For the production of brake discs used on cars of this modification, high-quality high-carbon steel is used, which allows the product to better maintain its technical and operational characteristics not only during periods of exposure to high temperatures, but also during periods of sudden temperature changes.

In addition, the unique design of brake discs for the Toyota Camry 40, expressed in the presence of a system of internal ventilation ducts, ensures the most efficient heat removal.

For the same purpose, the vast majority of manufacturers successfully use product perforation technology, which consists of making through holes perpendicular to the working surface. An additional function of the perforations is to guarantee uniform wear of the pads and timely removal of road dirt, dust, moisture and wear products of friction linings from the working elements of the unit.

A high-quality paint coating protects brake discs from the harmful effects of corrosion.

Repair of the front wheel brake mechanism of a Toyota Camry

REMOVAL OF BRAKE PADS

When replacing brake pads, always replace the inner shims, outer shims, and shim caps as a set.

Drain the brake fluid.

Remove the front wheel and temporarily secure the rim with two nuts.

Unscrew the bolt and disconnect the brake hose bracket.

Rice. 1. Loosening the caliper bolts

Holding the guide pins, unscrew the caliper mounting bolts (Fig. 1).

Lift the caliper and secure it with wire.

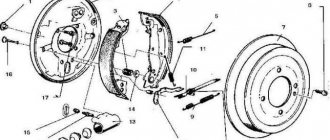

Rice. 2. Brake pad components: 1 – anti-squeak plate; 2 – anti-creaking gasket; 3 – brake pads; 4 – pad wear indicators

Remove two anti-squeak springs, two brake pads, two anti-squeak pads holding the plate liners (Fig. 2).

Rice. 3. Removing pad wear indicators

Using a thin blade screwdriver, remove the pad wear indicators (Fig. 3).

Rice. 4. Removing the guide pins from the caliper

Remove the guide pins from the caliper (Fig. 4).

Rice. 5. Removing the O-ring from the guide pin

Using a thin blade screwdriver, remove the O-rings from the guide pins (Fig. 5).

When removing the seal, be careful not to damage the guide pin housing.

Rice. 6. Removing the caliper

Unscrew the caliper housing mounting bolts and remove the caliper (Fig. 6).

Rice. 7. Removing the guide pin anthers

Holding the caliper in a vice with soft jaws, use a screwdriver and hammer to remove the guide pin boots (Fig. 7).

Rice. 8. Removing the brake cylinder cover

Using a screwdriver, remove the brake cylinder boot spring ring and boot (Fig. 8).

Place a rag between the piston and cylinder.

Rice. 9. Removing the piston from the cylinder

Using compressed air, remove the piston from the cylinder (Fig. 9)

Rice. 10. Removing the oil seal

Using a screwdriver, remove the oil seal (Fig. 10).

CHECKING THE BRAKE PADS

Rice. 11. Measuring the thickness of brake pads

Measure the thickness of the brake pads with a ruler (Fig. 11).

Standard thickness: 12 mm.

Minimum thickness: 1.0 mm.

CHECKING THE BRAKE DISC AND BRAKE COMPONENTS

Check for corrosion, wear and damage on the inner cylinder walls.

Replace the cylinder body if necessary.

Minor imperfections caused by corrosion or foreign particles can be removed by sanding the surface with fine emery cloth.

Replace the cylinder body if necessary.

Check for wear, cracks and damage.

Replace the relevant component if necessary.

Check for corrosion, wear and damage on the piston surface.

Replace the relevant component if necessary.

Check the guide pin and guide pin boot for corrosion, wear and damage.

Replace the relevant component if necessary.

Check the surface of the brake rotor for uneven wear, cracks or serious damage.

MEASUREMENT OF BRAKE DISC THICKNESS

Rice. 12. Brake disc thickness measurement

Using a micrometer, measure the thickness of the brake disc (Fig. 12).

Standard thickness: 28 mm

Minimum thickness: 26 mm

Replace the disc if the disc thickness is less than the minimum permissible thickness.

BRAKE DISC RUN-OUT MEASUREMENT

Rice. 13. Marking the hub axle bushing and brake disc

Place marks on the brake disc and wheel hub axle bushing (Fig. 13).

Secure the brake disc to the wheel hub using wheel nuts (in 2 places or more).

Rice. 14. Checking disk runout using an indicator

Check the runout with an indicator (Fig. 14).

Measuring point: 10 mm from the outer edge of the disc. maximum runout: 0.05 mm or less.

