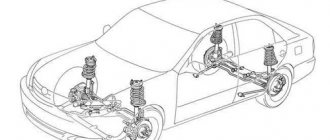

Toyota Corolla has eleven glorious generations of cars, which have been released from 1966 to the present day. It makes no sense to consider brake pads for all these generations and modifications, since at most three generations (including restylings) remain relevant. Therefore, the following will be considered:

It is worth noting here that over time, the rear brakes of the Toyota Corolla changed from drum to disc. So on some 9th generation sedans, before restyling, drum brakes were still found, and after restyling, they were already disc brakes. In the 10th generation, with the exception of some models poorly represented on the Russian market, only disc brakes were found. Just like on the 11th generation Corolla.

What kind of brake discs to put on Toyota

For example, Toyota Corolla owners prefer to install wheels from the following manufacturers: ATE, Brembo, TRW. Brakes from DBA, Zimmermann, and Brembo brands are suitable for Toyota Camry. Owners often choose premium class brakes, less often the mid-price segment. Let's look at the advantages of some brands over others.

Allied Nippon

Best Quality Country: Japan Rating (2020): 4.9

For several years in a row, Allied Nippon has received the well-deserved title of the leading manufacturer of brake systems around the world. Needless to say, the company’s arsenal is very large. Here you can find both pads for native Japanese or Korean cars (Honda Accord, Hyundai Solaris, etc.), as well as designs for the domestic VAZ (Priora, Kalina) and a number of European cars.

The entire line of brake pads is tailored to the urban rhythm - they can easily withstand a mixed driving cycle, accompanied by constant acceleration and sharp braking, thanks to the use of mineral metallic technology - ferrocarbon. However, the main advantage lies in the composition of the friction linings. The unique asbestos-free mixture NAM114 has a long service life and, according to this indicator, is capable of leaving analog developments from other manufacturers out of business.

Advantages:

- Availability of brake pads for domestic cars (VAZ and GAZ);

- the product is excellent for mixed driving;

- the pads can withstand short-term overloads and dissipate heat well;

- asbestos-free clutch and Ferro Carbon technology.

Flaws:

- usually high cost.

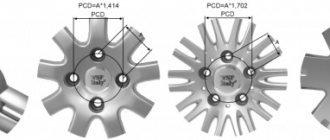

How to choose the right brake disc

The choice of wheels depends on the vehicle's power and driving style. If you have a herd of horses under the hood and a thirst for speed in your blood, then you should think about the most efficient brakes with ventilation, notches and perforations. If you are a calm driver who drives according to the rules and does not like to press the pedal to the floor, then there is no point in expensive, sophisticated brakes. Simple ventilated discs will do.

Description of caliper repair for Corolla 150

Torn brake piston boot

During the operation of the car, the caliper boots are destroyed. In order not to carry out an expensive replacement, the car owner has the opportunity to purchase a special kit and make repairs.

New rubber cuffs

When replacing a torn boot, you must first put it a little on the piston, and then on the cylinder. If you reassemble in the reverse order, there is a high risk of breaking the rubber.

Boot installation process

Completing the boot replacement

The caliper is constantly exposed to aggressive environmental influences. Because of this, a layer of corrosion forms on its surface. It can be cleaned using a metal brush and special tools.

When repairing a caliper, lubrication of the guides is mandatory. In this case, information about heat resistance must be indicated on the tube. Otherwise, the lubricant will be destroyed when the brakes first heat up and the guides will jam.

Premium brake discs

Premium brake spare parts on the auto parts market are represented by the following brands:

- Otto Zimmermann - have the highest wear resistance of the presented

- ATE – highest quality

- DBA – the most technologically advanced of those presented

- FREMAX – excellent value for money

- EBC manufacturability, wear resistance, quality. No. 1 brand in the premium brake segment.

Description of replacing calipers on Corolla 150

You can replace the calipers on the Corolla 150 using the instructions below.

- Jack up the car.

- Remove the wheel.

- Turn the steering wheel all the way. This will make it easier to remove the caliper.

- Clamp the brake circuit hose to prevent fluid leakage and air in the system.

- Unscrew the caliper mount.

- Install in the reverse order of removal.

