All errors TOYOTA 4RUNNER, ALLEX, ALLION, ALPHARD, ALTEZZA, ARISTO, AURION, AURIS, AVALON, AVENSIS, AYGO, BB, BELTA, BLADE, BREVIS, CALDINA, CAMI, CAMRY, CELICA, CELSIOR, CENTURY, COROLLA, ECHO, ESTIMA , FJ CRUISER, FORTUNER, FUNCARGO, GT86, HARRIER, HIACE, HIGHLANDER, HILUX, INNOVA, IPSUM, iQ, ISIS, IST, KLUGER HYBRID, KLUGER V, LAND CRUISER, LAND CRUISER PRADO, MARK, MARK X, MATRIX, MR 2 , NADIA, NOAH, OPA, PASSO, PLATZ, PREMIO, PREVIA, PRIUS, PROBOX, PROGRES, RACTIS, RAUM, RAV4, RUSH, SAI, SEQUOIA, SIENNA, SIENTA, SOLARA, TACOMA, TUNDRA, URBAN CRUISER, VANGUARD, VELLFIRE, VENZA, VERSO, VITZ, VOLTZ, VOXY, WILL CYPHA, WILL VS, WINDOM, WISH, YARIS.

Toyota Auris 2007, engine Gasoline 1.6 liter., 124 hp, Front drive, Robotic — vehicle breakdown

Comments 22

The issue here is the coil or its cracked tip. You can try covering it with 1-2 layers of heat shrink; if that doesn’t help, change the coil. I also installed Denso IXEH22TT spark plugs, but I bought them from the office. Denso dealer, because I bought fake SC20HR11 in auto stores twice and returned it (externally very high quality made).

I read your post. I bought an NGK coil, and before that I bought 4 Tesla repair kits and then it occurred to me - why change the coil right away if the error rarely pops up, maybe it’s in the tips... As a result, I repaired the tips a few days ago in all the snags, I put the NGK in stock.

What kind of repair kit is Tesla - can you give me the number? Did you repair the coil with this repair kit?

The same thing happened to me because of fake candles. Change quickly before the coils are finished.

Already ordered candles

Denso IXEH22TT, and before that I installed the “original” ones in Toyota boxes, wrote in the BZ, but I also think it’s a fake

My situation is the same) I also installed the original ones and replaced them with TT ones.

Denso IXEH22TT, and before that I installed the “original” ones in Toyota boxes, wrote in the BZ, but I also think it’s a fake

I’ll also order the Bosch iridium ones for comparison) but in general the factory German Bosch ones seemed to me to be of better quality than the factory Denso ones.

Candles or coils.

It could also be from the fuel; recently a friend from Minsk had a similar situation. After refueling. I removed the clamp. All is well now

The same thing happened, despite the fact that during diagnostics it later showed that the coil was normal, occasionally an error popped up... then it started to show up together with the ABS, and the last step was the appearance of a failure during acceleration... the coil was already running by this time, I changed the coil and all the errors disappeared ! And so for information, the coil of the 3rd cylinder was

This happened a month ago. P0354 is an error in cylinder 4 (what remains to be seen). Swap the coils of the 3rd and 4th cylinders. If it displays error P0353, then the coil is to blame. If P0354 remains, then you need to look at the spark plugs, or there is a more serious problem. I changed the coil, installed NGK for 2000 rubles.

A friend from Toyota said the same thing. Well, thanks anyway!

Tell me, does it matter with which cylinder to change the coils?

Doesn't matter. The coils are the same. But the problem I had was not with the coil, the tip repair kits helped, see further on the topics. And the new coil is still in the garage)) www.drive2.ru/l/471395820273402018/

This happened a month ago. P0354 is an error in cylinder 4 (what remains to be seen). Swap the coils of the 3rd and 4th cylinders. If it displays error P0353, then the coil is to blame. If P0354 remains, then you need to look at the spark plugs, or there is a more serious problem. I changed the coil, installed NGK for 2000 rubles.

Yesterday I did just that, but in the end the error remained the same. I ordered candles. Today I get into the car and there is no error at all.

Thank you. How did the Tesla repair kit perform? He looks like an Englishman, right?

Technical defects appear sooner or later in cars of all manufacturers, including Japanese ones. The driver can decipher Toyota error codes independently, and it is possible to determine system malfunctions without the use of scanners. If a car enthusiast has never encountered such a problem before, then this article will help you understand all the nuances and perform the work at a professional level.