Before taking measurements, make sure that the end play is 0 mm.

If the runout is significant, find the point of minimum runout by sequentially shifting the installation position of the brake disc on the hub by one hole.

Rice. 15. Installing the seal in the piston

Apply lithium rubber grease to the piston seals and install them into the cylinder body (Figure 15).

When installing, do not use too much force to avoid damaging the parts.

Rice. 16. Installing the spring ring and brake cylinder boot

Install the brake cylinder boot spring ring and boot (Fig. 16).

Removing, replacing, installing front wheel brake pads

Directory

Tags

Removing, replacing, installing anti-roll bar

Removing, replacing, installing timing belt

Removing, replacing, installing rear suspension shock absorber spring

Inspection, checking the steering

Removal, replacement, installation of the crankshaft and its bearings

Symptoms: braking efficiency has decreased.

Possible cause: the brake pads of the brake mechanism are worn out.

Tools: socket set, hex set, flat blade screwdriver, Phillips screwdriver.

Note. Measure the thickness of the friction linings of the brake pads (minimum permissible thickness is 2 millimeters), and also inspect the pads for oiliness, weak connection of the linings to the metal base, deep scratches, grooves, marks and chips. If one of the above defects is detected, replace the pads with new ones.

Remember that brake pads must be replaced exclusively in a set of four: two pads for the brake mechanism of each wheel.

1. Loosen the tightening of the wheel mounting bolts on the side of the brake pads being removed from the wheel brake mechanism.

2. Install wheel chocks under the front wheels.

3. Raise the car with a jack and place it on a reliable and strong support.

4. Remove the front wheel from the brake pad side by completely removing its mounting bolts.

Note. Loosening and final tightening of the wheel mounting bolts is carried out only with the vehicle placed on the ground with all wheels.

5. Insert a large screwdriver between the inner brake shoe and the front brake wheel piston, and then press the piston into the cylinder.

6. Unscrew the lower guide pin of the wheel brake caliper.

7. Remove the unscrewed guide pin from the hole located in the pad guide.

8. In the same way, unscrew and remove the second guide pin of the brake caliper.

9. Remove the caliper from the guide without disconnecting the hose. Make sure that the brake hose is not kinked, twisted or over-stretched.

10. Remove the springs.

11. Remove the brake pads of the wheel brake mechanism.

Note. Pay attention to the brake pad markings. For replacement, purchase only pads with identical markings.

Helpful advice. Whenever you replace the brake pads of the wheel brake mechanisms, be sure to check the condition of the protective plastic bushings of the caliper guide pins, and also check the movement of the caliper relative to the guide pads. If movement is difficult, apply grease to the brake caliper guide pins. If the guide pin protective bushings are damaged, replace them.

12. Check the brake pads for defects and signs of wear.

13. Install new brake pads in the reverse order of removal. Prevent spontaneous unscrewing of the wheel brake caliper guide pins by lubricating their threaded part with an anaerobic thread locker.

14. Place the brake pads on the brake disc by pressing the brake pedal several times.

15. Install the removed front wheel.

16. Replace the brake pads of the other wheel using the same method.

17. Check and restore, if necessary, the brake fluid level in the system.

Helpful advice. Take your time on busy highways and roads immediately after replacing your brake pads. Perhaps the very first intense braking will greatly disappoint you due to its low efficiency. Brake discs also wear out, and therefore new brake pads adhere to them only at the edges, practically without braking. Select a quiet street or driveway with little or no traffic, and then apply the brakes gently several times. This is necessary so that the brake pads get used to the surfaces of the brake discs of the front wheels and begin to adhere to them with their entire working area.

How to change brake discs on a Toyota Camry v40

You will be able to like, write comments and subscribe to channels.

View Queue

Queue

- delete everything

- Disable

By download date

Duration

Peculiarities

Arrange

- By relevance

- By download date

- By number of views

- By rating

Replacing brake discs and pads - nuances (Toyota Camry) - Duration: 12:11

- 1 year ago

- 7,243 views

Replacing front brake discs on a Toyota Camry – Duration: 15:58

- 6 months ago

- 1

How to change brake discs and pads on a Toyota Camry V50. Toyota Camry V50. – Duration: 13:20

- 2 years ago

- 13

REPLACING BRAKE DISCS FOR TOYOTA CAMRY 2008. 3.5 V40 – Duration: 3:25

- 2 years ago

- 8

Toyota Camry v 40 how to change brake pads yourself | Auto life hacks – Duration: 7:52