Inexpensive brake discs

In the budget segment, the list of manufacturers looks like this:

- Ferodo – quality and wide selection of models

- NiBK – price-quality ratio

- Bosch - of those presented have the best price

- Avantech – provide low vibration levels

- Nipparts – average quality, average price

ATE

Best range of brake pads Country: Germany Rating (2020): 4.5

A German giant in the production of brake systems, dating back to 1958. As in ancient times, innovation and the pedantry inherent in the Germans are the fundamental concept for the production of pads, which are in consistently high demand among Russian car enthusiasts. The supported models include not only European cars: here you can find pads for Solaris, and for Kia Rio, and even for the brainchild of the notorious General Motors - the Chevrolet Lacetti and the Russian American Chevrolet Niva.

In the manufacture of an important element of the brake system, wear-resistant hard alloys of titanium, chromium, nickel, etc. are used, which guarantee longevity and excellent performance of their direct duties. But the main asset of the company is ceramics - silent ceramic pads are widely used in supercars.

Advantages:

- a company with a rich production history and extensive experience;

- use of new production technologies in pads;

- a large number of supported car models.

Flaws:

- consistently high cost.

How to spot a fake

When you buy premium brake discs, you don’t want to be deceived and pay money for the wrong quality. Most often, counterfeits are made with expensive spare parts, and in order to avoid getting into trouble, let’s look at how to distinguish a counterfeit from an original using the example of premium ATE wheels.

| Fake | Original |

| The packaging is rich, glossy, blue | |

| The lid of the package is not glued | The package lid is glued |

| The lid is packed in a bag | The lid is sealed |

| There may be trash inside | Perfectly clean inside |

| Stickers are missing | Protective sticker Tesa Priospot |

| No codes or hologram | Mapp code, the last digits of which coincide with the hologram |

Article number and cost of original Corolla 150 calipers and their analogues

Article numbers and approximate costs for new original calipers are shown in the table below.

Table - Branded calipers Corolla 150

| Location | Article number | Estimated cost, thousand rubles |

| Front right | 4773012A10 | 01.10.1932 |

| Front left | 4775002340 | 01.10.1932 |

| Rear right | 4783002100 | 01.08.2016 |

| Rear left | 4785002100 | 01.08.2016 |

Since the cost of original calipers is quite high, many car owners give preference to third-party manufacturers. Lists of the best brands are given in the tables below.

Table - List of analogues of the branded front right caliper Corolla 150

| Company manufacturer | Article number | Cost, ruble |

| N.K. | 2145278 | 2400-300 |

| TRW | BHS1109E | 7500-9000 |

Table - List of analogs of the original front left caliper Corolla 150

| Brand | Article number | Cost, ruble |

| MSG | TY6152R-L | 3500-4500 |

| Apec Braking | LCA688 | 4800-6000 |

| Budweg Caliper | 344236 | 2300-3400 |

| Brake Engineering | CA2960 | 2500-3900 |

| FTE | RX5798151A0 | 4000-6000 |

Table - List of analogues of the original rear right caliper Corolla 150

| Company manufacturer | vendor code | Cost, ruble |

| Elstock | 872101 | 4600-5500 |

| Lauber | 772805 | 3900-7600 |

| Bosch | 986135054 | 6500-8900 |

| ABS | 624082 | 6600-8500 |

| Febest | 0177ADE150RRH | 5200-6500 |

Table - List of analogues of the original rear left caliper of Corolla 150

| Company manufacturer | Catalog number | Cost, ruble |

| Elstock | 862101 | 4600-5200 |

| Bosch | 986134054 | 6200-6700 |

| ABS | 624081 | 6700-7900 |

| Febest | 0176ZRE151RKIT | 2400-2800 |

| N.K. | 2145259 | 11000-13500 |

In addition to replacement, you can restore the performance of the brake system if the caliper fails by repairing it. For these cases, Toyota produces original repair kits, the article numbers of which are:

- front - 0447802160;

- rear - 0447912230.

