Let's look at ways to adapt the throttle valve without special tools in garage conditions, tested on many car models - everyone is happy.

Good afternoon dear friends. We continue to deal with the throttle valve. Last time we learned how to independently check the throttle position sensor, today we will see how to independently adapt the throttle position sensor. Let's consider two methods, the first may not work on some cars, the second gives almost 100% results. Most car owners were able to solve throttle problems using these methods.

How to understand that the throttle needs “retraining”

The need for adaptation arises in the following cases:

- Unstable idle;

- High engine speeds at idle or very low on the verge of “about to stall”;

- When replacing the throttle or cleaning it;

- If an error is detected in the control unit;

- When replacing the ECU.

There were cases when, after a long period of inactivity or the onset of cold weather, the engine did not want to start or idle normally. That is, literally the first night of frost, and in the morning the car does not want to work normally. If you do not have special diagnostic equipment and software, you can carry out the adaptation yourself.

At a service station, this service will cost from 700 to 1000 rubles, depending on the make of the car.

Why should you pay money right away if you can try to “train” the throttle yourself?

Method number 1 – dancing with a tambourine, battery and ignition

Warm up the engine to operating temperature. Usually 80-90 degrees is enough and we turn off the engine.

Disconnect the battery and remove the terminal from it. This is necessary to reset the parameters in the control unit. In a simple way - reset the ECU to factory settings. This will allow the unit to retransmit the damper values in the closed position.

We wait five minutes. This is enough for the control unit to be completely de-energized. We connect the terminal to the battery. Don't forget to tighten it to make better contact.

Turn on the ignition and wait 30-40 seconds without touching or pressing anything. At this time, you may hear a buzzing noise under the hood. This adapts the throttle, the motor moves the damper, determining its position and recording this data in the ECU. This is typical only for electrical and electromechanical remote sensing devices.

Turn off the ignition and wait 15 seconds. After this time, we turn on the ignition, wait until all the indicators on the dashboard go out and start the car. We check the engine at idle speed, the speed should be normal.

It may not work on cars: Audi with a 1.8 liter ADR engine, Opel Corsa, Octavia Tour 1.6 akl engine, 4th generation Golf, Audi A4 ADL B5 body. All cars have non-volatile memory, which cannot be reset by removing the terminal from the battery.

If you were unable to teach using this method, write your car model in the comments.

The need to adapt remote sensing

This definition refers to the operation (or training) that is carried out so that the ECU “knows” what position the throttle valve is in relative to the degree of depression of the accelerator pedal. This procedure is simply necessary if the engine is unstable at idle.

For most Toyota, Lexus, Mercedes, Nissan, and Audi cars, it is necessary to adapt the throttle valve, as this allows you to eliminate the malfunction. The procedure is performed in the following cases:

- in the event of a critical drop in the voltage of the on-board network (the battery is switched off or completely discharged);

- the ECU was replaced;

- the valve was cleaned and the throttle was removed;

- when replacing the throttle module itself;

- the accelerator pedal was replaced, usually with an electronic one.

It is worth noting that due to the layer of dirt, the gap between the damper and the body changes, and after cleaning the damper, its position has changed. But the ECU “has no idea” about this and continues to control the fuel supply according to previous indications (before the cleaning operation). Adaptation will completely eliminate this gap and restore engine performance.

Method No. 2 – Dancing without a tambourine, but with a pedal and ignition

Throttle valve calibration can be divided into three stages:

- Training with the gas pedal released;

- With throttle fully closed;

- Air supply at idle.

First of all, warm up the car engine to operating temperature. We turn off the engine and wait 10 seconds.

Stage one

We make sure that the accelerator pedal is released and nothing is pressing on it. Turn on the ignition for 2 seconds and turn it off.

The throttle valve is a key element of the engine power system. It regulates the amount of air supplied to the cylinders, which, in turn, affects the idle speed and the number of revolutions. From time to time, the operating mode of this part changes, so it is necessary to adapt it. Moreover, you must first clean the damper, otherwise all efforts may be useless. Unfortunately, not every motorist knows how these procedures are carried out, although in fact they are not anything complicated.

Adaptation using the example of some cars

Another method, which we will consider using the example of one well-known German brand, also involves adaptation without a computer. Here you should warm up the engine to a temperature of approximately 70-99°C. The battery voltage must be at least 12.9 Volts when the engine is not running. The action plan for how to adapt the throttle valve on a Volkswagen will be something like this:

- After warming up and turning off the engine, you should wait a short period (5-10 seconds).

- With the gas pedal released, turn on the ignition and wait 3 seconds.

- After 3 seconds, you need to press the accelerator pedal all the way 5 times and release it back. Act quickly, as you only have 5 seconds to do this.

