Error P0354-P0351 and coil tip ground (Corolla 150)

I was driving home from work, everything was as usual, and then the CHECK popped up and the “check engine” sign appeared on the board.

At this moment, the car jerked, as if it was stalling, and then it seemed to be running smoothly again, but the check light was on and asked to check the engine. Naturally, I go out and check that “the engine is in place”, it’s already good))) I looked at all the crap in the oil, nothing was running around dryly, and I drove on. I read on the Internet they write different things, in general you need to check what’s wrong with a scanner, it’s good that a good person has such a gadget at work. The check shows that the cause is the ignition coil in the fourth cylinder “D”. I start looking for prices, it turns out the original starts from 5 thousand rubles. and Chinese analogues can be purchased for 2 thousand rubles. In short, I decided to rearrange it with the coil of the first cylinder and further make sure.

I've been driving like this for a couple of days, no errors, I'm kind of glad, although I know it will come out again. And so it happened, after a couple of days the “check engine” message flies out again, the next day I agreed to check it again with a scanner.

The check showed that the error in the coil of the first cylinder “A”, accordingly, passed with the replacement of the coils. There is only one conclusion that the reel is ruined. But at the same time, there are no hints of uneven operation of the engine, or for trouble, I read on the Internet about the tip on the coil that can deteriorate and that it can be replaced, in fact, that’s what I decided to do, since I don’t want to buy a whole coil, and especially a Chinese one . It’s better to let my dear one stand. I found the site nak-kat.ru and read it, the reviews are not bad. I ordered a tip for 300 rubles (one for testing, if I replace everything well and the rest) and Teflon grease for 50 rubles so that the tip does not remain in the well on the spark plug.

It turned out that the person who produces it lives at the next metro station from me, so a couple of days after the order he picked it up himself. The tip is not bad, the rubber seems to be of high quality, but time will tell)))

Replacement is simple: remove the old tip using a screwdriver and carefully pick it up.

There was factory sealant, I also cleaned it with a screwdriver, applied a little sealant to the new tip, everything dried and put it in its place.

I put everything in place. So far the error does not appear, time will pass and it will be clear whether I did it correctly or not. If everything goes well, I will replace the others because... When replacing it, I squeezed the old one and yet it had already served its purpose; when squeezed, it became full of cracks. And most likely, because of these cracks, the error occurred when the speed jumped on the body and an error was thrown, in theory)) with the new tip everything will be fine))

Source

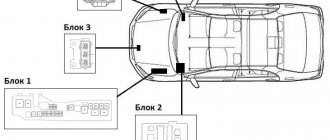

Toyota Corolla ignition system

The Corolla is equipped with two types of ignition systems: with an external and internal electronic unit.

Toyota Corolla ignition system. Photo source: https://fielder-toyota.ru/electrician3.html

They differ in the location of the switch.

How does the Toyota Corolla ignition system work?

The design of the ignition system of the Japanese car Toyota Corolla E100 from 1996 to 1997:

- egnition lock;

- accumulator battery;

- sensor-distributor;

- transformer;

- crankshaft position sensor;

- ignition module;

- engine control module;

- chain of low-voltage wires;

- high voltage wires;

- candles.

The ECM module receives information from sensors that determine the temperature of the power unit, crankshaft speed, and intake air mass. Based on these readings, the module provides accurate ignition setting.

Differences in ignition systems between different Toyota models

From 1998 to 2000, Toyota installed a distributorless ignition, which consists of a camshaft sensor, a crankshaft sensor, two coils for 4 cylinders and an ECM module.

The sensors provide a signal to the ECM, then voltage goes to the converter. For every 2 cylinders, one coil (1-4, 2-3) with high-voltage wires is used.

From one coil there are 2 wires for 2 spark plugs. A spark is produced in both cylinders, but only one of them undergoes the compression cycle.

Ignition coil for Corolla. Photo source: https://motorland.by/auto-parts/toyota/corolla/verso-2002-2004/

The 2001-2002 model was equipped with a DIS ignition system, which consists of camshaft and crankshaft sensors and spark plugs. The last element is equipped with a coil and a module connected to each other.

To find out how many ignition coils there are in a Corolla, just count the number of spark plugs. In this system, sparking occurs in the cylinder precisely at the moment when the compression stroke occurs.

All 2002 station wagon models based on the Corolla were called Toyota Fielder. The first generation Fielder was equipped with left-hand drive.

Weaknesses of Toyota Corolla ignition coils

The ignition coil of the Toyota Corolla E150, Toyota Verso, as on the E120, is a vulnerable and “capricious” part. Often a part fails due to insulation breakdown, overheating and winding burnout. Damage to the coil greatly affects the ignition system and engine:

- the engine starts with difficulty or stops starting at all;

- the power unit operates unstably: it troits and stalls;

- not setting the ignition leads to detonation, which will accelerate engine wear or lead to breakdown.

A faulty coil can create electromagnetic interference that disrupts the operation of all electrical systems in the vehicle.

How to determine if a Toyota Corolla ignition coil is faulty

If your 2008 Toyota Corolla displays an error message, you need to check the engine, ignition assembly, and coil.

Ignition coil under the hood. Photo source: https://www.drive2.ru/l/464584070861422613/

To find out which element has failed, you need to:

- inspect for cracks;

- start the engine and disconnect the plugs from the coils one by one: if changes occur in the operation of the engine, this indicates the serviceability of the part, but if the power unit operates without changes, then this voltage converter is damaged.

- remove the tip from the spark plug, insert a spare new spark plug into it, press the element body with the threads to the engine block and start the engine for a short time to check sparking.

There are cases when, when the ignition module fails, the Check engine error does not appear.

Checking ignition coils with a multimeter on a Toyota Corolla

Checking the ignition coils using a multimeter on a Toyota Corolla and Verso is carried out in the following way:

- It is necessary to disconnect the connectors and high voltage wires.

- Clean the outlet for good contact.

- Connect the device to the + and – contacts, as well as the primary winding contacts. The result should be 0.4-20 Ohm. Zero resistance indicates a short circuit, while high resistance indicates a possible open circuit.

- Then we check the secondary winding: connect the black wire to the output of the converter, the red wire to the positive. Indicators should be within 6-15 kOhm. The resistance should be the same on all 4 transformers. A discrepancy will indicate a break in the wiring.

Some service stations have special stands for checking the unit.

Reasons for coil failure

The reasons for failure of the ignition unit may be the following factors:

- Overheating of the power unit. When the unit heats above 150 degrees, the winding will burn out.

- If, with the engine off and the ignition on, the power source transmits 12 V to the coil, the winding will overheat and burn out.

- Damage to wiring.

- When spark plugs or armor wires wear out, despite the resistance limiter, insulation breakdown may occur. The load current will increase and overheat the bobbin.

- Oxide on contacts. Poor quality materials, constant humidity, chemical solutions from roads, temperature fluctuations, or simply poor contact lead to oxidation of armored wires.

- Vibration of the power plant can lead to broken contacts.

- Natural wear of the part. The service life of the transformer ranges from 60 to 80 thousand km.

If the module is damaged, an urgent replacement of the component is necessary, otherwise the entire electrical system of the car becomes vulnerable.