Self-diagnosis of the “Check engine” error on a Toyota Corolla

Self-diagnosis is a simple and very fast way to eliminate errors and find their causes. To carry it out, we will need a smartphone - in our case, a Samsung phone running on Android. We will also need OVD2-VT - this is a special adapter that, through a wireless connection to the phone, allows you to decipher and eliminate error codes. All this pleasure will cost you 1000 rubles. This is how much the adapter costs, which plugs directly into the diagnostic connector located under the dashboard on the driver’s side.

So we have a broken down car, we bought an ELM and we have a phone. What's next? And then we need to configure our equipment. You should start by installing the software on your phone. We will use a program such as “Torque. By its name, you can easily find it on the Android Market, download it there and install it on your mobile device.

In fact, there are a huge number of similar programs in this application store, but we chose this one due to its convenience. This program can be completely customized for yourself. Setting up indicators that will be displayed during diagnostics, the ability to decipher stakes and reset errors - all this is available in this application. The program is simple and has a nice user interface. The most difficult part of this program is filling in the data about the vehicle being tested. By the way, it is worth noting that not only Corollas are suitable for testing, but also other cars, including makes and models.

Let's proceed directly to self-diagnosis. We have installed the program, after which we need to insert the adapter into a special diagnostic connector. In the photo shown below there is a special connector - it is highlighted in a red circle.

We place the phone on the stand, if one is available. Next we need to start the car and turn on Bluetooth on the phone.

After Bluetooth is turned on, launch the program on the phone. After a few minutes, the program will load and begin transferring data from the adapter to the phone. Which in turn will display engine parameters on the phone screen. The photo below shows the main working screen of the program.

In order for us to diagnose our engine and finally understand why the “Check Engine” light is on, we need to go from the main table to the appropriate section of the program, it is not difficult to recognize it, you can even do this by the engine icon. By clicking on it, the program begins to automatically read the ECU memory. When scanning, errors are detected, if any, of course, which are displayed by indicating the codes and their descriptions. After which, if you have access to the Internet, the program allows you to find out more information from the errors displayed and understand what actually is the cause of your malfunction. And finally, after you have figured out what the problem is, the program gives you the opportunity to erase all errors from memory. After clearing the computer’s memory, the error disappears and the “Check” light stops lighting up on the dashboard and annoying you. Below this process is shown in pictures for greater convenience.

So, the process of checking the engine of your car is completed, you know its reason and can confidently repair the unit that has become faulty. And the light bulb completely stops burning. In general, an excellent program for solving similar problems with the engine. However, it is disappointing that using such an adapter you can only diagnose the engine, that is, it will not be possible to diagnose the ABS or other components and systems of the car.

It is also worth knowing that resetting a lit light is not always possible, since it is possible that you actually have a serious engine malfunction. So the program can only show the malfunction, and it can reset the error only after repair, that is, after the cause of the error has actually been eliminated.

That's all. The question is quite nervous, but it also has its advantages. For example, the price of the issue, as well as the ability to independently find out the cause and eliminate it, if, of course, you understand your car. Good luck to everyone, and less problems with your pets.

Toyota car diagnostics

Diagnostics are available on cars of the entire Toyota model range and are divided into two types:

- mechanical;

- computer

Before starting electronic diagnostics, the driver must ensure that all systems and main mechanisms of the Toyota vehicle are in working order. To do this, you should check the fuses, electrical wiring, and also examine the connections and components of the vehicle for damage.

If any serious problem is detected, it must be eliminated, and only then carry out computer diagnostics, which can happen:

- preliminary;

- post-accident;

- planned;

- pre-sale

Step-by-step self-diagnosis

For self-diagnosis, the driver needs to work with the DLC 1 and DLC 2 connectors. This abbreviation stands for Data Link Connector, which in English means a connector for connecting data. DLC 1 looks like a plastic box with a lid on top. It is located under the hood, most often on the left. It is easy to find by the inscription Diagnostic.

Diagnostic signature on the connector

In older models, the diagnostic connector is shaped like a yellow circle and is located near the battery. There are no DLC2 parts in cars like the Corolla AE 100.

Fault codes for older car models: Toyota Corona 1992, Karina 1992-97, Toyota Mark are read only by flashing indicators.

In new models, DLC 2 is located directly in the cabin, under the dashboard and “at the feet” near the steering wheel. Most often it is round and is used during inspections carried out using special equipment.

