Using the crankshaft position sensor (CPS) in the internal combustion engine, its rotation angle and rotation speed are determined online. If error 12 is displayed, the engine control unit (ECU) will not receive or receive distorted signals and the ECU will not be able to generate the necessary commands. DPKVs are divided by type into Hall sensors, inductive and optical. High-end GM V engines have sensors that measure harmonic vibrations of the shaft, which increases the accuracy of the measurement to degrees.

Toyota Corolla ICE error codes

Quite often, sensors report engine malfunctions, which can occur either as a result of natural wear and tear on internal parts or due to improper operation of the machine. Most often, owners of this model encounter the following error codes during diagnostics:

- P0011 – incorrect camshaft position, i.e., desynchronization of the shafts, which causes the valve timing in the CVVT system to change and the element gear to light up.

Such a problem can occur due to incorrect position of the contacts in the gas distribution system valve, contamination of the piston channel by the oil flow, or breakdown of the phase regulator. The CVVT system itself can also be damaged, but this is less common.

If the P0011 fault message starts to light up, you must first check the serviceability of the sensor, inspect it for absence of oxidation and correct connection.

Then you need to look at the condition of the phase sensor: it may be contaminated with a layer of carbon deposits due to the use of low-quality oil. Then you should check the VVT valve for operability and, if it breaks, install a new part, and also see if there is any mechanical damage to the camshaft gear, which could not fit correctly.

- 2196. Toyota Corolla, in which computer diagnostics has detected such an error code, may receive an excessively rich mixture (1 sensor in 1 row should be checked). When code 2196 appears, you should check the condition of the EFI relay, air intake system, injectors, check the pressure level in the fuel system, and also see if there is an open circuit or short circuit in the electrical circuit of the sensor itself.

- P2118. This error means that the engine throttle actuator is not functioning properly because the current values are outside the normal range. If the check engine light comes on and the diagnostic code shows this code, you should check the ETCS power supply circuit for an open, any fuses that may be blown, and the ECM system. The problem may also occur due to the car battery being discharged.

- P2103. The code indicates that there is too much current in the throttle actuator circuit, which is necessary to move the throttle valve. The test reveals that its value exceeds 10 A for 0.1 s or 7 A for 0.6 s.

To fix the problem with the P2103 signal, it may be necessary to check the circuit for a short circuit; in some cases, it is necessary to change the damper itself or the housing assembly.

- P0606. If such an error starts to appear, this indicates a malfunction in the engine control unit. The cause of the problem is the ingress of moisture, which causes corrosion of the duralumin body, or clogging of the drainage hose leading from the car stove. You can remove traces of corrosion using alcohol or alcohol-containing products manually; after drying, the light should go out.

Engines 7A-FE 5A-FE 4A-FE

The most reliable Japanese engines.

The most common and most widely repaired of Japanese engines is the (4,5,7)A-FE series engines. Even a novice mechanic and diagnostician knows about possible problems with engines of this series. I will try to highlight (gather into a single whole) the problems of these engines. There are not many of them, but they cause a lot of trouble for their owners.

Toyota Corolla gearbox errors

Toyota Corollas of 2006, 2007 and later years of production are characterized by problems with the gearbox, especially often they happen with modifications equipped with a CVT robot. At the same time, the gearbox malfunction check lights up on the dashboard, and computer diagnostics can identify the following problems:

- Error P0909, indicating a malfunction of the rocker mechanism. In a manual transmission, gear selection is performed by means of an electric drive (actuator), which consists of a pair of electric motors, travel sensors and a gear that drives the engagement shaft of the desired gear in motion. The appearance of error code P0909 means that the travel sensor, the actuator itself or the hinge/fork, which are responsible for the switching process, are faulty.

- P0810. The error indicates incorrect behavior of the electric motor: the instruments register a clutch current of more than 22 A for 2 s, the clutch position deviates from the norm by 0.3 mm or more, and the movement of the mechanism is too slow. With code P0810, a control error may occur as a result of a damaged actuator, a faulty TCM, or a faulty travel sensor.

If a problem occurs when installing a new drive in the assembly, the mechanism clamp must be adjusted before doing this, otherwise P0810 (control error) cannot be cleared.

- When replacing the sensor, it is necessary to configure the electronics for the transmission system. If the above actions do not help and the lamp does not go out, you should replace the TCM system so that error P0810 can no longer occur.

- P0920. This code indicates a malfunction in the electrical circuit of the shift drive, which ensures the operation of forward gears. In this case, the voltage supplied to the gearbox actuator is too low or absent; When checking, you should find out the condition of the electric motor, TCM, and check the electrics for a short circuit.

