Tires and wheels are selected in accordance with the manufacturer's recommendations. The parameters of suitable products are given in the reference tables. However, to eliminate errors, you should study the algorithm of actions in detail. Correct Toyota Corolla bolt pattern is necessary for traffic safety and extending the service life of the car’s functional components.

Wheels for the car are selected in accordance with the manufacturer's recommendations.

About choosing wheels and tires for Corolla 120 and 150

The following parameters are called drilling or bolting of wheel rims:

- LZ - number of holes;

- DIA - hub diameter;

- ET — offset (distance from the central axis of the product to the surface of the mating plane);

- PCD is the size of the circle connecting the centers of the holes.

Suitable products guarantee an exact fit of the joined parts. The node balancing calculated by the designer is saved. The load on the suspension elements does not increase.

Compliance with the tires specified for the vehicle model is ensured.

Characteristics of the original

The standard marking is indicated as follows: 7Jx17 H2 ET50 5x114.3 D60. Example transcript:

- 7 — seat width of the disk in inches (7*25.4=177.8 mm);

- J - edge shape encoding;

- 17 - diameter in inches;

- H2 - structural bosses (hamps), providing reliable fixation of a tubeless tire;

- ET50 - offset 50 mm;

- 5x114.3 - 5 holes (LZ), located around a circle with a size of 114.3 mm (PCD);

- D60 is DIA = 60 mm.

Drilling for the E120 model (2000-2008 production) corresponds to the diagram:

- LZ - 4 pcs.;

- PCD - 100 mm;

- DIA - 40 mm;

- ET - 39-45 mm.

The standard equipment includes R14 tires.

Wheel parameters for Corolla E150 (2007-2012 production):

- LZ - 5 pcs.;

- PCD - 114.3 mm;

- DIA - 60.1 mm;

- ET - 39-45 mm.

Compatible tire sizes for this model: R15, 16 and 17.

Tires R15.

Wheel size table

To correctly select products, use the manufacturer’s reference materials:

| Model | Engine (power, hp) | Disc (ET) |

| E120 | 1.4 D (89) | 5.5Jx14 (45) |

| 1.4 VVT-I (95) | 5.5Jx14 (45); 6Jx15(39) | |

| E150 | 1.4 D-4D (89) | 6Jx15(39); 6Jx16(45) |

| 2.2 D-4D (125) | 6Jx15(39) |

The tabular data illustrates the need to take into account compatibility with the car model. In addition to the series, attention is paid to compliance with the engine size and type.

Selection of tires for cars

Wheel characteristics are selected in the same way. The dimensions of the tires must correspond to the mounting dimensions of the rim. On the other hand, contact of the wheel with the body arches should be avoided in all operating modes.

| Model | Engine (power, hp) | Tires |

| E120 | 1.4 D (89) | 175/70 R14 |

| 1.4 VVT-I (95) | 175/70 R14; 195/65 R15 | |

| E150 | 1.4 D-4D (89) | 195/65 R15 |

| 2.2 D-4D (125) |

Analogues of official products

If one disk is damaged and repair is not possible, you can contact a car dealer and purchase an original. However, such a solution is not always acceptable.

The manufacturer of components supplies its products for car assembly and supply to dealerships. However, it does not offer originals in its own line.

Taking into account the commercial profits of the automaker and resellers, the final price increases significantly. It is more profitable to purchase copies or other suitable models.

When choosing an alternative option, in addition to sizing, you should check:

- resistance of the structure to shock loads;

- protection from aggressive chemical compounds;

- compliance with the load, taking into account the total weight of the car, passengers, and cargo.

Experienced experts recommend buying disks from reliable manufacturers that have received positive ratings from experts and ordinary users. In addition to the affordable price, the advantage of analogues of official products is the expanded range. With such products you can improve the appearance of your car without extra costs.

Wheel sizes for Toyota Corolla

In recent generations, the Corolla has become very similar to the Camry, but in a shortened version. However, because of this, it did not become more crowded inside.

As for wheels for Toyota Corolla, there are not many variations here. Models with the same parameters are suitable for all generations:

- For 16 disks, the relevant parameters are 6.5x16 ET 45.

