the front wheel, use the rear mounting of the front suspension arm.

2. When replacing the rear wheel, use the rear suspension arm;

Make sure the jack is installed correctly, otherwise the vehicle may be damaged.

Do not work under the vehicle if it is supported only by a jack.

Do not lift the vehicle with passengers.

– Rotate the jack handle and lift the car.

If the vehicle is being lifted to change a wheel, lift it only high enough to remove the wheel;

– after completing all work, remove the jack;

– before starting to move, make sure that all tools and the jack are in place and securely fastened to prevent injury in the event of a collision or sudden braking.

To avoid damage to the underbody and the vehicle falling, install lift supports only in the recommended locations.

Do not start the engine or engage gears with a raised vehicle if at least one wheel of the vehicle is on the ground.

Do not lift the vehicle by the oil pan, transmission, or front or rear axles, as this may damage the vehicle.

RAV4 rear suspension diagram

Regardless of the year of manufacture, Toyota RAV4 vehicles use an independent wishbone suspension for the rear wheels. Telescopic shock absorbers and coil springs with nonlinear rigidity are used as elastic elements.

The design includes a stabilizer bar. To adjust the camber up to the fourth generation, a cylindrical wishbone with a length variable using a threaded bushing was used, which was later replaced by a bolt with an eccentric head.

Where is the jack located on a Toyota RAV4?

In this article we will look at a topic that can be useful to everyone. Whether it's because you have a flat tire or you want to replace your brake pads, knowing where the jack is on your Toyota RAV4 is important. Obviously, without a jack, you won't be able to lift your car and therefore change a wheel or access components behind it, such as brake pads. To achieve this, we will first explain the different types of jacks, then where the jack is located on a Toyota RAV4, and finally how to use a jack on your vehicle.

What types of jacks are there for Toyota RAV4?

- Single Lever Jack for Toyota RAV4: The first type of jack, the most classic and cheapest of all, is usually found on entry-level models or those with few options. This type of jack has only one articulated arm that is placed under the vehicle to lift it. This type of jack is lightweight and easy to use, but does not allow you to lift large loads.

- Double Lever Jack for Toyota RAV4: It uses the same principle as the jack shown above, i.e. a worm screw which allows the jack to be screwed on to raise and unscrewed to lower it, however, using a double lever will result in a more stable jack that can lift a higher payload.

- Hydraulic Jack for Toyota RAV4: This type of jack does not come standard on vehicles and usually only comes with the premium model or is purchased from auto centers. These jacks are heavier, generally less bulky, and have the advantage of being much easier to use and capable of lifting larger loads. Their purchase will cost from 20 to 50 euros, here is a simple and effective model from Oscaro.

Where is the jack on Toyota RAV4?

- Most often, the jack is located in the trunk of a Toyota RAV4. To get to it, simply lift up the trunk carpet and you should be able to find it and the spare tire.

- In the rear wheel well: In a similar but less common position, your jack may be in the trunk, but to the side of it, to get to it you simply need to open the hatch on the right side of the trunk.

- The last possible location for a jack on your Toyota RAV4 is under your vehicle. If you still have a spare tire you will find it under the trunk, in most cases you will have to unscrew a nut to release it and the spare tire.

How to use a jack on a Toyota RAV4?

- Before lifting your Toyota RAV4, be sure to engage the handbrake as well as the gear to lock the wheels.

- Remove the wheel nuts from the wheels you want to work on before lifting the car, otherwise you risk damaging the transmission.

- Start raising the jack (about 20 centimeters) and place it under the car at the level of the underbody; in most cases you will find a notch to place it in the desired location.

- Raise your Toyota RAV4, don't worry about it, if your tire leaves the ground three inches, that's enough.

If you need more Toyota RAV4 guides, go to our Toyota RAV4 category.

