The Japanese Toyota 4.5 1FZ-FE engine was installed on the Lexus LX and Land Cruiser sold in our country.

The Japanese concern produced this engine for seventeen years with minimal changes , except that in 1998 the outdated distributor was replaced by ignition coils. For developing countries, a carburetor version of the engine with the index 1FZ-F was produced.

Motor Toyota 4.5 1FZ-FE

Characteristics of the 1FZ-FE engine

The 1FZ-FE motor is tenacious. Despite the fact that production ceased long ago, cars equipped with it are still found on our roads.

Specifications:

- years of production: 1992-2009;

- exact volume: 4446 cc ;

- power (hp): 212 hp at 4400 rpm /min;

- torque (N/m): 373 N/m at 3200 rpm;

- compression ratio: 9.0;

- lubricant change frequency: 7-10 thousand km;

- permissible oil consumption: up to 1 liter per 1000 km;

- engine oil volume: 7.4 l;

- ecological class: no data;

- fuel used: AI 92;

- power supply: injector;

- cast iron cylinder block;

- number of cylinders: 6;

- number of valves per cylinder: 4;

- piston stroke: 95 mm;

- cylinder diameter: 100 mm;

- Timing – chain;

approximate resource: more than 400 thousand km.

Timing belt 1FZ-FE

Fuel consumption

The Land Cruiser 100 4.5 with a 5-speed manual transmission and all-wheel drive cannot be called light, so its gasoline consumption is appropriate.

Fuel consumption of a car equipped with a 4.5 1FZ-FE engine:

- city: 22.4 l/100 km ;

- highway: 13.3 l/100 km .

Land Cruiser 100

Design Features

The 1FZ FE inline 6-cylinder engine is equipped with a cylinder block made of cast iron. The engines use an aluminum head on which 2 camshafts are installed. The gas distribution system drive is chain, equipped with a hydraulic tensioner and damper. The chain drive gear is installed on the intake valve shaft, which is connected to the 2nd shaft using a helical gear drive. The serial number is stamped on the side of the block at the rear (behind the oil level dipstick).

The upper section of the oil sump, made of aluminum, is installed on the lower part of the block. The section is attached to the engine and clutch housing. Additionally, a stamped steel pan is installed, which serves as a reservoir for storing oil. There is a drain plug in the pan located closer to the clutch. The oil filter is installed on the side of the block behind the generator.

Each cylinder has 2 valves for the intake of the working mixture and 2 valves for the removal of exhaust gases. The valves are installed in a V-shape, with a slight camber angle. The clearances in the valve mechanism are adjusted using washers of various thicknesses. The steel crankshaft is mounted on 7 main bearings equipped with replaceable bearings. Each support has an individual cover. The crankshaft has 12 counterweights.

The pistons are made of a special heat-resistant aluminum alloy. The upper compression ring is made of stainless steel, the lower compression and oil scraper rings are made of cast iron. There is a recess on the bottom corresponding to the contour of the valve plates of the gas distribution system. If the timing chain is broken, there is no contact between the piston and the valves. The spark plug is located in the center of the combustion chamber. The engines use a system for removing part of the exhaust gases into the intake manifold (recirculation).

On carburetor engines the compression ratio was 8.1. The introduction of the EFI injection system was accompanied by changes to the piston group and cylinder head. The compression ratio increased to 9.0.

Early engine releases were equipped with a contactless ignition system with a distributor. The assembly is located horizontally on the side of the crankcase. Later, a system with three coils was used, each of which served 2 cylinders. On engines manufactured after 2000, individual ignition coils are installed, which ensure increased system reliability.

The engine uses 2 exhaust manifolds, which are covered with heat shields. The intake manifold is aluminum. The design of the unit depends on the type of power system. The throttle valves on the carburetor and injection module are mechanically controlled.

The fuel used is unleaded gasoline with an octane rating of A-92. Fuel consumption is 15-25 liters per 100 km, depending on the type and condition of the car, as well as on the driving style.

The cooling system is liquid forced. The block and head have channels that form a cooling jacket. The engine operating temperature is +84…+100°C, maintained by a thermostat. To drive the cooling system pump and generator, 2 V-belts equipped with a separate tension roller are used. The roller position is adjusted manually. The cooling system fan is installed on the front of the engine. The drive uses a clutch; the rotation speed of the impeller depends on the temperature of the power unit.

The power steering hydraulic pump is driven by a gear mounted on the crankshaft. The air conditioning compressor (not available on all engines) is equipped with a separate belt drive. To adjust the tension, a separate roller with manual position adjustment is used.

Technical features of the 1FZ-FE engine

The most voluminous in the Toyota line of six-cylinder engines was 1FZ. Developed for the Land Cruiser, this engine surpassed its competitors in reliability .

The previous modification 1FZ-F had a carburetor , this ensured the simplicity and reliability of the design. The restyled FZ-FE engine was equipped with fuel injection , the intake and exhaust manifolds were also changed, and the compression ratio was increased. These innovations have a positive impact on the dynamics of the car.

Carburetor engine 1FZ-F

The cylinder block is cast iron, so the 1FZ-FE weighs a considerable 265 kg . Excess weight is added by all the parts manufactured for many years of operation. The displacement engine has an appetite of up to 25 liters per 100 km , but this figure is no higher than that of its competitors.