Round DLC2 connector

When performing self-diagnosis by shorting individual contacts of the connector, only by connecting them in the required sequence can you obtain the correct code for decoding.

The following steps will help you find out if there are faults in the engine and/or gearbox system:

- Find the first DLC connector 1 labeled Diagnostic.

- Remove or unscrew the protective cover of the box. Below it there should be a diagram indicating the connector outputs.

- Take a wire, piece of wire, or other thin metal object (such as a paperclip) and install a jumper between the terminals labeled TE1 and E1.

- Turn on the ignition. Check that the furnace or air conditioner is not working.

- Look at the O/D (for transmission) and Check Engine (for engine) lamps. Memorize or write down the number and intervals at which the lights blink.

DLC 1 connector diagram

Everything is fine with the car and no damage to the internal combustion engine or transmission was detected if:

- the indicators flashed evenly with the same interval and duration of illumination more than 11 times;

- The Check Engine light illuminates for a long time and evenly at intervals of 4.5 seconds (this means that the code is supplied using type 10).

Any other combinations of light bulbs indicate a malfunction in the engine systems, gearbox or other mechanisms in the car.

If the circuit on the back of the cover has been erased, you cannot find the contact or you are not sure that you have closed the right one, you must:

- Turn on the ignition.

- Connect one of the wires of the control lamp to ground (to the car body).

- Connect the second wire one by one to each contact of the connector.

- Complete the test when the Check Engine light starts flashing on the dashboard.

It will be more convenient if someone helps you monitor the light bulb while you change the position of the wire.

Recognize fault codes using two flashing light systems.

The first setting option will allow you to find out errors indicated by a two-digit code (type 09):

- indicating the code, the light comes on for a split second;

- the time interval between pulses is also a fraction of a second;

- pause between tens and ones in one code is 1.5 s;

- the break between different codes is 2 and a half seconds;

- series of combinations of different faults are separated by 4.5 s.

This code should be “read” according to the following rules:

- duration of indicator glow within one pulse – 0.5 s;

- the pause between blinks within one code lasts half a second;

- break between different codes – 2.5 s;

- series of combinations of breakdowns are separated by a pause of 4.5 s.

The video shows diagnostics using type 9 code, author Dmitry Kuzmin:

Failures in the ABS system are determined using the same scheme, but the TC and E1 terminals are closed. The SRS and 4WS fault codes are read by the corresponding sensor with the same contacts closed as in the ABS.

Diagnostic connector DLC 1

Contacts TE1 and E1 on the connector

Closing contacts

Location of the connector under the hood

Troubleshooting

Type 9 error codes common to all Toyota vehicles are represented by two-digit codes.

| Code | Decoding |

| 11 | No power to EFI unit |

| 12 | No signal from the engine speed sensor |

| 13 | No signal from the engine speed sensor at speeds above 1000 rpm |

| 14 | There is no signal from the minus ignition coil or from the minus coil number one (if there are two of them) |

| 15 | There is no signal from the minus of ignition coil number two |

| 16 | There is no connection between the automatic transmission control unit and the engine control unit |

| 17 | Incorrect signal from camshaft position sensor number 1 |

| 18 | Incorrect signal from camshaft position sensor number 2 |

| 21 | Incorrect signal from the oxygen sensor, if the engine is V-shaped, then the heater of the left main oxygen sensor is faulty |

| 22 | Incorrect signal from engine temperature sensor (THW) |

| 23 | Incorrect signal from the intake air temperature (THA) sensor |

| 24 | Incorrect signal from the intake air temperature (THA) sensor |

| 25 | Mixture too lean |

| 26 | Mixture too rich |

| 27 | Incorrect signal from the additional oxygen sensor (left for V-engines) |

| 28 | Incorrect signal from the oxygen sensor (on V-engines, the heater of the right main oxygen sensor) |

| 29 | The additional oxygen sensor is faulty (right for V-engines) |

| 31 | Incorrect signal from the air flow sensor or, if there is none, from the pressure sensor in the intake manifold (vacuum sensor) |

| 32 | Incorrect signal from air flow sensor |

| 34 | Boost faulty |

| 35 | Incorrect signal from the atmospheric pressure sensor in the intake manifold (vacuum sensor) |