Rear control arms of Toyota RAV4

The suspension elements are mounted on a spatial steel subframe attached to the body side members. The levers are equipped with rubber hinges (silent blocks), ensuring the mobility of the elements within limited limits. The chassis design includes asymmetrical transverse elements, complemented by a trailing arm with a support attached to the underbody. The configuration of parts depends on the generation of the crossover.

Upper transverse

The upper arm is equipped with a pair of rubber hinges and is made using hot stamping technology. The element ensures the positioning of the fist with the brake mechanism and the wheel. On cars of the 1st and 2nd generations, the shock absorber was attached to a cup in the body; starting from the 3rd generation, the upper fixation point of the strut is located on the subframe next to the traction joint.

The upper wishbone is made using stamping technology.

Lower transverse

The lower element is made using stamping technology from a thick-walled steel sheet and has an annular recess for installing a spring. The lever swings in a vertical plane on hinges together with the fist and the wheel.

To prevent noise and reduce wear rates, durable rubber gaskets are placed on the ends of the spring.

Longitudinal

The longitudinal element is rigidly bolted to the knuckle. The opposite end is equipped with a hinge that provides vertical suspension travel. The movable support is installed in a stamped bracket, screwed to the reinforcement on the lower part of the body side member.

The trailing arm is bolted to the knuckle.

Where is the jack on the Land Cruiser 200 and how to use it

It is difficult to immediately determine where the jack is located in the Toyota Land Cruiser 200, because each car manufacturer arranges the contents of the luggage compartment in its own way.

Where is the jack on the Land Cruiser 200

To accommodate the standard lifting device in the Land Cruiser, the designers of the Japanese company used the lower left part of the trunk. There, under the wall panel, they chose a place where they needed to find a special removable hatch. In the removed position, it provides access to a special niche with a device that allows you to lift the car.

To pull out the lift, you must first loosen it, otherwise you won’t be able to get it out. The same compartment stores the knob and the hook that is inserted into it. Without these parts it is impossible to lift the machine. It is important to keep them in one place.

Selecting a jack for TLC 200

If a standard lift is not included in the package, then there is a need to purchase this accessory, which is extremely important for the normal operation of the car. After all, without it it is impossible to remove a flat tire. And here the choice depends entirely on the preferences of the car enthusiast.

Small hydraulic jacks have a dead weight of only 5 kg, and the lifting height is limited to 29 cm. The bulk of these tools are manufactured in China. A noticeable disadvantage is the inconvenience of use on uneven and unstable surfaces.

The weight of the electric diamond jack is less than 4 kg. At the same time, he is able to lift the car by 345 mm. The device is equipped with microswitches that provide emergency release. The lifting procedure takes place at a leisurely pace, but the package includes an electric impact wrench.

The telescopic bottle lift, made in China, also weighs 4 kg. The reach of the lifting part is 42 cm.

How to jack TLK Prado

Before placing a jack on the Land Cruiser 200, the car is placed on a flat horizontal surface. If it is not possible to find one, then the following precautions are taken:

- The parking brake is set to the extreme position.

- The selector lever is set to position “P”.

- Wheel chocks are installed under the wheel, located diagonally from the jacked area.

It is not recommended to move far from a lifted vehicle, especially if there are children nearby!

Before lifting begins, the decorative cap is removed and the fastening nuts are loosened using a wheel wrench. It must be remembered that the lifting device cannot be placed under the sills, oil pan, floor panels, suspension or steering components. An SUV frame or beam is used for this.

After the jack is placed under the car, you need to make sure that its head is securely engaged. Using the jack handle, the car is raised to such an extent that the wheel being replaced is lifted off the ground. Only after this the nuts are unscrewed and the faulty part is removed to be replaced with a functional one.

As soon as the entire set of nuts is screwed in, the car is lowered to the ground. The jack, having fulfilled its function, is returned to its original state and placed in the place allocated for it.

If it is necessary to perform serious work with the help of a lift, then it is secured with special supports placed under the machine. Under no circumstances should any work be carried out under the bottom of a vehicle supported by only one jack. This is extremely life-threatening!