The cost of the front repair kit is 1400-4000 rubles. For a branded rear caliper repair kit, the car owner will need to pay from 1,200 to 3,400 rubles. Third party manufacturers also produce repair kits. For the front caliper, car owners recommend using exclusively the Febest kit. It produces its products for the Corolla 150 with article number 0175ZRE151F and costing 500-900 rubles. The list of the best repair kits from third-party manufacturers for the rear caliper is given in the table below.

Table - List of analogues of the rear caliper repair kit for Corolla 150

| Company manufacturer | Catalog number | Price, ruble |

| ERT | 401601 | 180-250 |

| Autofren | D41626 | 320-380 |

| Febest | 0175ZZE150R | 450-520 |

| Frankit | 238063 | 205-225 |

9: Bosch

Brake pads for foreign cars from Bosch occupy ninth position in the ranking of the best. They contain about 20 components. Approximately 20% are binders: artificial resins and natural rubber. Steel copper, zinc, bronze, aluminum - 10%. Carbon fiber, synthetic fibers and mineral wool make up about 10%. The fillers used are AL and FE oxides and approximately 25% Na sulfate. 35% are components of the form: graphite, Cu and Al sulfides. The BOSCH product line meets the stringent requirements of automakers for uniformity and stability of characteristics, vehicle behavior at high speeds, wear resistance, and fretting.

Brembo

This Italian manufacturer develops elements of brake systems for sports cars and industrial sports cars. The brand's consumables are actively used by the legendary Ferrari. The Brembo pad catalog contains more than 1.5 thousand items, and all models of manufactured auto parts comply with ECE R90. At least half of the brake components developed by Brembo are suitable for aggressive driving.

The Brembo Xtra concept is also worth considering. These brake pads are made for sports cars, but are also distinguished by comfort and safety. The good performance qualities of the linings are explained by their composition, which is based on the innovative material BRM X L01. This substance was created by the company from 30 components after careful research and testing. Linings made of this material have minimal dust emission with a high coefficient of friction and wear resistance. Thus, brand consumables usually last at least 150 thousand km.

Advantages:

- Production of pads for sports cars and aggressive driving;

- Assortment of 1500 items corresponding to ece r 90;

- Introduction of unexpected concepts;

- High production standards.

BLITZ

Consumables of this brand are installed on cars from almost all well-known manufacturers. Additional expansion of the range of brake pads is aimed at cars from the Japanese and South Korean markets, but partly also at European cars.

A special feature of the brand’s consumables is the lapping layer, which was created according to the recommendations of German engineers. The manufacturer's brake components are certified and approved for use in the EU, Russian Federation, and countries of the Customs Union. The company provides a one-year warranty for all products.

Advantages:

- Manufacturer's warranty;

- Protection against counterfeiting (a QR code is assigned);

- Planned expansion of the range of brake pads;

- Safety, durability, comfort.

Types of pads - composition, resource, pros, cons, prices

Discs and pads are subject to serious requirements: they must withstand high temperatures, temperature changes, and also have good thermal conductivity. For effective braking, the material must wear off evenly and not crumble. Brake pad manufacturers are constantly experimenting with materials and releasing new types.

Semi-metallic

The basis is an inorganic material, to which 30 to 60% metal shavings are added. It can be iron, copper, graphite. This mechanism is durable, it lasts 20 thousand km. Another plus is good heat dissipation, which means it does not overheat. Minuses:

- Noisiness;

- Inability to work at low temperatures.

Metal

This species contains a high percentage of metal. It is made from metal powders that are subjected to heat. It’s easy to determine the quality - run your finger over the surface, it should be smooth.

On budget models, roughness is noticeable, which indicates low quality.

Organic

Made from recycled fibers that provide softness to the material. Glass, resin, carbon, rubber, and Kevlar are suitable for its manufacture. The mechanism is less noisy than analogues, but wears out faster. Another disadvantage is that a large amount of dust is formed during braking.

Ceramic

This is the most modern look. The composition includes non-ferrous metals, ceramic fibers, and a small amount of metal. Thanks to this mixture, the mechanism gained low weight. But it costs more than its analogues. When using this type, brake discs wear out less and produce less noise than other types.

Visual inspection

When purchasing, you should pay attention to the presence of defects (chips, cracks in the pad material, bent metal parts). Pay attention to the presence of a mark of conformity of the model to the ECER90 standard on the packaging.