- 3 years ago

- 18,494 views

Toyota Camry 40 front brake pad replacement review – Duration: 6:54

- 4 years ago

- 17

BRAKE DISCS | REPLACEMENT TIMELINES | DIAGNOSTICS – Duration: 3:49

- 4 years ago

- 93

HOW TO CORRECTLY REPLACE BRAKE DISCS FOR A TOYOTA KAMRY V30 – Duration: 13:01

- 3 years ago

- 12

Replacing brake discs on a Camry 40. Toyota Camry v40 – Duration: 2:47

- 2 years ago

- 3

Replacing front brake pads on a Toyota Camry 50 – Duration: 10:39

- 2 years ago

- 21

Toyota Center Lyubertsy. LC200. LC150. LC120. Replacement of front brake discs. – Duration: 4:43

- 2 years ago

- 28,861 views

replacing front brake discs and pads Toyota Camry 30 40 50 – Duration: 1:50

- 4 years ago

- 8,462 views

Articles

To replace Camry 70 brake pads with original ones, use the following catalog numbers of spare parts manufactured by TOYOTA/LEXUS:

- 0446533480 – front for Toyota Camry 70 models;

- 0446633220 – rear.

Analogues are also available for the Camry 70, their article numbers are:

- 43KT – KOTL company;

- NP1167 – NISSHINBO;

- 0986-4948-33 – BOSCH;

- 2276-801 – TEXTAR;

- PN1857 – NIBK.

- D2349 – KASHIYAMA;

- NP1112 – NISSHINBO;

- 2243-401 – TEXTAR;

- PN1854 and PN1854S – NIBK;

- 1304-6056-932 – ATE;

- 182262 – ICER;

- 8DB3-5502-5121 – HELLA.

Recommendations based on your search history

Which brake pads are best for AUTO – Duration: 14:39

- 1 year ago

- 461

What the Camry suspension DOES! Comparison with KIA Optima 2021 – Duration: 25:52

- 1 year ago

- 1 164

The cost of a mistake is 700,000 rubles - DO NOT REPEAT. – Duration: 11:49

- 3 years ago

- 4,601,171 views

Camry 50 “Three Olgas” Episode 7. WATCH FOR EVERYONE. Adjusting the handbrake. About the brakes. – Duration: 20:35

- 1 year ago

- 18

What kills brake discs? Choosing pads – Duration: 20:26

- 3 years ago

- 243

Beating and vibration when braking. What is the reason? – Duration: 4:22

- 2 years ago

- 1 444

Grooving brake discs - SAVE A LOT OF MOUNTAIN! Simply about the complex – Duration: 18:16

- 2 years ago

- 577

Why brake pads squeak - 6 MAIN REASONS - Duration: 7:39

- 2 years ago

- 519

Drilled or slotted brake discs - Duration: 5:55

- 1 year ago

- 14

Is the brake pedal hitting? Are the brake discs worn? Don't rush to sharpen! Watch this video first! – Duration: 24:57

- 1 year ago

- 142

- Subtitles

Replacing the front brake pads of a Toyota Camry XV50 Toyota Camry 2012, 2.5 – Duration: 10:38

- 1 year ago

- 4

Replacement of front brake pads of Toyota Camry XV50 Toyota Camry 2012, 2.5

Thank you for your views and for your subscription.

Queries similar to replacing front brake discs for Toyota Camry 40

toyota camry replacing brake pads – Duration: 8:23

- 8 months ago

- 341 views

DO NOT BUY ORIGINAL BRAKE PADS UNTIL YOU WATCH THIS VIDEO – Duration: 3:58

- 2 years ago

- 51,904 views

Front brake disc TOYOTA CAMRY (V40-V50), RAV4 III-IV, AURIS art.DF4828S – Duration: 2:03

- 3 years ago

- 3,652 views

Toyota Camry 40 | KILLED THE BRAKE DISCS – Duration: 6:19

- 4 months ago

How to change brake discs on a Toyota Camry v40

You will be able to like, write comments and subscribe to channels.