Analog parts

Since original parts from Toyota have a high price, many owners are looking for components from alternative suppliers. The spare parts market contains products from factories in China, Europe and Southeast Asia. A common disadvantage of compatible products is unstable quality (even within the same batch), so the use of such units is fraught with additional costs for repeated repairs.

Fenox

Chinese components are supplied under the Fenox brand, declared as Russian-Belarusian.

Fenox supplies Chinese components.

The parts are packed in boxes with original markings (products from different manufacturers can be supplied under the same article, which negatively affects the quality). The components are suitable for budget repairs or before selling the car, but the suspension life will be from 5 to 15 thousand km (depending on operating conditions).

TRW

The American brand TRW Automotive supplies components to plant conveyors and to the spare parts market. The quality of products depends on the place of manufacture (the company packages some parts from Chinese enterprises in its own containers and sells them as its own products).

There are catalogs on the manufacturer’s website that allow you to select components based on the machine model and design features.

JapanParts

The company is registered in Italy and belongs to the category of companies that package products from manufacturers from Southeast Asia in original containers with their own brand. Buyers note the unstable quality of components, which depends on the batch and supplier. The advantage is the low price and availability of parts in warehouses (delivery time varies from 1 to 3 days). JapanParts components are suitable for budget repairs, but the service life of the chassis will not exceed 1.5–2 years.

JapanParts products are low priced.

Masuma

The Japanese supplier offers components manufactured in factories in Southeast Asia. The parts correspond in size and material to factory samples and withstand harsh operating conditions. Metal surfaces are covered with primer and an additional layer of impact-resistant enamel, which protects the material from the effects of road reagents and water. Masuma uses frost-resistant rubber that does not crack during cyclic temperature changes.

Febest

The company is registered as German, but its production facilities are located in China. The products have a low price and are suitable for emergency repairs or restoration of the chassis before selling the car. Some components under the Febest brand are manufactured in large factories and are of good quality, but the majority of parts fail after 2–3 years of operation.

Febest is suitable for emergency repairs.

ASVA

The ASVA brand supplies components manufactured by several Chinese enterprises. Buyers note the increased rigidity of the rubber used, which negatively affects comfort and service life. The paintwork is not very durable; traces of corrosion appear on the levers after 2–3 months of winter use (road reagents accelerate the process of metal rotting).

Toyota Carina E

Added after 55 seconds: Make thresholds in these places, then they will start to rot.

As I understand it, in order to avoid problems with jacks in the future, it makes sense to acquire something similar to this:

As I understand it, you made this crap yourself. If so, how?!

For the future, be sure to make sure that tire fitters at least have spacers from old tires on their jacks. I almost jacked up one Khachikyan myself when he reached under the stiffening ribs with a bare jack.

No, I found this crap on the forum of mischief makers (damn, it’s like a dirty word). I'm thinking of making a lighter version, in the form of a sawed-off hockey puck. My father claims that without the “cup” it will fall apart right away, I think I’ll try it in the near future

Added after 45 seconds: And there was a gasket on the jack, yeah.

I'm wondering now. I like the option made from pieces of thick plywood, the support area will be larger. 2-layer construction: the bottom piece is solid, on top of it are 2 narrow pieces of plywood, the space between them is for the sill stiffener + rubber on top

I use the board myself, but it often cracks under the influence of this very edge

| Attachments: |

| 1.JPG [6.98 KB] Downloads: 1 |

_________________

Toyota Carina E GLi, England, 1994, sedan ST191L-BEMNKH, 3S-FE 2.0, ABS, manual transmission S54, color - 742, sunroof, Multitronics VG1031UPL + PU-4TC Drive2

How to make a real SUV from Toyota RAV 4

There is a certain category of jeepers for whom modifying a car is such an exciting process that they appear on road trips 4-5 times a year, and spend the rest of the time in the garage, bringing their favorite SUV to a “pre-cut” state.