| 38 | Automatic transmission fluid temperature sensor |

| 41 | Incorrect signal from throttle position sensor (TPS) |

| 42 | Incorrect signal from the vehicle speed sensor (speedometer) |

| 43 | No starter signal (STA) to engine control unit |

| 46 | Solenoid valve number 4 or its circuits are faulty |

| 47 | The auxiliary throttle position sensor (TPS) or its circuit is faulty |

| 48 | The auxiliary air supply control system is faulty |

| 51 | No idle signal from TPS |

| 52 | Incorrect signal from the knock sensor (if there are two of them, then from the left or from the front) |

| 53 | Problems in knock sensor control circuits (ignition timing) |

| 55 | Incorrect signal from the knock sensor (if there are two of them, then from the right or from the rear) |

| 61 | The main speed sensor or its circuit is faulty |

| 62 | Solenoid valve number 1 or its circuits are faulty |

| 63 | Solenoid valve number 2 or its circuits are faulty |

| 64 | Solenoid valve number 3 or its circuits are faulty |

| 65 | Solenoid valve number 4 or its circuits are faulty |

| 67 | The O/D switch or its circuit is faulty |

| 71 | EGR control system faulty |

| 72 | Fuel cut solenoid |

| 77 | The pressure control solenoid or its circuit is faulty (in the machine) |

| 78 | There is no signal to the fuel pump or its circuits are faulty |

| 81 | The circuit between TCM and ECT1 is faulty |

| 82 | The circuit between TCM and ESA1 is faulty |

| 84 | The circuit between TCM and ESA2 is faulty |

| 85 | The circuit between TCM and ESA3 is faulty |

| 86 | Engine speed sensor is faulty |

| 88 | The circuit from the engine control unit to the automatic transmission control unit is faulty |

| 89 | Communication between the engine control unit and the TRC system control unit is broken |

| 99 | No fault codes |

The general list of unambiguous codes (type 10) for a Toyota car consists of the following items.

| Code | Decoding |

| 1 | No breakdowns |

| 2 | The air flow sensor gives an incorrect signal |

| 3 | Incorrect signal from the communicator |

| 4 | The coolant temperature is outside the normal range, the sensor has failed |

| 5 | Incorrect communication with the oxygen sensor |

| 6 | The fault lies in the number of engine revolutions |

| 7 | Throttle valve in incorrect position |

| 8 | The sensor shows incorrect intake air temperature |

| 9 | Car speed problem |

| 10 | There is no starter signal |

| 11 | The air conditioner is broken or the toggle switch responsible for the neutral position in the car is faulty |

Gasoline internal combustion engines

If the car has an on-board computer or robot, the code will appear on the mileage screen. It will consist of a Latin letter at the beginning, for example P, B, C, and 4 numbers. This is typical for cars such as Toyota Rav 4 Avensis, Corolla, Mark II or Land Cruiser 200, Toyota Prado 120 and others that run on gasoline.

Table for deciphering diagnostic fault codes for gasoline internal combustion engines.

| Codes | Decoding | Analogue on BC |

| 12 and 13 | Problems with the crankshaft position sensor | P0335, P0335, P1335 |

| 14 and 15 | Problems with the ignition system or coils | P1300 and P1315, P1305 and P1310 |

| 18 | VVT-i phase system | P1346 |

| 19 | Accelerator pedal position | P1120 and P1121 |

| 21 | Oxygen sensor | P0135 |

| 22 | Coolant temperature | P0115 |

| 24 | Damage to the intake air temperature sensor | P0110 |

| 25 | Oxygen sensor - lean mixture | P0171 |

| 31 | Absolute pressure sensor | P0105 and P0106 |

| 36 | CPS sensor | P1105 |

| 39 | VVT-i system | P1656 |

| 41 | Throttle position | P0120, P0121 |

| 42 | Vehicle speed sensor problems | P0500 |

| 49 | Fuel pressure D-4 | P0190, P0191 |

| 52 and 55 | Knock sensor failure | P0325 |

| 58 | SCV drive | P1415, P1416, P1653 |

| 59 | Incorrect VVT-i signal | P1349 |

| 71 | EGR system | P0401, P0403 |

| 89 | ETCS drive | P1125, P1126, P1127, P1128, P1129, P1633 |

| 92 | Cold start injector problems | P1210 |

| 97 | Injector faulty | P1215 |

Diesel engines

Many Toyota cars were produced with a diesel engine. The most popular models are the Vitz, Caldina, Avensis (T25), Camry, Camry Grazia, Corolla E150, Auris 2008 sedans, Land Cruiser Prado 120 and Land Cruiser Prado 200 SUVs or the RAV4 crossover.

