The 1MZ-FE engine is the first representative in the MZ series - V6 gasoline engines (V-shaped, six-cylinder) produced by Toyota. The engine, like the two subsequent models 2MZ-FE and 3MZ-FE, has a cylinder block and two cylinder heads cast from aluminum alloy, as well as an intake manifold, for lightweight purposes. In each of the heads, according to the design, two cast camshafts (DOHC) are installed, 12 valves (24 valves in total) at the rate of 4 for each cylinder, including 2 for the intake and exhaust. The cylinder camber angle in the block is 60 degrees. The fuel supply system is injection. The piston rings and crankshaft (forged) are made of steel. 1MZ-FE engines were produced with a standard gas distribution system, as well as with a VVT-i variable valve timing system.

The first engines run on gasoline with an octane rating of 92 and develop a power of 210 hp. at 5400 rpm. The design of the pistons with recesses opposite the valve plates reduces the likelihood of valve bending when the timing belt breaks on these engines to a minimum. Later versions of power units were produced “tailored” for gasoline with an octane rating of 95 and higher, with the VVT-i system installed, which increased power to 220 hp. at 5800 rpm. In addition, turbocharged versions of 1MZ-FE engines were produced for the following Toyota cars: Camry from 1997 to 2000, Sienna from 1998 to 2000 and Solara from 1999 to 2000. The power of these engines increased to 242 hp.

The difference between the MZ and VZ series motors is in weight; accordingly, in the former it is reduced due to the aluminum block and lightweight pistons cast from aluminum, which have a molybdenum coating to protect against wear. According to foreign sources, reducing the weight of the MZ series motors did not affect their reliability, including their service life.

I think you will agree with me that the increased weight is not so critical in comparison with the repeated possibility of repairing cylinders in a cast iron block. Aluminum cylinders of MZ series engines are disposable, since the liners pressed into them cannot be replaced or bored, and they do not last forever. After the engine has reached the end of its service life, it can be repaired using the aggregate method, that is, replacing the cylinder block, crankshaft, etc., but this method is very expensive and most likely not cheaper than a contract engine.

Power steering belt.

Despite its small dimensions, the power steering belt performs an important function without which the operation of the power steering system is impossible. It is the power steering belt that drives the main element of the system - the pump. The drive requires proper attention and timely replacement. Most modern vehicle manufacturers recommend changing the power steering belt every fifty thousand kilometers.

Good luck on the roads!

Hi all! =)

So... I solved some problems with small losses. The jamb was really in the power steering belt!

Symptoms:

1. The steering wheel sticks, it turns hard, especially after parking, it starts to rotate only with the throttle applied.2. The power steering pulley stops when the belt whistles, as if the power steering pulley is jamming.3. When the steering wheel sticks, there is a whistle under the hood.4. Video of the whistling sound, here.

The problems were due to:

1. Poor tension of the power steering belt. I checked it visually with my finger, it was not tight enough.2. The old belt was cut by the power steering pulley, either the quality of the belt is poor, or it was actually my fault... when I changed the crankshaft pulley, it was a little rusty, when I bought it, they told me to sand it a little, otherwise it would cut the belt, I didn’t listen. In general, one of two things. The last time I installed the belt was a year ago, but a year later the problems started. True, a little less, they started in the winter. In general, before replacing the belt last time, the steering wheel was also dull, but not so hard. Another problem was that the belt stretched, I don’t remember anymore.

I bought a new belt, again from Masuma

I hope it will last a long time. I already bought an air filter, pads from this company... ugh, ugh, ugh, everything is fine.

But the old belt, you can see visually how it was cut...apparently it was slipping:

Now the steering wheel turns absolutely beautifully, no whistles or wedges, no wedging or stopping of the power steering. But reading the Internet, they even say that if the power steering sticks, then they say that’s it, either the bearing or the power steering pressure reducing valve is closed.