But what kind of efficiency can we talk about if the engine was originally created for a heavy SUV. There are no hydraulic compensators , so it is necessary to check the valve clearances from time to time. Oil is also consumed in large quantities ; in engines with high mileage, it is sometimes necessary to add up to one liter of lubricant every thousand kilometers.

Cylinder block 1FZ-FE

Problem areas of Toyota 1FZ power units

In the best traditions of the 80-90s, Toyota, 1FZ has signature simplicity and enormous reliability. After all, at that time, products were created by engineers, not marketers. Based on this, there are practically no design flaws in the engine, and the resource life is legendary. The engine is extremely easy to maintain; it never required any frills in terms of oil or fuel.

With simple, but timely and high-quality care, the power unit travels at least 400,000 km without requiring major repairs.

Due to its simplicity, the engine will not please you with its low consumption. Frankly speaking, it “eats” fuel in huge quantities, taking into account the cost of gasoline, installing gas equipment is becoming a truly urgent undertaking. In other aspects, this is an excellent resource and productive motor.

Service

The Toyota 4.5 1FZ-FE engine is unpretentious in maintenance, but timely maintenance can still provide a longer service life.

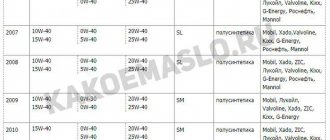

- The oil should be changed every 7-10 thousand km . Viscosity from 5w-30 to 15w-50 , this parameter should be selected based on climatic conditions; it is not recommended to fill in a lubricant that is too fluid.

- Replacing the air filter depends on which roads the car is driven on most often and from 7 to 15 thousand km.

Air filter. Original - Toyota does not have hydraulic compensators, so you will have to adjust the valves every 40-50 thousand mileage. The gaps are measured on a cold engine:

- at the inlet from 0.15 to 0.25 mm ;

at the outlet from 0.25 to 0.35 mm .

- Spark plugs are changed every 30 thousand kilometers ; their service life can be shortened by bad fuel and malfunctions in the ignition system.

- Some owners have a timing chain that lasts up to 400 thousand , but it’s better to take care of it earlier.

Valve adjustment is carried out according to clearance tolerances

Disadvantages and weaknesses of 1FZ-FE

To find the weak points of this motor you have to try hard. If there is a failure in the gas distribution system, the valves do not bend ; thanks to the grooves on the pistons, the timing chain drive is reliable. The 1FZ engine is designed to be strong and durable.

Piston 1FZ-FE

The cast iron cylinder block is practically not deformed from overheating . The piston group can serve 400 thousand , and after overhaul its service life is extended by the same amount. Oil seals rarely leak, and there are no problems with crankcase ventilation.

Toyota has developed a simple, repairable engine. However, there are downsides. There are only two of them - high fuel consumption and relatively high oil consumption.

Malfunctions and repairs

Engines of the 1FZ series have proven to be reliable units; breakdowns occur due to natural wear and tear:

- Whirling noises during operation of the power unit indicate wear on the adjusting washers in the gas distribution mechanism. It is necessary to perform adjustments and replace worn parts.

- Increased oil consumption without the appearance of blue smoke from the exhaust pipe. It is necessary to inspect the engine; fluid is leaking through a worn crankshaft oil seal or through a damaged gasket. For repairs, it is necessary to install new parts and bring the oil level to normal.

- The cooling system pump may leak. The unit cannot be repaired; replacement with an original part is recommended.

Tuning

Toyotas of those years are actively used in off-road competitions. Athletes and heavy off-road enthusiasts often increase engine power. Tuning can be done in two ways:

- The TRD company produces a kit kit for Toyota. Can install a compressor or turbocharger. This allows you to remove from the engine up to 300 hp But at the same time it is necessary to install a larger radiator, otherwise the system will heat up.

Eaton M90 compressor - In the second case, the cylinders are bored to five liters and a reinforced crankshaft is installed. In this case, you can achieve power up to 350 hp . However, this method is expensive and complex.

When combining two boost methods, you can achieve a power of 400-450 horses from the 1FZ-FE.

What cars was it installed on?

Toyota Land Cruiser J70

Initially, the Toyota 4.5 1FZ-FE engine was designed for the Toyota Land Cruiser , but then the premium Lexus acquired this unit.

- Toyota Land Cruiser J70 1992 – 2009;

- Toyota Land Cruiser J80 1992 – 2006;

- Toyota Land Cruiser J100 1998 – 2007;

- Lexus LX 450 J80 1995 – 2007

Lexus LX 450 J80

Purchasing a contract engine

There is a project based on the Toyota Supra and the 1FZ-FE engine, the maximum output was 2,500 hp. With.

Finding a contract engine is not difficult. Auto repair shops in the Russian Far East are littered with these engine models. Prices for this model range from 60,000 rubles to 150,000 rubles. It all depends on the condition and mileage.

Instead of 1FZ-FE, they often install more modern engines such as 2UZ or 3UZ in their cars. As a rule, the budget for such a “rework” will be from 400,000 to 500,000 rubles.

List of cars on which the Toyota 1FZ-FE engine can be installed

This engine was installed on the following cars:

- Toyota Land Cruiser 70, 80, 100;

- Lexus LX450.

Despite the reliability of the Toyota 1FZ-FE engine and the long period of use by Toyota, other automakers did not want to purchase it.

Toyota Land Cruiser 80