- P0751. This command reports that the solenoid valve is stuck when the transmission is in the off state. To fix the error, you must do the following:

- Check the oil level in the gearbox.

- Accelerate the vehicle to a speed of 72 km/h to check the throttle opening degree.

- Check that the gear ratio and valve e/m correspond to the required values.

How to solve a problem

Before replacing, you need to check the sensor number in the catalog. Only original devices are suitable for replacement. Its cost is high, but products from other companies will not work. And the Chinese fake will last no more than one month.

The procedure for replacing a non-functioning sensor with a new one occurs in the following order:

- Disconnect the terminals from the battery.

- Locate and remove the oxygen sensor.

- Cut off the mechanism chip, re-solder the wires.

- Be sure to put heat-resistant rubber cambrics on the soldered wires - its operation is associated with the high heating temperature of the sensor.

- Install in reverse order.

If the error continues to remain on the dashboard monitor, then reset it by removing the positive terminal from the battery.

Now the car enthusiast knows what to do if the numbers 12 and 21 are displayed on the scanner. With the help of simple instructions, he can correct the errors himself.

Other errors detected during diagnostics

When checking the condition of Toyota Corolla systems, other problems may be identified regarding the condition of the power steering, electrical systems, airbags, climate control and other structural elements. Most often, owners encounter the following cases:

- Error P0351 or P0353. These malfunctions are due to the fact that during engine operation the IGF signal is not received by the ECM system. The problem with code P0353 should be looked for in the ignition system. First, it is checked for short circuits, then coils 1–4 are inspected and, if the diagnostics do not reveal problems in these elements, and error P0351 or P0353 does not disappear, the ECM is replaced.

- Code P0136 indicates that the oxygen sensor is faulty: the signal does not exceed 0.55 V when the car is moving at a speed of more than 40 km/h, the engine is warming up to a temperature above 40 degrees Celsius and at a speed level of more than 1400. The problem is why code P0136 may appear , consists of a break in the electrical circuit or a malfunction of the sensor itself.

- Error P0500, indicating damage to the vehicle speed sensor. The instrument fault signal P0500 may come on in the cruise control state and the current signal is interrupted for 0.14 s longer. When P0500 appears, it is necessary to check the electrical system for a short circuit. If the problem is not a failure, and error P0500 has not disappeared, it is worth scanning the instrument panel, the speed sensor itself, the ECU of the anti-skid mechanism and the body. P0500 is an error that is reset after replacing the sensor or electrical components.

- P0133. The code indicates low performance of the oxygen sensor circuit in row 1. The cause of the problem may be a short circuit, a problem with the air intake system, incorrect pressure levels, or a faulty or clogged injector. In addition, the malfunction may be that the sensor itself has burned out.

- Code P2196 indicates a continuous supply of an excessively rich mixture. You should check the oxygen sensor, EFI relay, sensor heater and circuits, and if the problem is not caused by failure of these devices, the cause is the condition of the ECM.

In addition, when diagnosing a Toyota Corolla, you may encounter code P0115: it indicates a malfunction of the cooling fluid temperature sensor (error 22). Also, some owners are faced with the ECU data bus being disconnected: this problem is designated as error 94, and its cause is a malfunction in the CAN system. For the Corolla E120 model, it is not uncommon to receive an error about a malfunction of the protection system: you should check the airbags and make sure that the connectors under the seats are not disconnected.

The car's steering wheel, power steering, Airbag system, or battery may be faulty. A red signal on the dashboard indicates a problem with the corresponding system, and the car may turn on the check and stall: this is especially true if there are problems with electrical systems in cold weather. In this case, it is worth checking the battery charge and sequentially diagnosing various parts of the wiring: the error can most often pop up due to a short circuit.

Modern scanners

There are now many scanners available for reading car error codes that completely decipher error codes. These programs are translated into Russian, are easy to use and allow you to configure vehicle parameters. For example, the time when the headlights go out after turning off the ignition, after how many seconds the lights in the cabin go out when boarding, disembarking, and more.

The car owner should think about purchasing diagnostic equipment. Not bad manufacturers of diagnostic devices: Launch, ELM, Autel, Autocom, Carman.

Scanner Launch

Actions to take when an error occurs

What to do if the check engine light or another system light comes on? If errors occur in the climate control, airbag, battery, actuator or internal combustion engine, a reset should be performed after diagnostics: for this you can use a scanner or perform electrical manipulations.