It so happened that I have no interest in participating in off-road competitions, and tourism and search activities have come to the fore, since I am a member of the M.P. Krasnopivtsev Vocational Educational Institution. The car becomes a good assistant in this right task. Many battlefields of the Great Patriotic War are reached only by front-line roads and directions, and to them there may be 200 km of asphalt and only then off-road.

Despite its “parquet” origin, the car began to look very brutal

After the experience of owning a heavy SUV, I came to the understanding that the decisive factor influencing off-road performance, in addition to “toothy” tires and suspension lift, is the weight of the car.

This was the reason to immediately cut off all cars weighing more than 1400 kg. After going through several options, I settled on the Toyota RAV4. It does not have a frame or a reduction gear, but the first and second generations have an honest full-time with a locking center differential. Let's look at the weight - 1190 kg, engine power - 129 hp. With.! A car for tourism means long runs on asphalt and short distances on moderate off-road conditions. Is a frame and lowering necessary for touring if the body is rigid, short-wheelbase, and the engine has a decent power reserve?

Space. The rear row of seats has to be folded when traveling, otherwise the meager trunk volume cannot be increased

Structurally, the car is simple, which guarantees a certain reliability. After all, the fewer nodes, the less likely it is that one of them will break.

The manual transmission housing houses the front axle and a cross-axle differential with pneumatic locking; from the gearbox flange there is a driveshaft with CV joints and one suspension bearing directly to the rear axle. Thus, there is no transfer case as a separate unit, which, among other things, “eats up” the ground clearance.

The cost of replacing transmission fluids is significantly reduced, because you only need to change the oil in the rear gearbox and gearbox.

In my time. When lifting the suspension, it was decided to “finish” the standard shock absorbers. To increase the length, an additional ear is welded to them. Doesn't look great, but works well

The 3SFE engine is very common in the Toyota model range. It is not afraid of overheating, oil starvation, and does not bend valves when the timing belt breaks. With a real consumption of 10 liters on the highway, one tank is enough for 600 km. Excellent access to attachments. Surprisingly, the generator is already positioned as high as possible - a small thing, but nice!

The search for a suitable copy began, and after a while a broken RAV4 with a manual transmission from 1995 ended up in my hands. First of all, I took the car to body repair and engine repair. Afterwards - painting, anti-corrosive cavities, sound insulation, welding in the required places, sealants, replacement of the windshield, complete revision of the wiring.

The radio antenna and the canister on the rear door are designed in military style

And finally we got to the most interesting part: the transformation of a “SUV” into a “tourist”. Here you need to try to enhance the advantages of the car, leveling out the disadvantages. The advantage of split bridges is decent ground clearance. That's why we're doing a suspension lift. At the front there are 25 mm spacers between the cup and the strut and rear springs from MPS - they match the standard coil diameters, but the number and thickness of coils are greater. At the rear we install reinforced KYB springs from Niva. Regarding the shock absorbers, I decided to go with the standard ones and then install an increased stroke, so I welded another “ears” from below to increase the stroke. It would be more correct to increase the stroke from above: the compression point of the springs moves lower, and wheels of increased diameter with the springs compressed to the maximum will not touch the arches.

Since there is no reduction row, I didn’t get carried away with larger wheel diameters. The stock wheels are 215/70/16. I installed Hankook RT03 MT tires in the following standard size - 225/75/16. The arches had to be widened from the inside so that the wheels would not rub the fender liners when cornering. For this tire size I chose forged wheels Mickey Thompson Delta with dimensions 16×8, ET and weighing 10 kg.

Cunning. The lack of a frame when driving off-road is a big disadvantage; the crossbar adds additional rigidity

The linkage has been removed to create decent off-road suspension articulation. There is no need for any other changes to the suspension. As a result, clearance measurements under the underbody protection showed 29 cm in front and 30 cm under the rear axle. Well, great result!