And often in services they say, that’s it, buy a new one, then the person buys, exchanges and in the end drives happily ever after. But when the power steering is changed, the belt is naturally tensioned again, and all the symptoms disappear. And the owner and servicemen think that yes, the power steering was really to blame. Well, they either think or they are deceiving)) Who knows =)

So don’t rush to change the power steering, check the belt tension, or better yet, replace it. And I was also upset, I thought that the guru was fucked up, then I decided to write here and ask you for advice, uv. readers.

I found an article from the Internet, someone wrote it, I don’t remember the link anymore. I've scoured the internet looking for solutions to these problems:

In the extreme position of the steering wheel (and continue to press), the valve supplying oil to the corresponding part of the rack remains open. All the pressure created by the pump is directed there and is not released. Therefore, the load on the oil pump is maximum and if the belt is bad and there is not enough tension, the pump stops. Otherwise, the pump has a pressure relief valve, and it must relieve pressure. In the normal state of the valve racks, oil passes directly into the return line and the pressure is minimal. There the system is very simply designed: a torsion bar on the shaft and the valve moves up and down under load, opening the desired channel. Nothing can buzz in the rack. All the noise is from the pump. The blades may wear out.

Part 1 Replacing the power steering belt

Necessary materials:

- wrench or ratchet wrench;

- (you may need) a flashlight;

- hydraulic lift or inspection hole;

- a long flathead screwdriver and also a flathead screwdriver;

- penetrating agents (WD-40);

- new power steering belt to replace;

- a new power steering belt pulley to replace it (in some cases);

- protective equipment: safety glasses and gloves.

Step 1: You need to lift the car on a lift or place it over a hole in order to have access to the engine compartment from below.

Step 2: Disconnect the battery from the vehicle's power supply. Once the vehicle has been raised and supported on a lift or otherwise has access to it from below, the first thing that must be done before replacing the power steering belt is to turn off the power supply.

Locate the vehicle's battery and disconnect the positive and negative battery cables before proceeding.

Step 3: Remove the engine protection, if equipped. Depending on the make or model of your car, you will need to either use a wrench or a screwdriver.

Step 4: If necessary, disconnect the alternator belt first. On some vehicles, the alternator belt will prevent the power steering belt from being removed. This is common on four-cylinder engines.

If so, consult your vehicle's manual and follow the instructions for removing the alternator belt. In most cases, you will only need to remove the belt, not the alternator itself, to gain access to the power steering belt.

Step 5: Locate the power steering pump. On most vehicles, the power steering pump will be located on the driver's side of the engine compartment. You may have to again refer to the schematic designation of the units of your car model in the operating instructions for the car.

Examination

1. Check for wear, cracks or other signs of damage. If any defects are found, replace the poly V-belt.

- The belt has cracks.

- The belt is worn to the point where the fibers are exposed.

- Belt rib elements are missing.

3. Check that there are no foreign particles in the tensioner by turning it clockwise and counterclockwise. If there is a malfunction, replace the poly V-belt tensioner.

Toyota Carina White Bride Logbook Replacing power steering fluid

So I decided to replace the fluid in the power steering, which, as it turned out, was not in vain. We roll the front wheels so that they rotate without load. We clean the power steering pump reservoir from dust and dirt

Open the reservoir cap and see what color the liquid is.

Using a syringe with a piece of hose, we pump out the liquid that is in the reservoir itself from the washer and again wonder what color it is

Remove the return hose from the tank, which goes from the rack to the tank

And we direct it into a pre-prepared bottle 0.5

Turning the wheels left and right, we understand that the liquid is no longer flowing. We fill the tank with new, clean liquid

We hear that something is flowing somewhere, it turns out that we forgot to put a plug in the place of the removed hose

Pour the liquid into the tank again, start the car for 3-5 seconds, turn it off, we see that the tank is filled from the return line, and the tank is empty

We see that the liquid is becoming lighter. Fill and drain, and so on 3 times (that was enough for me), almost clean liquid flowed from the return.