Resetting the error for a Corolla 150, Toyota Corolla E120 or another modification of any year of manufacture is carried out according to one algorithm: you can turn on the ignition, press the brake pedal several times, and then repeat the procedure with the ignition off.

When diagnosing an E150 or Corolla E120 model for errors with a scanner, a reset can be performed quickly with just a few button presses.

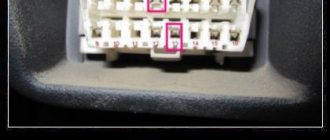

Diagnostic connectors Camry 40

The diagnostic connector in the Camry 30 is located to the left of the steering column.

The OBD 2 diagnostic connector for Camry 40, 50 and 55 is located under the steering column below the dashboard next to the pedal assembly (photo attached).

Camry diagnostic connector location

Conclusion

Computer diagnostics of a Toyota Corolla E150, 120 or other modification for most modern cars is performed through the OBD II connector, and during the test the device can show a code with the index P, which indicates the presence of problems. When such errors appear, it makes sense to check the engine of a Toyota Corolla released in 2008 or later, and conduct a detailed check of the condition of the gearbox, clutch, electrical system or other system, depending on the specific code. The error is reset after the problem is detected and corrected; cleaning is done by issuing a command from the scanner or resetting the terminal: in the first case, the result will appear instantly.

Injectors (nozzles).

Injectors are solenoid valves that inject fuel under pressure into the engine intake manifold. The engine computer controls the operation of the injectors.

Over many years of operation, the nozzles and needles of the injectors become covered with resins and gasoline dust. All this naturally disrupts the correct spray pattern and reduces the performance of the nozzle. With severe contamination, noticeable engine shaking is observed and fuel consumption increases. It is possible to determine clogging by conducting a gas analysis; based on the oxygen readings in the exhaust, one can judge whether the filling is correct. A reading of more than one percent will indicate the need to flush the injectors (if the timing belt is correctly installed and the fuel pressure is normal). Either by installing the injectors on a stand and checking the performance in tests, in comparison with a new injector. Nozzles are washed very effectively by Laurel, Vince, both in CIP installations and in ultrasound.

Engine fault codes and methods for erasing them

Fault codes for gasoline engines (Toyota)

12 – Crankshaft position sensor (P0335) 13 – Crankshaft position sensor (P0335, P1335) 14 – Ignition system, coil No. 1 (P1300) and No. 4 (P1315) 15 – Ignition system, coil No. 2 (P1305) and No. 3 (P1310) 16 – Automatic transmission control system 18 – VVT-i system – phases (P1346) 19 – Accelerator pedal position sensor (P1120) 19 – Accelerator pedal position sensor (P1121) 21 – Oxygen sensor (P0135) 22 – Coolant temperature sensor fluid (P0115) 24 – Intake air temperature sensor (P0110) 25 – Oxygen sensor – lean signal (P0171) 27 – Oxygen sensor No. 2 31 – Absolute pressure sensor (P0105, P0106) 34 – Turbocharging system 35 – Turbo pressure sensor 36 – CPS sensor (P1105) 39 – VVT-i system (P1656) 41 – Throttle position sensor (P0120, P0121) 42 – Vehicle speed sensor (P0500) 43 – Starter signal 47 – Auxiliary throttle position sensor 49 – Pressure sensor fuel (D-4) (P0190, P0191) 51 – Switch status 52 – Knock sensor (P0325) 53 – Knock signal 55 – Knock sensor No. 2 58 – SCV drive (D-4) (P1415, P1416, P1653) 59 – VVT-i signal (P1349) 71 – EGR system (P0401, P0403) 78 – Injection pump (D-4) 89 – ETCS drive (P1125, P1126, P1127, P1128, P1129, P1633) 92 – Cold start injector (D-4 ) (P1210) 97 – Injectors (D-4) (P1215)

Why is the check engine light on and what should I do?

| Cause | Method for eliminating it |

| Low fuel quality | Drain the gasoline from the tank and fill the car with fuel from another gas station or with a higher octane number. |

| Spark plugs are faulty | Check and replace part if necessary |

| No spark from cylinder | |

| The wiring or coil is acting up | |

| Lambda probe is faulty | Unit replacement only |

| Catalyst | |

| Injectors are dirty | Cleaning |

| The mesh in the gas tank or the fuel pump requires inspection | The gasoline supply pressure must be at least three atmospheres. If the indicators are different, repair or replace the components |

| Oil level | When the indicator lights up when the power unit heats up, turn off the engine and hear atypical engine sounds. We advise you to identify oil leaks, thereby you will find the location of the crack |