View Queue

Queue

- delete everything

- Disable

By download date

Duration

Peculiarities

Arrange

- By relevance

- By download date

- By number of views

- By rating

Replacing brake discs and pads - nuances (Toyota Camry) - Duration: 12:11

- 1 year ago

- 7,243 views

Replacing front brake discs on a Toyota Camry – Duration: 15:58

- 6 months ago

- 1

How to change brake discs and pads on a Toyota Camry V50. Toyota Camry V50. – Duration: 13:20

- 2 years ago

- 13

Toyota Camry v 40 how to change brake pads yourself | Auto life hacks – Duration: 7:52

- 3 years ago

- 18,494 views

REPLACING BRAKE DISCS FOR TOYOTA CAMRY 2008. 3.5 V40 – Duration: 3:25

- 2 years ago

- 8

Replacing brake discs on a Camry 40. Toyota Camry v40 – Duration: 2:47

- 2 years ago

- 3

Toyota Camry 40 front brake pad replacement review – Duration: 6:54

- 4 years ago

- 17

HOW TO CORRECTLY REPLACE BRAKE DISCS FOR A TOYOTA KAMRY V30 – Duration: 13:01

- 3 years ago

- 12

BRAKE DISCS | REPLACEMENT TIMELINES | DIAGNOSTICS – Duration: 3:49

- 4 years ago

- 93

Replacing front brake pads on a Toyota Camry 50 – Duration: 10:39

- 2 years ago

- 21

Toyota Center Lyubertsy. LC200. LC150. LC120. Replacement of front brake discs. – Duration: 4:43

- 2 years ago

- 28,861 views

Replacing the front brake pads of a Toyota Camry XV50 Toyota Camry 2012, 2.5 – Duration: 10:38

- 1 year ago

- 4

Replacement of front brake pads of Toyota Camry XV50 Toyota Camry 2012, 2.5

Thank you for your views and for your subscription.

How to spot a fake

When you buy premium brake discs, you don’t want to be deceived and pay money for the wrong quality. Most often, counterfeits are made with expensive spare parts, and in order to avoid getting into trouble, let’s look at how to distinguish a counterfeit from an original using the example of premium ATE wheels.

| Fake | Original |

| The packaging is rich, glossy, blue | |

| The lid of the package is not glued | The package lid is glued |

| The lid is packed in a bag | The lid is sealed |

| There may be trash inside | Perfectly clean inside |

| Stickers are missing | Protective sticker Tesa Priospot |

| No codes or hologram | Mapp code, the last digits of which coincide with the hologram |

Recommendations based on your search history

What the Camry suspension DOES! Comparison with KIA Optima 2021 – Duration: 25:52

- 1 year ago

- 1 164

Which brake pads are best for AUTO – Duration: 14:39

- 1 year ago

- 461

The cost of a mistake is 700,000 rubles - DO NOT REPEAT. – Duration: 11:49

- 3 years ago

- 4,601,171 views

Camry 50 “Three Olgas” Episode 7. WATCH FOR EVERYONE. Adjusting the handbrake. About the brakes. – Duration: 20:35

- 1 year ago

- 18

Grooving brake discs - SAVE A LOT OF MOUNTAIN! Simply about the complex – Duration: 18:16

- 2 years ago

- 577

What kills brake discs? Choosing pads – Duration: 20:26

- 3 years ago

- 243

Why brake pads squeak - 6 MAIN REASONS - Duration: 7:39

- 2 years ago

- 519

Beating and vibration when braking. What is the reason? – Duration: 4:22

- 2 years ago

- 1 444

Is the brake pedal hitting? Are the brake discs worn? Don't rush to sharpen! Watch this video first! – Duration: 24:57

- 1 year ago

- 142

- Subtitles

How to press in the rear caliper piston. Two ways. – Duration: 5:36

- 4 years ago

- 1 405

DO NOT BUY ORIGINAL BRAKE PADS UNTIL YOU WATCH THIS VIDEO – Duration: 3:58

- 2 years ago

- 51,904 views

Queries similar to replacing front brake discs for Toyota Camry 40

replacing front brake discs and pads Toyota Camry 30 40 50 – Duration: 1:50

- 4 years ago

- 8,462 views

toyota camry replacing brake pads – Duration: 8:23

- 8 months ago

- 341 views

Toyota Camry 40 | KILLED THE BRAKE DISCS – Duration: 6:19

- 4 months ago

Additional Information

Fans of a sporty driving style, as well as adherents of aggressive driving, can recommend brake discs from the DBA campaign, manufactured using Thermal Stability Profiling technology, which provides the following operational advantages:

- The unique structure of the material ensures the resistance of the working surface to the effects of deformation processes.

- Immunity to the effects of sudden (prolonged) braking.

- Quick “grinding in” of working surfaces.