For a long time and painfully I decided on the winch. In the end, I settled on the “Stokrat” ATV4000Lb, and purchased a unit to be on the safe side. The platform was made from a thick-walled profile pipe and installed at such a level that the winch was hidden in the bumper. This immediately required shortening the steel cable by half. The solenoid block is located high under the hood. In general, the design was light, but with a margin of safety.

The trunk in the car is quite small, but it is enough for a bag with a compressor, a trunk with a first aid kit and rigging. And on the third door there was an ax, a shovel and a lantern in self-grabbing fastenings.

Neighbours. The radio station and toggle switches for controlling additional light ergonomically fit into the center console

What is a touring car without an expedition rack? I installed a battered trophy aluminum basket on the Atlant supports. It seems a little high, but you can open the hatches for ventilation mode. And in order to remove the hatches, we had to remove two middle jumpers.

Hidden under the trunk is a diode light - front (120 W) and rear (40 W). This made it possible not to be afraid of damaging the “chandelier” when driving through forest roads with overhanging branches. If necessary, you can remove the basket by disconnecting the wiring connector. The light is turned on by helicopter-type toggle switches located in the center of the console.

The snorkel is a safety attribute. This does not mean that now you can dive to the very roof - at least the distributor will not forgive this. However, it often happens that the car “catches” a water hammer in the most harmless puddle. Therefore, it is better to spend a certain amount on a snorkel, symbolic compared to the cost of engine overhaul. The snorkel on the RAV4 probably exists in nature, but one cannot be found in Russia. I had to resort to world experience: at an international RAV4 forum (and there is such a thing), I found a car from an Englishman with a snorkel from TLC Prado 90 that fit perfectly into the 1KZ (let there be at least something from the legendary engine). Having modified the air filter housing, I mounted the snorkel, having previously cut off 6 cm of pipe from the top so that it did not look like a periscope, and made another plate for attaching to the rack.

Suspension. The entrenching tool is secured to the rear door with “quick releases”. Convenient, practical, and saves space in the luggage compartment

I refused the spare wheel simply because of my experience with MT tires. Of course, a spare tire is needed for long journeys, and within the region I have friends who will bring it if necessary.

I decided to install a CB radio, but I didn’t want to put the antenna on the roof and then have fun rattling it along the branches in the forest, and I also wanted to have an additional canister outside. Firstly, a certain army ambiance. Secondly, there will be no smell of gasoline in the cabin. Thirdly, every liter of trunk volume counts. I installed the antenna on the canister mounting frame so that it would not protrude above the expedition trunk, and hung the canister itself on the third door. The radio is located in a niche instead of a shelf, and the PTT switch is located under the steering wheel. No extra wires, and everything is at hand. Instead of the “original” front seats, I installed seats from TaGAZ Tager - they have wide and high cushions and backrests, which is very convenient on long trips.

On the first trip after installing the engine, we went to the harsh forests of the Smolensk region, where we had to overcome logging ruts and virgin soil - a kind of reconnaissance in force. The machine, despite all the difficulties, successfully coped with this task.

Towbar. It acts as a powerful towing eye and protects the rear overhang from damage.

Future plans include installing a rear gearbox with Torsen locking from a Toyota Celica GTFour and rear disc brakes from Toyota Ipsum (oh, this “Toyota” unification). Make protection for the gas tank, reinforced adjustable transverse links of the rear gearbox and a remote rod for additional light. But this is already on long winter evenings. In the meantime, while the season is not closed, my little soldier on search expeditions is helping to establish the names of the heroes, thanks to whom the day of the Great Victory finally came.

The device of a rolling jack: how to use it, where to rest it, how to lower it

Rolling jacks have a stable support, but the device has a low operating speed, which is especially noticeable when lifting cars with high ground clearance. However, for more professional models with two plungers, this indicator is not critical.

It is also worth considering that hydraulic models are not recommended for use at very low temperatures. In addition, the jack should not be left raised for a long time without additional stops. Since when the pressure in the cylinder drops, the device may sag.