- For 17 inches - 8x17 ET 40, but the offset can be increased to 42.

- It is better to choose 15 inches with indicators 6x15 ET 39.

- If you like 18 wheel rims, then you should choose from those with parameters 7.5x18 ET 32.

The bolt pattern should be 5/114.3, but depending on the configuration it can be 4/100. This needs to be checked.

Wheel bolt pattern on Corolla

The technical parameters of products in this category should be assessed as a whole. To ensure they match the car model, wheels and tires are selected.

Required wheel parameters

Explanation of standard marking 160/70 R13 91T:

- width - 160 mm;

- profile height - 70% of 160 = 112 mm;

- cord design (R) - radial;

- landing radius - 13 inches;

- load (speed) index - 670 kg (190 km/h).

Select a wheel that matches the tire size. To simplify the assessment, you can focus on the products recommended by the manufacturer for the car. It is convenient to use a specialized calculator, which trading companies offer for free on their official websites.

Bolt pattern chart for different Corolla models

| Engine (series, year of manufacture) | Width x diameter in inches | LZxPCD (drilling), mm | DIA, mm | Reach (ET), mm |

| 1.3i (E100, 1995) | 5x13 | 4x100 | 54,1 | 39 |

| 2.2 D (E110, 1999) | 5×13 | 4×100 | 54,1 | 39 |

| 1.8 i (E110 - phaselift, 2002) | 5,5×14 | 4×100 | 54,1 | 45 |

| 1.8 VVT-I (E120, 2004) | 6×14 | 4×100 | 54,1 | 45 |

| 1.8 VVTL-i IX (E130, 2007) | 5,5×14; 6×15; 6×16; 7,5×17 | 4×100 | 45; 45; 45; 40 | 54,1 |

| 2.4 VVTi X (E140 - phaselift, 2011) | 7×17; 7,5×18; 7,5×18 | 5×100 | 39; 32; 42 | 54,1 |

| 2.0 D-4D X (E150 - phaselift, 2012) | 6×15; 6,5×16; 7×17; 7×17 | 5×114,3 | 39; 45; 45; 39 | 60,1 |

| 1.8i XI (E170, 2019) | 6×15; 6,5×16; 7×17 | 5×100 | 33; 39; 39 | 54,1 |

How is bolt pattern measured?

If there are 4 PCD holes, this parameter can be obtained without complex calculations. Use a ruler to measure the distance between the centers of opposite attachment points. The table shows the calculation algorithm for different initial conditions:

| Distance between centers of adjacent holes, mm | Number of bolts | Coefficient | PCD, mm |

| 120 | 3 | 1,155 | 120*1,155=138,6 |

| 140 | 4 | 1,141 | 140*1,141=159,74 |

| 150 | 5 | 1,701 | 150*1,701=255,15 |

The holes in the disk are made using an increasing tolerance. When choosing in a store, the risk of an erroneous assessment increases, because... a difference of 1-2 mm is difficult to notice. However, when fixing the fastener, misalignment provokes insufficient tightening of one of the bolts.

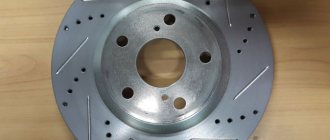

Samples of wheels for Toyota Corolla with bolt pattern.

Additional markers

Let's look at each of them. These values occur in random order, partially or all at once. And they may also be absent.

MAX LOAD

This is an index of the maximum permissible load on a single point. That is, not on the entire surface, but only on one wheel. Usually presented in pounds. To convert to our native kilograms, simply divide the indicated number by 2.2.

MAX PSI-50 COLD

Let's see what the numbers on the rims mean and how to decipher this type of marking. This option indicates the number of atmospheres inside the tire. As you can see, 50 PSI. But what are these units of measurement? To clarify, 1 kilogram-force equals 14 PSI. Accordingly, the parameter can be calculated by simple division. But we also see a small postscript that sounds like COLD. It is not difficult to translate and understand that measurements must be made at cold temperatures. After all, as you know, when heated, air expands, and the pressure will change accordingly.

