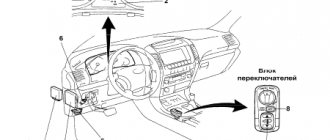

KDSS first appeared on the premium SUV Lexus GX470. Then the high-tech system migrated to the LC 200 and Prado 150. Cars in the Prestige and Luxe configurations are equipped with active anti-roll bars, regardless of whether the suspension is installed - air or conventional. The task of the system is to provide constant ground clearance and reduce the roll of a 3-ton SUV in corners, and on off-road conditions to “unclamp” the suspension and improve geometric cross-country ability. The Toyota Prado 150 KDSS system consists of two hydraulic cylinders, anti-roll bars, a valve block with two hydraulic accumulators, an electronic control unit and high-pressure lines.

Classic rigid anti-roll bars on the Prado 150 are connected to the body through hydraulic cylinders located on each axle. When the car moves on a flat road, the electronic control unit creates excess pressure in the system through valves and compensation accumulators. This blocks the hydraulic circuit, limiting the mobility of the stabilizers. Thanks to the “clamped” suspension, a heavy SUV with a high center of gravity shows good handling on the highway and does not “nod” when braking.

When off-road, the KDSS system reduces the pressure in the system and makes the stabilizers as flexible as possible, which significantly increases the off-road performance of the vehicle. The benefit of the system is especially evident when hanging diagonally, when, thanks to increased suspension travel, contact with the surface of all wheels is ensured.

While driving, the electronic control unit of the KDSS system continuously analyzes information about the vehicle speed, steering angle and, in accordance with the programmed program, regulates the fluid pressure in the system circuits using valves. To maintain stable pressure in the system and increase comfort, two bellows gas-filled hydraulic accumulators are located on the sides of the KDSS unit. The pressure value is controlled by a special sensor. If there is insufficient pressure or loss of system tightness, the KDSS warning lamp on the instrument panel lights up.

Toyota Land Cruiser Prado 150-series

The 150 series car has a number of features. First of all, they concern models with a diesel engine. Paired with powerful engines are manual and automatic transmissions.

The dimensions of the SUV are impressive. The interior is spacious, which is suitable for a large family or transportation of large luggage. Technical characteristics allow you to use the car in city mode, on the highway or off-road.

For greater comfort, Toyota Land Cruiser Prado is equipped with KDSS.

What is this, KDSS on the Prado 150, we will consider later in the article.

What is KDSS

The KDSS system on the Prado 150 is a kinetic stabilizer that ensures smooth movement and stability off paved roads. In simple words - suspension stabilization in off-road mode. It minimizes roll when cornering, making driving as safe as possible.

The KDSS is represented by a hydraulic device and is controlled electronically. As soon as the sensors signal a change in the road surface, the system instantly adapts to the new conditions.

Structure:

- 1 hydraulic cylinder located in the front and rear stabilizers;

- 2 hydraulic circuits holding together the spaces of the hydraulic cylinders;

- hydraulic cylinders for supporting the front and rear stabilizers.

When the machine deviates, KDSS stabilizes its position, which prevents it from overturning. When driving off-road, the pistons begin to move freely towards each other.

An experienced driver needs to understand, know well the KDSS system on the Prado 150 and what it is. This knowledge will help you repair the stabilizer if necessary.

Bleeding the KDSS system on Land Cruiser 200

Replacing any part (channels, cylinder, valve block) of the KDSS requires bleeding the system. The procedure is needed when the Land Cruiser 200 body rolls.

Before starting work, a visual inspection is carried out. It allows you to assess the integrity of the block, see cylinder leaks and damage to pipes and hydraulic parts. During pumping, high pressure is created in the CDSS (up to 50 kgf/sq. cm). If a fluid leak occurs during operation, the pressure is released and the leak is eliminated. Consumption is 4 liters.

How to pump the CDSS on a Toyota Land Cruiser 200:

- Unscrew the protective device of the stabilizer distributor.

- Remove the outlet plug and connect the high-pressure pump (SST). Fill it with liquid first. Bleed the air from the hoses.