We fill in the remainder and see (and the photo shows) that the liquid in the tank is clean red

We start the car and slowly turn the steering wheel left and right 5-6 times, turn it off, see how there are air bubbles in the tank, add fluid if necessary.

We smoke for 5 minutes and start it again, 5-6 turns of the steering wheel and smoke again, and so on until we see that the air bubbles are gone. As we pour the last portion of liquid, we understand that the result is obvious! This is where all the work ends. Time taken 1-1.5 hours, budget - about 300 rubles,

Tuning

One of the easiest ways to increase power levels is to use supercharged tuning. Since this engine model was aimed at the foreign market, KIT kits were produced by Toyota's TRD subsidiary, as well as a number of other manufacturers.

Piston 1MZ: 1 - polymer coating

Toyota 1MZ V6 3.0 internal combustion engine tuning algorithm:

- Installation of an intercooler and installation of a compressor providing a pressure of 0.5 bar;

- Installation of nozzles with a power of 320 - 360cc;

- Modification of the exhaust pipe diameter by 2.5 inches;

- Installation of the appropriate firmware version (adapter required);

Such measures will increase power to 270 horsepower. However, there is also a flip side to the coin, since such modifications not only cost a pretty penny, but also significantly reduce the life of the unit.

Crankshaft 1MZ

The possibilities associated with mechanical tuning are quite limited. This is due to the impossibility of boring the cylinder head channels, as well as the high cost of replacing all camshafts or valves.

Replacing alternator belts, power steering and tension roller bearings on a Nissan Cefiro A33.

A person without experience can change the belts and tension roller bearing, but it is difficult to do because The work space is very limited and without a pit it is even more difficult to do this, and without having enough tools it is better not to try to do this. In order to change belts on cefiro you need to have suitable belts from the list below.

Power steering belt number:

- 4kp775

- 4kp773

- 4kp780

- 4PK0773

Belt number for generator and compressor:

- 6kp1100

- 6kp1095

- 6kp1090

Belt number for the alternator bypassing the air conditioning compressor:

- 6PK860

- 6PK880

- 6PK870

Tension roller bearing number:

- bearing No. 301

- 6301

- 6301RDH

- 63012RS

Tension roller bearing dimensions 12*37*12

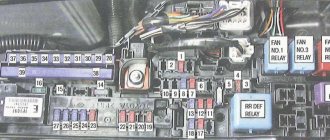

Replacing the power steering belt.

Having driven the car into a pit, if you remove the wheel it will be more convenient to get to the steering wheel adjusting screw. If you are going to change two belts, then the first thing you need to do is change the power steering belt because it is located behind the alternator belt and it will not be possible to remove the power steering belt without the alternator belt.

The direction in which you need to turn the nuts and bolts when replacing belts is indicated.

The first thing you need to do is loosen the locking bolt of the power steering belt tensioning mechanism using a 12 mm spanner or an extension, it’s hard to get to it, but getting to the adjusting bolt is even more difficult; I did this from the hub side.

After loosening the locking bolt, you need to loosen the adjusting bolt by screwing it in until the belt loosens and pull it off. The diagram also shows a bolt on the back of the power steering, but I didn’t touch it, although I probably should have.

bolt on the back of the power steering

Replacement of alternator belt and air conditioning compressor.

First of all, we loosen the tension roller nut; it is not so difficult to get to it, and only then use the adjusting nut to loosen it so that the belt is loosened and you can pull it off.

Changing the alternator belt is easier than the power steering belt, if only because there is more free space, after the belts are removed, put on the power steering belt and then the alternator belt and do everything in reverse order.

Replacing the tension roller bearing.

The bearings listed above are all suitable for cefiro and you can select others using their numbers; they are sold at an attractive price.

After removing the generator belt, you need to unscrew the 3 bolts that hold the roller and remove it.

When replacing a bearing, it is best to press it out with a vice rather than gouge it out with a hammer. It is advisable to additionally lubricate the new bearing, even though it is lubricated from the factory, before installing it in the tension roller.

Pressing the bearing into a roller

New and old bearing