- After the 5th exercise, you should wait a pause.

- After 7 seconds, press the pedal all the way again and hold it in this position until the “CHEK” indicator starts flashing (≈ 10 sec.), then it should remain on continuously (≈ 20 sec.).

- When the indicator lights up constantly, count to three and only then release the pedal.

- Start the engine (repeat if necessary), wait 20 seconds, then lightly accelerate (2000-3500). If the tachometer shows 700 rpm at XX (+- 50), it means that the adaptation was successful.

In this case, it is necessary to strictly adhere to the time intervals of each setting step. This is the only way the ECU training will go smoothly. But before that, it’s worth studying the adaptation features and the possibility of a manual procedure for your car. Perhaps only service station specialists can help.

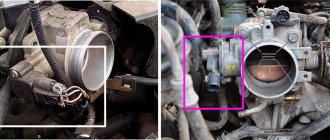

Removing the throttle

The throttle mechanism must be removed before cleaning and training. This is quite easy to do on a Toyota Corolla E120 and E150. Since 2002, the manufacturer began installing 1.6-liter power units on all cars in the series, so the dismantling process is the same for them.

The order for the Corolla Fielder is somewhat different, since the station wagon appeared in 2000 as a kind of offshoot from the main series. Nevertheless, the difference is insignificant, and it lies only in the principle of operation of the throttle, which is mechanical, so there is no need to look for an electronic sensor.

On later models, starting with the 2008 Corolla, the systems were unified and all powerplants now feature electronic throttle.

Under the hood, the engine is located openly, so finding the necessary elements is not difficult. Those drivers who are getting acquainted with the engine for the first time and do not know what this or that component looks like can see many photos on the Internet that show in detail all the external features of this or that part. The first step is to remove the air filter pipe, which is located on the left side of the power unit and on the right of the gas distribution mechanism. To disconnect the throttle itself, just unscrew the four bolts that secure the part to the timing belt. Now you can start cleaning the throttle body of the Toyota Corolla 150, which will be the same for the 120 models.

Cleaning the throttle valve

First of all, to clean the part you need to buy washing liquid for the carburetor. It costs about 200–300 rubles per can, so you don’t need to worry about the cost of the issue. In addition, you will need a dry cloth that should not leave any lint. So how do you clean your throttle body? Everything is very simple.

You need to spray the purchased liquid onto the part and gently wipe it with a rag. It is worth repeating the procedure several times until the dirt and deposits are completely removed.

Many motorists ask the question: “We clean the intake manifold, but engine performance does not improve. What are we doing wrong? The fact is that this part does not need to be touched at all. Of course, extra flushing will not cause harm, but there is no need to waste time on it. The deposits formed in the collector are insignificant, so they do not interfere in any way.

How often should you clean your throttle body? It is impossible to answer this question with an exact number, since it is recommended to carry out this procedure every time the engine oil is changed. Some people do this twice a year, and others once every two years. After how long the lubricant is changed, the same time it needs to be changed.

Cleaning the remote control

If the cause of unstable engine operation is a dirty damper, you should move on to cleaning it. To do this, you can contact a reliable service station. Among the large number of workshops, you can find one that specializes in specific brands (Audi, Volkswagen, Toyota, Mercedes and others). However, the owner can do all the work himself, since much experience and skills are not required in this matter.

At service stations, the cost of the procedure may depend on a number of factors:

- complexity of the work - for some cars, access to the remote control will require the dismantling of many parts;

- service station service level - as a rule, the larger the organization, the more expensive it is;

- location – in large cities you can leave more money than in the periphery.

Cleaning the throttle valve is a simple procedure, after which you usually need to think about how to adapt the throttle valve on a Nissan or any other car.

Any car owner can perform this procedure independently. No special knowledge or skills are required here. All you need to get to the damper are tools and rags (preferably soft ones). You also cannot do without a special product - mainly the carburetor cleaner “Carb Cleaner” is used.

Throttle valve adaptation

After the driver has successfully cleaned the part, you need to reassemble the entire mechanism in the reverse order, and then proceed to the main procedure.

Training should only take place if a number of preconditions are met. First, the power unit needs to be warmed up to operating temperature. Then you should turn off all electronics (headlights, DRLs, audio system, etc.). The car must be on a flat surface, since adaptation will require moving the gear lever to neutral.

After the car has been prepared, training should begin. First, you need to disconnect the battery terminal for 5 minutes. After waiting 5 minutes, you need to return it to its place. Next, the ignition is turned, but the engine itself does not need to be started. After all the indicators on the dashboard light up, you need to wait 30 seconds.