How to use a rolling jack

- When using any modifications, you should select a site where it will be easy and safe to place the rolling jack. Ideally, it should be a flat, solid base: concrete floor, asphalt, etc. A rolling jack is usually not used outside of workshops or garages, but if there is such a need, you will have to carefully select the installation location. It is prohibited to use it on pressable surfaces (loose soil, dirt road, rain field). This could cause the lifting mechanism to become dislodged, causing the machine to fall off or be damaged.

- Compliance with the load capacity is the basic rule when working with a rolling jack. If work is carried out on a car, then you need to take into account not only the weight of the car, but also the presence of cargo in the luggage compartment or cabin. If possible, the vehicle should be empty.

- After raising the car or other equipment to the required height, safety stands (special or hemp) are installed, and the jack itself is removed. Only after this can you begin to carry out repair work.

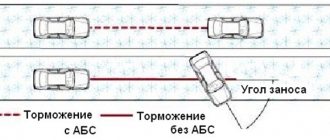

The question often arises about where to rest a rolling jack, the supporting platform of which differs from the lifting foot of a standard jack. In some cases, with insignificant weight and short lifting, the rolling jack can be rested against the stiffening ribs (only in specially marked places). But it is better to look for the exact answer to this question in the instruction manual, where the locations on the underbody for installation in the front and rear of the car are indicated.

- To save time, when replacing two wheels at once, place a rolling jack in the center of the threshold. Maybe not the first time, but the threshold will definitely break.

- Use a jack without a thick rubber cushion (gasket). Few manufacturers include gaskets as standard, but this does not mean that they are not needed.

- Jack up the car under the trunk. Despite the visual strength of the threshold along its entire length, it is reinforced only in the marked places. Lifting the car behind the rear wheel will inevitably result in dents and an unstable jack position.

To lower the raised equipment, the release valve opens and the process proceeds in reverse order. But before lowering the rolling jack, you need to make sure that all parts are secured and that the load or machine will take a stable position after lowering.

Tips for use

- Before jacking up the car, it must be put on the handbrake.

- The car should not stand on an inclined plane while using the jack.

- The nuts on the wheels should be “torn off” before lifting on the jack. Otherwise, the jerk may cause the machine to jump off the supporting device.

Also, when working independently, do not forget that a thick cushion (adapter) made of thick rubber should be placed under the lift stop. This will protect the machine body from damage and premature corrosion. It is recommended to place studs, iron shoes or other objects under the wheels of the car.

Maintenance and care

- The rod will not rise.

- The jack does not support the load.

- Oil smudges appeared on the body.

- A specialized flushing fluid for jacks is poured into the oil filling hole. You can purchase it at construction stores or auto parts stores.

- To distribute the liquid throughout the system, a lever is activated.

- Then add fluid again and move the lever. The procedure is repeated until the rod reaches the top position.

- Turn the exhaust valve and return the piston to its original position. Then the cleaning liquid is drained.

- If there are traces of contaminants in the liquid, the system is filled with liquid again and flushed again.

After the final flushing of the system, the flushing liquid is completely drained and the structure is assembled. Then you can start “pumping the hydraulics” - filling in the working oil. The unit is filled with oil according to the scheme described above: oil is added to the filling hole (it remains open to allow air to escape), and the rod is lifted up using a lever. When the stop is extended to the maximum, open the exhaust valve and lower it to its original position. Excess liquid is poured out. The filling hole is clogged, and excess oil is wiped off the jack body. After this, the device is ready for use.

- Oil is drained from the apparatus through the filling holes into the prepared container, and the structure is disassembled.

- After disassembly, you need to inspect the pistons. If there is plaque or rust, clean the parts with a rag soaked in gasoline, diesel fuel or white spirit.

- The next step is to check the valves. Clogging indicates the need to clean or replace the part.

- Change sealing elements in a timely manner. Their wear is indicated by fluid leaks on the body.

- Monitor the oil level in the system.

- Check the rod and guides for corrosion processes.