When writing down codes for diesel cars, you can see the following symbols.

| Code | Decoding |

| 13 | Rotation speed is outside the permissible limits |

| 19 | Incorrect accelerator pedal position |

| 22 | Malfunction in coolant temperature indicators |

| 24 | Incorrect intake air temperature data |

| 35 | Boost pressure is out of range |

| 39 | Fuel temperature sensors do not work well |

| 42 | The fault lies in the vehicle speed sensor |

| 96 | EGR valve position is incorrect |

Failure of other diesel engine parts.

| Code | Decoding |

| 12 | Crankshaft position problem |

| 14 | Damage to the valve that regulates the injection advance angle |

| 15 | The throttle servo is faulty |

| 17 | Incorrect signal coming from the control unit |

| 18 | Damage to the solenoid bypass valve |

| 32 | Failure of correction resistors |

Automatic transmission

Cars of the same brand differ not only in the engine, but also in the gearbox. For the same Toyota Corolla 150, Celsior or Vista, automatic transmission failures will differ from mechanical failures.

If there is a malfunction in the transmission, you will see one of the codes.

| Code | Decoding | Analogue for automatic transmission |

| 37 | Transmission input shaft speed sensor malfunction | P1705 |

| 42, 44, 36 | The problem is in the speed sensor (maybe shaft speed) | P0500 |

| 46 | Accumulator pressure, solenoid faulty | P1765 |

| 62, 63 | Problems with one of the solenoids | P0753 P0758 |

| 64, 68 | Torque converter lock-up clutch, solenoid faulty | P0773 |

Such errors are typical for different models, including Toyota Ipsum, Toyota Highlander 2001 and Caldina.

Other combinations

Special equipment and devices are also used for diagnostics. Such devices will show five-digit codes. They can also be recognized using the on-board computer, which is installed in new cars and hybrid models.

Code on the Toyota screen with on-board computer

Toyota Estima, Toyota Prius, third generation Toyota Harrier and others came out in the hybrid version. These models (in addition to other breakdowns) may experience malfunctions of the high-voltage battery system (HVB). Hybrid installation error codes and their interpretations are given in the table.

The most common non-VVB error codes are:

| Code | Decoding |

| P1604 | Engine starting failed, failure in the intake system |

| B0101 | The security system does not work correctly, there are problems with the airbags |

| In 1801 | The squib circuits on the driver's side are broken. |

| C1201 | Engine operation is incorrect, speed is below the permissible level |

| P0420 | Catalyst system B1 operates below the permissible efficiency threshold |

| P0352З | Problems in the ignition system circuits |

The photo gallery shows errors in the operation of the immobilizer and tires on Toyota cars.

Errors in the operation of the immobilizer Errors in the operation of tires

The most common 5 reasons for the error

The most common problems when this error occurs are:

Let's look at each of the reasons in a little more detail. The oxygen sensor is part of the system that processes exhaust gases. This sensor helps control fuel consumption. A malfunction of this sensor is taken as an engine malfunction. That is, the system cannot accurately calculate the fuel supply level and this is precisely why the error occurs. Most Corolla models have from 2 to 4 such sensors, so we should know that an error due to them is possible.

The next option is a loosely sealed fuel tank. On the tank neck of any modern car there is a sensor that is responsible for the tightness of its closure. So if the neck is not closed tightly, the car's computer accepts this as an engine error. Therefore, before suffering from a malfunction, it is worth checking the cover.

The third option may be an exhaust gas catalyst. When it becomes unusable, the car's engine loses its power and due to this, the car's computer may also show an error, since loss of power is a good reason for turning on the error. Loss means some kind of malfunction.

The air flow sensor regulates the amount of air supplied to the fuel for further launch into the engine cylinders. A faulty air supply sensor can lead to an increase in fuel consumption, as well as a decrease in engine power, so the on-board computer may consider this malfunction as an engine error.

Failed spark plugs can also be one of the causes of engine malfunction. The process of incorrect ignition in the engine cylinders usually leads to an error that is generated by the computer. Replacing the spark plugs or adjusting them can correct the problem and eliminate the computer error.

These are the main reasons why the “Check engine” or “Check engine” error appears on a Toyota Corolla. However, to more accurately clarify the problem, we can use self-diagnosis.