Leaving the ignition in place, you should again disconnect the terminal from the battery for the same time, then return it to its place, start the engine and wait 15 minutes.

As a result, the idle speed will be adjusted and the air supply will be normalized.

Fuel system or dirty intake?

When mentioning a dirty intake, many drivers immediately begin to suspect the fuel injectors for all the troubles. It must be said that such a fear exists, but, alas, it is not always confirmed. Let's first look at the symptoms associated with a faulty fuel system and a dirty intake. So, if the fuel system in a car is faulty, the following problems may occur:

- difficult starting;

- “triple” of the engine, both at idle and while driving;

- significant reduction in traction;

- slow speed increase;

- the car may stall frequently;

- The “Check Engine” icon appears on the dashboard.

Not a small set of problems, is it? With a faulty fuel system, all of these problems can occur individually or all together. However, such malfunctions are typical not only in the case of a faulty fuel system, but in 70% of cases, if several of the symptoms listed above are present, the problem lies in a faulty fuel pump or fuel injectors. This problem is difficult to solve on your own, because this will require the help of a qualified specialist and diagnostics of the electronic control unit (ECU) using a special scanner.

The problem with a dirty inlet is much easier to solve; for this you do not need to disassemble the fuel rail, etc., it will be enough to unscrew a few screws, disconnect the electrical wiring and remove several pipes. It is also worth noting that the problem of “dirty intake” is not displayed on the dashboard by the “Check Engine” indicator, but this only happens if the sensors (TPS and MAF) are working properly.

Let's look at the symptoms associated with a dirty intake:

- high idle speeds at the time of start-up, which do not fall below a certain level (usually the speeds do not fall below 1200-1500, less often - 900-1100);

- increased fuel consumption (can reach from 0.5 to 1.0 liters, depending on the condition of the engine);

- poor response to the gas pedal “the car stalls, does not drive at full power.”

Remember that if similar symptoms appear on your car, but the “Check Engine” warning light does not light up on the dashboard, and scanners do not detect errors during diagnostics, in 95% of cases the problem lies in a dirty throttle valve.

Elements of the diesel engine control system

Electronic engine control unit

Removal and installation

1. Disconnect the negative terminal from the battery.

Attention:

Wait at least 90 seconds after disconnecting the negative (-) battery terminal to prevent the airbag or pretensioners from deploying.

2. Remove the decorative engine cover by unhooking the 4 clips.

3. Remove the air filter housing cover:

- Disconnect the mass air flow sensor connector.

- Disconnect the electrical wiring clamp.

- Unhook the 3 clips and remove the air filter housing cover.

4. Unhook the electrical wiring clamp, unscrew the three mounting bolts and remove the air filter housing.

5. Remove the electronic engine control unit:

Remove the 3 bolts securing the engine ECU bracket.

Unhook the two levers by pressing the latches and disconnect the two engine ECU connectors.

*Press Lock*

Note

:

After disconnecting the connectors, make sure that they are not exposed to dirt, dust, or foreign particles.

- Remove the electronic engine control unit with bracket.

- Remove the 4 screws and two brackets from the engine ECU.

6. Installation is carried out in the reverse order of removal.

Diesel engine throttle

Checking the throttle position sensor

1. Connect the diagnostic tool to the DLC3 connector.

2. Turn on the ignition.

3. Turn on the scan tool.

4. Select the following options: Powertrain / Engine and ECT / Data List / Throttle Position.

5. With the throttle valve fully open, check that the values displayed by the meter are within specifications.

Note

:

Displayed value: at least 60%.

Attention:

During the test, the gearbox must be in neutral.

Checking the throttle valve

1. Turn off the ignition.

2. Wait at least 5 seconds after turning off the ignition.

Note

:

Be sure to turn off the ignition before performing this test. The fully closed throttle position is reached after the ignition is turned off.

3. Connect the diagnostic tool to the DLC3 connector.

4. Turn on the ignition.

5. Turn on the scan tool.

6. Enter the following menu: Powertrain / Engine and ECT / Data List / Diesel Throttle Angle.

7. Check whether the displayed value is within the specification (-5~5%). If the results are abnormal, replace the throttle body assembly.

8. Enter the following menu: Powertrain / Engine and ECT / Data List / Throttle Valve Fully Closed.

9. Check whether the value displayed by the instrument is correct when the throttle valve is fully closed (14.25~21.25°). If the results are abnormal, replace the throttle body assembly.

Removing and installing the throttle valve

1. Disconnect the negative terminal from the battery.

Attention:

Wait at least 90 seconds after disconnecting the negative (-) battery terminal to prevent the airbag or pretensioners from deploying.