- Lubricate all moving parts with grease.

- Ensure compliance with load capacity standards.

- Keep the device clean by wiping it with a soft cloth.

- Do not use the jack as a support mechanism. Any model of jack is designed to lift, not hold, a load.

- The device should be stored in a dry place with the heel down and the stem retracted.

Do-it-yourself replacement of rear control arms on a Toyota RAV4

To carry out self-service, you will need a garage box with an inspection hole or a lift. The car must be secured under the wheels or placed on supports. A set of wrenches will be required for disassembly and assembly (it is recommended to provide a torque arm to ensure the required torque). Because the underbody threads are coated with dirt and rust, you'll need a wire brush, rags, and a rust remover (such as standard WD-40).

Upper wishbone

To replace the upper arm you need (using the example of a 2013 car):

- Unscrew the wheel fasteners and remove the disc from the hub.

- Unscrew the nuts holding the ABS sensor wire, and then remove the cable from the suspension arm.

- Using a rolling jack with a wooden block or a hydraulic rack, set the suspension to the normal position.

- Remove the 2 bolts holding the rod to the subframe and knuckle. Since the design uses self-locking fasteners, you should turn the bolt while holding the nut with the socket head.

- Clean the mounting surfaces and holes from dirt, and then install the new lever.

- Insert the bolts into the holes and pre-tighten.

- Set the suspension to the normal position (corresponding to the load from the weight of the equipped vehicle), and then carry out the final tightening with a torque of 90 N*m (the bolt head should be rotated while holding the nut with a wrench or socket).

- Reinstall the ABS sensor cable by tightening the nuts to a torque of 5 N*m.

- Mount the wheel on the hub and remove the car from the jacks.

- Check and adjust the wheel alignment angle in a specialized service center.

To replace the upper arm, you must remove the disc from the hub.

Lower wishbone

To replace the camber transverse elements of the suspension, it is necessary (using the example of a car produced in 2013):

- Loosen the nuts, lift the car on a lift and remove the rear wheel.

- Using a pair of wrenches, unscrew the camber arm from the subframe.

- Using a spatula, remove the bolt from the hole and remove the rod from the bracket.

- Place a hydraulic support under the lower shock absorber mounting point, and then move the suspension to its normal position.

- Use a socket to unscrew the bolt securing the shock absorber to the knuckle.

- Move the strut housing away, unscrew the camber lever fastening.

- Use a puller to remove the ball pin from the mounting hole.

To remove the lower arm you will need (using the example of the RAV4 II generation):

- Unscrew the stabilizer link nut and the bolt securing the arm to the knuckle.

- Remove the suspension spring from the mounting hole and move the lever down.

- Remove the floating joint from the hole using a mandrel (for example, a steel pipe of a suitable size). The manufacturer does not supply original silent blocks, offering a replacement knuckle assembly, so to complete the work you will need components from a third-party supplier.

- Apply a thin layer of lubricant to the hinge body and insert it into place, and then reassemble the assembly in the reverse order.

Trailing arm

To change the longitudinal element of the rear suspension, it is necessary (using the example of a 2007 model year car):

- Remove the wheel and then unscrew the handbrake cable mounting bolts.

- Set the suspension to a position that corresponds to the load of the weight of the equipped vehicle (for example, using a jack installed under the front part of the brake disc).

- Unscrew the bolts securing the lever from the knuckle, and then remove the element from the body along with the bracket.

- Place the new part in place and tighten the fasteners.

- Secure the handbrake cable, remove the jack and replace the wheel.

When performing work on the rear suspension on a 2008 RAB-4 crossover (or any vehicle with an independent wishbone design), wheel alignment may be compromised. Some owners pre-apply marks to the eccentrics and subframes that correspond to the correct adjustment. After completing the work, the bolt is returned to its original position. To improve handling and reduce the rate of tire wear, it is recommended to check the angle on a bench, since new hinges and arms can negatively affect the adjustment.