- Loosen the flaps in the housing of the control unit for stabilizers and hydraulic accumulator (BUSG) by one or one and a half turns. It is prohibited to remove the damper. This will cause air to enter and liquid to splash.

- Using SST, liquid is supplied to the CDSS. The pressure should be no more than 50 kgf/cubic meter. see. Then check for leaks in pipes and hydraulic circuit elements. Add fluid to the BUSG (loosen the bleeder fitting of the control unit, use SST to expel air at a pressure of 5 MPa and tighten it).

- Add fluid to the lower and upper chambers of the front stabilizer control cylinder. The order is the same as when working with the previous block. The rear suspension element is pumped using the same principle. The procedure must be repeated until the liquid is completely cleared of air.

- Using SST, remove air from the CDSS. To do this, a pressure of 7 MPa is created and the bleeder fitting is loosened. Then it is tightened again to apply pressure. Repeat the process until the gases are completely released from the liquid.

- Disconnect the control arm and front stabilizer link. Set the length of the control cylinder to maximum (411.5–417.5 mm). This is necessary to expel air.

- Remove the anti-roll bar (rear) and strut. Set the maximum length of the control cylinder (386.5–392.5 mm).

- Remove air from the lower chamber of the stabilizer control cylinder (front, rear). Pressure - 7 MPa. Loosen and tighten the bleeder fitting until air is completely eliminated. Finally tighten it.

- Attach the front stabilizer control arm to the strut.

- Connect the rear stabilizer and strut.

- Apply pressure using the pump (SST) (all wheels must have support on the surface). To stabilize it, keep the parameters (2.6–3 MPa) for 1 or 2 minutes. The temperature of the liquid should be 20 degrees.

- Measure the height of the Land Cruiser 200. The difference in the suspension height of the right and left sides should be no more than 20 mm.

- Tighten the valves of the BUSG housing.

- Disconnect the pump from the suspension fluid inlet pipe and install the service valve plugs.

- Secure the stabilizer distributor protection.

Before installing the protection, it is necessary to check that there are no liquid leaks.

Adjustment of KDSS Toyota 200 should be carried out by professionals using special equipment.

The Land Cruiser 200 is equipped with a body height control (AHC) system. Can operate in manual and automatic modes (sets 3 positions). The system can be turned off. If it is faulty, the SUV may “fall”. After repair, the hydraulic suspension is pumped.

How to bleed the ahc system of Land Cruiser 200:

- Raise and lower the Kruzak 2-3 times;

- in the lower position, remove air from the receivers;

- the process is repeated several times.

Functions

The driver needs to know what it is - KDSS on the Prado 150, but there is no need to go into the details of its operation. This is due to the fact that the device is completely electronically controlled.

Main functions:

- ensuring smooth driving off-road;

- suspension stabilization under different driving conditions;

- ensuring safety during strong car rolls;

- improved stability in extreme conditions.

If there is a malfunction, the computer displays an error. When the failure indicator lights up, it means that the system is not able to function fully. Repair or replacement of parts is required.

Do you need KDSS or not: reviews from owners

Toyota offers the installation of KDSS as an additional option. The price of the car depends on it. This innovative development is expensive, but for regular off-road driving it is necessary to ensure safety.

- Igor: “I purchased a Prado from KDSS. I can say that with KDSS the car steers better, the stability is greater, and the ride is smoother off-road. There is something to compare with, my friend “Pradik” without it, on a fishing trip, all his brains were shaken out. I didn’t regret that I took exactly this configuration, as I feel safe while driving. Of course, this thing is expensive, I paid about 250 thousand rubles extra for the car, but my own life and health are more valuable. I drove about 100 thousand km, there were no breakdowns.”

- Andrey: “The first Pradik was pre-restaling without KDSS, now I bought it with the system. I don’t regret it, because the car corners much better and doesn’t roll. The stiffness of the suspension is, of course, strong, and it’s terrible on bumps. I’m happy with both options, the main thing is that the car doesn’t break down and nothing knocks in it.”