Reset errors

After the repair has been made and the breakdown has been fixed, the error codes may not disappear on their own. There is also a certain sequence of actions to reset them. To do this, we again need a diagnostic connector.

To reset codes you need to:

- Turn on the ignition.

- At the DLC1 connector, short-circuit the TC and E1 terminals with a piece of wire or wire.

- In 3 seconds, press the brake as many times as possible, but not less than 8.

- Make sure the light blinks evenly at half-second intervals.

- Turn off the ignition and remove the jumper from the contacts.

- Make sure that the ABS indicator does not light up.

“Artem0023” explains in the video how to carry out self-diagnosis of Toyota cars step by step:

To start the engine, the driver turns on the ignition. If the check engine light is flashing at the same time, this should not cause concern, since it will soon go out. But a burning signal while the engine is running indicates problems with its operation.

If a malfunction occurs in the operation of the power unit, an error is recorded in the memory of the control unit in the form of a coded signal. In this case, the check engine light appears on the dashboard. If the car does not have diagnostics in automatic mode, you need to connect a scanning device to a special connector. The scanner reads the code and provides a detailed explanation of the error.

With the development of electronics, the Check Engine indicator has evolved from a simple fault sensor into a warning lamp with many functions. When a modern check engine light flashes, it reports the following inconsistencies:

- incorrect composition of fuel mixtures;

- settings failures in the ignition system;

- sensor failures.

His duties also include reporting problems not related to the power unit. To identify the location and nature of the breakdown, the technician will need professional knowledge, experience, special devices and tools.

Important: The ECU electronic unit commands the indicator to flash as a result of detecting errors of varying degrees of complexity. Among them there are problems both serious and minor. In order to carry out diagnostics, it is recommended to suspend operation of the vehicle. Experienced car owners often independently determine the reason for the inclusion of a check, without waiting for a visit to the service station.

Main errors of Toyota Auris: Diagnostics, elimination and prevention

Diagnostics using a scanner in Toyota Auris produces OBD 2 error codes, which are indicated by five characters. Check Check Toyota Auris Engine One of the main links in the car's electrical system is sensors. They are the first to respond to detected problems. Malfunctions of the sensors lead to the fact that the sensor itself switches to an emergency mode of operation or to a complete stop of a particular component of the car.

After adding engine oil and warming up the engine, the check engine indicator does not light up , which means you can continue driving without a speed limit.

Toyota Corolla steering rack - design

A mechanical assembly consisting of a gear is designed to convert the rotation of the steering wheel into horizontal deflection of the vehicle's front wheels. The design itself consists of several elements, the coordinated work of which ensures the movement of the vehicle:

- Frame. Designed to accommodate the component parts of the unit. The body material in modern passenger cars can be made of steel, aluminum or duralumin. The hydraulic cylinder is located either inside or outside the steering rack housing.

- Shaft. For the manufacture of the shaft, high-strength steel is used, the surface layer of which undergoes a cementing procedure. Thanks to the shaft, power is transmitted to the wheels.

- Support bushings. To keep the shaft from distortion, special bushings are used. They fix the device, centering it in the body.

- Distributor. When turning the steering wheel, force must be transmitted in a certain direction. To do this, you need a distributor, through which the flow of hydraulic fluid is directed to the required compartment of the hydraulic cylinder.

- Bearings. The rotation of the elements in the housing is ensured by bearings.

- Pistons. The hydraulic fluid pressure is transmitted to the steering shaft by the pistons.

- Oil seals. Sealing elements are used to retain hydraulic fluid inside the device. They transfer fluid flow to the desired compartment of the hydraulic cylinder, preventing it from moving into other cavities.

- Clamping mechanism. Required to keep the shaft from moving and regulates the force.

- Hydraulic bolts. Fixation of the support bushings and the clamping mechanism is ensured by the presence of locking rings, springs, and hydraulic bolts.

- Rings made of rubber and Teflon. These elements are used to seal all rack units.

Checking the oil level and condition

The next most important reasons for the signal are considered to be overheating of the motor and a decrease in the level of lubricating fluid in the internal combustion engine. It is recommended to check the engine temperature. If there is no overheating, you need to check the volume and condition of the oil. After checking the level, it is necessary to add the missing amount of lubricant. Using a clean paper napkin, the quality and composition of the engine oil is checked according to the following criteria:

- Color.

- Consistency.

- Presence of mechanical inclusions.

- The smell of burning.

If everything is in order with the quality and quantity of oil, the engine starts to eliminate unusual sounds and noise when operating both at idle and under load.