2. Remove the decorative engine cover by unhooking the 4 clips.

3. Remove the 4 bolts, 12 clips, and remove the engine bottom cover.

4. Loosen the two clamps and remove air duct No. 3 from the throttle body and air duct No. 2.

5. Remove the throttle body assembly:

- Disconnect the throttle position sensor connector.

- Disconnect the throttle actuator connector.

- Unscrew the two nuts and two mounting bolts and remove the throttle body with the gasket.

6. Installation is carried out in the reverse order of removal.

Intake malfunctions, what to do and what to do?

Typically, malfunctions associated with the throttle valve on the Toyota Corolla 150 occur at high mileage (over 100,000 - 120,000 km). However, there are cases when malfunctions of the throttle assembly occur at short distances (around 60,000 km), in which case the causes of these malfunctions may be:

- a defective part in the throttle assembly (TPS - throttle position sensor) - practically never occurs;

- the so-called “throwing” of the throttle assembly (from the cylinder head side) with exhaust gas products due to the crankcase ventilation system is a common problem;

- the use of a low-quality air filter or its contamination (due to non-compliance with maintenance) is rare.

If problems arise related to a malfunction of the throttle assembly, do not panic ahead of time, because these problems can be easily solved with your own hands; you just need a little time and tools. However, before starting to disassemble the throttle assembly, we first of all strongly recommend diagnosing the electronic control systems (either at a service center or independently using a scanner).

And we warn all those who dare to repair the throttle assembly with their own hands that our editors are not responsible for your actions! You perform all work at your own peril and risk!

The ways to solve problems are as follows:

- with all sensors in working order (TPS and MAF), the throttle assembly is removed from the car, then washed, after which it is installed back and adaptation/learning of the throttle valve is performed;

- if the TPS sensor is faulty, the throttle assembly should be replaced with a new one (since the TPS sensor is installed directly in the throttle body body);

- If the MAF sensor is faulty, it should be washed or replaced with a new one.

The functionality of the sensors can be checked using a scanner; if there are no errors, it can be additionally checked using a multimeter/oscilloscope. More detailed information about sensor indicators can be found in the vehicle manual.

- throttle assembly assembly (with TPS): used - from 3000 rubles, new - from 6500 rubles;

- Mass air flow sensor (MAF): used - from 1500 rubles, new - from 4500 rubles.

Operating principle of damper position sensors

Knowing the types of throttle sensors, let's consider their design features and operating principles. First, let's consider a contact sensor or film-resistive sensor.

This element received its name film due to the use of a structural part in the form of a film. There is a track on the film along which a moving element—the slider—moves. The components of a contact potentiometer are:

- Housing made of plastic

- Film resistance. A positive charge is applied to the steel plate on one side, and a negative charge on the other.

- The moving element is a slider that is connected to the throttle valve

The principle of operation of the part is that a constant voltage is supplied to the track when the ignition is on and the engine is running. When the throttle is closed with the engine idling, the voltage at the output of the third contact does not exceed 0.7V. As soon as the driver presses the gas, the throttle position changes. As the damper moves, the slider moves along the resistive track. When the damper opens, the resistance decreases, which means the voltage at the third signal contact of the sensor increases. With the throttle valve fully open, the voltage on the signal wire is 4V.

https://youtube.com/watch?v=yzsa66o5pM4%3F

The voltage measured is sent to the ECU via a signal wire. The controller adjusts the fuel supply depending on the throttle opening value. Over time, the slider and film resistive element wear out, so the sensor fails and needs to be replaced. This part cannot be repaired, and if it breaks, replacement is required.

This is interesting! Most often, the sensor fails due to abrasion of the track. In this case, the voltage may not change at all when the engine is running or may change with sudden changes, which depends on the nature of the malfunction. The contact throttle position sensor has a different design, and therefore a different operating principle.

The functioning of non-contact type TPS is based on the Hall effect. By using this, the element in question lost its contacts, which is where it got its corresponding name. Instead of a contact plate, the design uses a permanent magnet. An integrated circuit operating on the Hall effect principle is built into the sensor body. The job of this chip is to sense changes in the magnetic field, which is achieved by changing the position of a permanent magnet.

A permanent magnet is attached to the throttle valve. When the damper opens, the magnet moves simultaneously. Changes in the position of the magnet are recorded using a microcontroller. The recorded values are converted by the microcontroller into an electrical signal. The magnitude of the supply voltage is similar to the contact sensor. That is why the contact sensor can be completely freely and without modifications replaced with a non-contact one.

This is interesting! Among the advantages of the contactless element is a long service life due to the absence of rubbing parts. Among the disadvantages, it should be noted the cost, which is 2 times higher than a conventional contact TPS.