There were practically no negative reviews during the entire period of operation; all drivers were satisfied with the additional option.

Instructions for replacing brake fluid

If you don’t want to waste your personal time and are not afraid of the cost of performing this operation (from 800 rubles), then you should go to the nearest service station. But you need to understand that every car enthusiast with hands can replace the brake fluid on a Prado 150 diesel.

The algorithm for carrying out this work is as follows:

- Using a medical bulb, remove the brake fluid in the reservoir. In this case, a small part of it should be left at the bottom to prevent air from entering the system. A layer of no more than ten millimeters is left.

- Add new consumables to the compensation tank to the level marked MAX.

- With all possible care to prevent curling, open the fitting designed to remove air. To facilitate this action, it should be pre-treated (2 hours before) with a rust remover. If after taking the steps you cannot unscrew the fitting, you will have to go to a service station.

- Having gained access to the rear caliper on the disc wheel mechanism, we put one end of the hose on the air bleeder fitting. It must be clean and transparent. To place the second end, use any container, for example, a plastic bottle.

- An assistant should be asked to press the brake pedal until a feeling of resistance to pressing appears in the leg. Having depressed the pedal, it is held in this position, while opening the fitting. When the pedal falls down and hits the floor of the body, the air outlet is blocked. The procedure is repeated until no more bubbles appear in the transparent hose. During its execution, as a rule, about 0.5 liters of liquid are pumped out.

- We finally close the fitting and fill the compensation tank with new DOT 5.1.

- The same scheme is used to bleed all calipers or working brake cylinders.

- To dispose of old brake fluid, you should contact special points that accept used fuel and lubricants.

- To check the free play of the pedal, you need to press it. It should not move more than 1/3 of the full stroke.

- DOT 5.1. is poured into the tank to the required level, after which it is closed.

- To confirm reliability, the following steps are taken:

- the quality of fastening of hoses and pipelines is checked;

- The tightening of air bleed fittings is inspected.

- We start the diesel and make sure the system is tight. To do this, press the brake pedal 10-15 times with a force corresponding to 20-30 kilograms. In this case, the pedal should not move back. Once again, all connections are checked for leaks.

- The final test is carried out while driving on the road with intensive changes in acceleration and braking modes. The effect of ABS is confirmed by the pulsation of the brake pedal when you press it.

For those who still have questions about replacing brake fluid on a Toyota Prado 150, we recommend watching the video.

Reliability, faults and repairs

KDSS is reliable, but has a number of features. On cars with the system, a defect was identified, which consists of a leaky installation. Due to the accumulation of condensation, a malfunction icon lights up on the dashboard, vehicle controllability decreases sharply, and the device does not work properly. Code C1851 should mean that the sensor readings correspond to a pressure not exceeding 0.9 MPa (9.2 kgf/cm2, 130 psi).

The block shows corrosion. Moisture gets on it from under the control valve housing. After some time, corrosion damages the entire device.

If there is KDSS on the Prado 150 and the indicator is on, every driver should know what to do in this case. You need to check for condensation and remove it. This is the reason for the error, which is why the light came on.

To prevent damage, move the valve connector outwards and additionally treat the block with sealant. The usual procedure will protect against sensor damage.

Replacing the block

If the KDSS breaks down on the Prado 150, repairs are required. When condensation gets on the block, corrosion appears, causing it to break. This is one of the common problems.

Oil seeps through rotten metal. When such a block is disassembled, it breaks and cannot be restored.

It is better to entrust the replacement of auto parts to professionals who will carry out the replacement and pump it without violating the factory specifications.

The block is restored to normal condition. Specialists will carry out diagnostics, clean the device, process it, bring the wires out and install protection against sand, moisture and reagents, and make adjustments.

The correct approach to the Land Cruiser will extend its service life by more than one year.

Our car service specializes in the repair of transfer gearboxes, gearboxes (front and rear), all-wheel drive clutches, Haldex pumps, LED lights and electronic control units.