Specifications

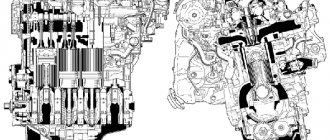

The narrow scope of application dictated the conditions that the characteristics of the 1ZR-FE had to meet. In numerical terms, the unit’s indicators look like this:

| Working volume | 1.6 liters |

| Maximum power | 124 hp achieved at 6000 rpm |

| Torque | 157 N*m at 5200 rpm |

| Number of cylinders | 4 |

| Number of valves | 16 |

| Cylinder diameter | 80.5 mm |

| Piston stroke | 78.5 mm |

| Gas distribution system | DOHC |

| Compression ratio | 10.2:1 |

With a reduced piston stroke, the power remained quite large. This combination of characteristics made the engines potentially more reliable. The resource of 1ZR-FE is about 400 thousand kilometers. At the same time, it is impossible to make a major overhaul of the piston system - the thin-walled cylinder block and the lack of repair dimensions make this resource the end of its service life.

The Toyota 1ZR-FE engine has unusual operating characteristics. At low speeds, the car's dynamics are not very impressive, but in highway mode, overtaking can be accomplished without difficulty, even from high speeds.

Main faults of Toyota Corolla

The high popularity of the Corolla model, developed by Japanese designers of the Toyota concern, is well deserved. This presentable, luxurious car is able to satisfy the most fastidious admirer of comfort and easy operation. An important advantage of these machines is reliability, which is guaranteed by the high quality of parts and components and impeccable assembly. But in our extreme conditions, Toyota Corolla malfunctions are still possible. It is advisable for owners to know the weak points of their car. Since Toyota repairs are expensive, you need to reduce the risk of breakdowns.

Flashing indicator and engine tripping

When the check engine light flashes and the engine starts at the same time, it is necessary to inspect the elements of the ignition system:

- spark plug;

- wiring;

- coil.

The tripling effect occurs when only three combustion chambers are firing instead of all four. The engine begins to stall when there is no injection of the air-fuel mixture into one cylinder.

Worn out and dirty spark plugs can also cause the Check Engine light to turn on. In order not to think for a long time about how to remove the check engine light, you just need to clean or completely replace the outdated spark plugs with a new set.

Check Engine light is on (engine error): causes and best solutions to the problem

Experienced drivers and auto mechanics believe that you can drive to a service station under your own power in the following cases: In expensive foreign cars, clogged injectors on each cylinder can be tracked using the personal self-diagnosis code of the on-board computer. Track repairs and cleaning of injectors in a garage are impossible, as they require complex disassembly and assembly operations of the fuel rail.

- As in the previous case, make sure that the handle is turned to the right all the way.

- Then turn on the ignition without starting the engine.

- The mode selector also needs to be turned all the way clockwise.

What to do if the check engine light comes on due to a malfunction in the fuel supply system

In case of problems associated with the flow of fuel into the cylinders, it is recommended to check the condition of the spray nozzles. Their holes must be cleaned, washed, and, if necessary, completely replaced with new devices.

A decrease in pressure in the fuel system is caused by malfunctions:

- Gasoline pump (in carburetor, injection engines).

- Fuel filter

- Injection pump pump (in diesel).

If the check light is caused by a failed catalytic converter, drivers simply remove it from the exhaust system and then disconnect the corresponding sensor (oxygen).

1ZRFE Service Regulations

Since the motor can quickly fail and major repairs will no longer help it, you should follow the maintenance schedule. For example, experienced mechanics recommend changing the oil every 10 thousand kilometers. For Russia, only 5W20 and 5W30 lubricants are used. Since they can withstand quite low temperatures.

Attention! To change the lubricant you will need 4.2 liters of engine oil. And the total volume is 4.7 liters.

Since the timing belt is a chain one, it is recommended to change the chain every 100 thousand kilometers. The chain should be inspected once every 50,000 kilometers in order to detect chips or other minor damage in time. Because a broken chain will cause irreversible damage to the 1 ZRFE engine.

The air filter is changed after 30 thousand kilometers, and the fuel filter after 80 thousand kilometers. New spark plugs are installed after 40 thousand kilometers. Antifreeze is changed every five years. The coolant is enough for one hundred thousand kilometers of the car.

The auxiliary belt is changed after 100 thousand kilometers. But adjustment of the thermal clearances of the valves is not provided.