FORGET

This short entry talks about the manufacturing method. The type refers to forged products.

BEADLOCK

Tire fixation. This technique did not pass the necessary safety checks, so the prototypes were withdrawn from sale.

BEADLOCK SIMULATOR

Now this is an interesting point. The sign says that a tire fixation simulator is being used. But in fact, such a simulation is no different from conventional models. That is, you can safely ignore this specific entry. Nothing bad will happen.

SAE/ISO/TUV

Many people wonder just the quality control systems that have been tested. An analogue of GOST or TU known in the Russian Federation. By the way, you can also meet them at certification sites. In principle, the presence of such markers only increases the level of trust in the product, because the manufacturer has taken care of some form of guarantor. But the question of where the markings are located on cast and stamped discs remains open. After all, there is no specific place to indicate the certification stamp; the manufacturer himself chooses where to place it.

Date of manufacture

It is indicated in a non-standard form. Therefore, many people confuse it with something else. After all, instead of the usual date and month, we see the week number. Alternatively, 10. Tenth week from the beginning of the year. You'll have to do a little math. But the last two digits are already the year - 21 for modern goods.

A country

Full name, logo or abbreviation. Everything remains at the discretion of the manufacturer. As well as the need to apply such information.

The importance of following factory recommendations

With a slight deviation of the landing dimensions, the difference in the bolt pattern of the Toyota Corolla wheels is not determined visually. But in this situation, after tightening one bolt, other fasteners move. An imbalance initially provokes a slight beating, causing discomfort. Subsequently, components of the steering, suspension, and braking system are destroyed. Such impacts create emergency situations and reduce the life of valuable components and assemblies.

If the DIA is smaller than the standard diameter, the disc will not fit on the protruding part of the hub. If the hole is too large, similar obstacles will not arise during the installation process. However, you will have to install an additional ring for accurate alignment.

Moving the offset towards the widening (narrowing) of the track:

- worsens handling when cornering;

- accelerates bearing wear;

- creates additional load on the suspension;

- increases the risk of tires contacting body parts.

In the same way, the tires are checked for compliance with the manufacturer’s recommendations.

How are alloy wheels marked?

In principle, there are no key differences. But there is one important factor that should not be overlooked. In addition to the standard data, the casting must always have a certification mark, which is applied after checking with a special x-ray. There is also a label of the organization responsible for the procedure. Usually this is not a manufacturer, but a company that has the appropriate license.

Tips for carrying out bolt removal yourself

Even minor deviations in size can cause breakdowns and emergency situations. To eliminate errors, the results of personal measurements are checked against the manufacturer’s reference data. Please note that there are no markings on the original stamped discs.

For small errors, to compensate for PCD, car enthusiasts use longer screws or do not fix one fastener. Such actions provoke accidents. Instead of such solutions, you can use special bolts with an offset central axis. To achieve size matching, bore the mounting hole.

If the vehicle owner finds it difficult to determine the technical parameters, it is necessary to contact the dealer for professional advice. An experienced manager in a specialized store will select a disk without errors. When making your own choice, you should be guided by the official recommendations of the car manufacturer.

Marking of stamped discs, decoding

But in this case there is no additional information. Completely standard entries, discussed in detail above. But both options may well contain additional information. And it is already able to provide more information, which, if it does not make a fundamental difference, can tell the consumer much more about the product.

Japanese wheels

There are two types of markers that are atypical for Russian consumers. JWL, certificate from the Japanese Ministry of Transport. The requirements imposed in the country are very high and are aimed exclusively at the domestic market. But any manufacturer in the world can apply and pass the test using the Japanese system. In this way, he will be able to prove to his client that his product meets the Japanese quality expectations. And they are known to be very demanding in this area.

The VIA marker also indicates the level. This is not an analogue of the first one, but simply an icon of completed additional tests. Basically, the topic of the review: marking of car wheels and tires on cars and decoding of the symbols. And Japanese markers belong here indirectly; in our country, as well as in Europe, there are almost none of them. But we included them because this is direct evidence that the product was produced at the highest level available today. And there’s definitely no point in doubting him.