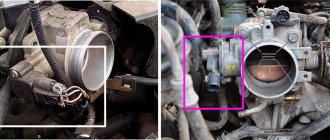

The development of technology has provided not only convenient and economical ways to travel, but also quick ways to diagnose car breakdowns. One of these methods is Toyota error numbering, which shows a malfunction in a particular unit or part. Toyota engine error 31 indicates a faulty absolute pressure sensor. Almost all engines that do not use an air flow sensor are equipped with it.

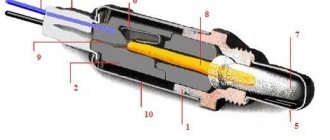

The Toyota engine absolute pressure sensor converts the pressure readings received from the input fitting into a corresponding voltage value at the output. Inside it there is a special chamber from which, during the production process, all air was completely pumped out to create a vacuum. This device compares the pressure at the fitting with the pressure directly in the chamber and, based on the data obtained, issues a certain signal.

In most cases, as the pressure in the intake manifold decreases, the voltage output by the sensor at the outlet decreases proportionally. Information about the amount of pressure inside the device allows the computer that controls the engine to calculate how much air enters the internal combustion chamber and the necessary amount of fuel that the injectors should produce. Typically, such sensors are installed on those engines that do not have mass air flow sensors, since they are mutually exclusive due to different operating techniques.

Description of errors P0031 P0032

See page error P2195.

NOTE:

- Although the error codes indicate the oxygen sensor, these codes refer to the air-fuel ratio (A/F) sensor.

- Sensor 1 refers to the sensor mounted at the front of the three-way catalytic converter (TWC) and located near the engine.

- When any of the following codes are detected, the ECM enters limp mode. In emergency mode, the ECM turns off the A/F sensor heater. Emergency operation continues until the ignition is turned off.

The ECM controls the amount of current through the heater using a pulse width modulation signal. A relay on the +B side of the circuit is used to control the A/F sensor heater circuit.

| No. Errors | Error detection condition | Faulty area |

| error P0031 | Air-fuel ratio (A/F) sensor heater current is less than 0.8A (1 trip detection logic) |

|

| error P0032 | Air-fuel ratio (A/F) sensor heater current exceeds 10 A (1 trip diagnostic logic) |

|

Replacing the sensor

DAD with number 89420-02010

If the diagnostics showed a malfunction of the device, then it can only be replaced with a new one.

A used sensor on the Russian market will cost a car enthusiast about 1,500 rubles, however, there is no guarantee that it will be fully operational. To ensure that you receive a quality part, you should contact an official representative of Toyota or use the search on the company’s website where you need to indicate the following catalog code of the form: 89420-02010 (suitable for engines 4A-FE, 7A-FE, 4E-FE). If there is no available funds, then you can always find cheaper domestic analogues, but there is no guarantee of their quality.

Description of error logging P0031 P0032

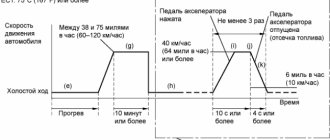

The ECM uses signals from the air-fuel ratio (A/F) sensor to regulate and maintain the air-fuel ratio at a near-stoichiometric level. This increases the three-way catalytic converter's (TWC) ability to clean exhaust gases. The A/F sensor detects the level of oxygen in the exhaust gases and transmits information about it to the ECM. Ambient air passes along the inner surface of the sensing element. Exhaust gases pass along the outer surface of the sensing element. The sensing element is made of platinum-coated zirconium and has a built-in heating element. When there is a significant difference in the oxygen content in the exhaust gases and the surrounding air, the zirconium element generates weak voltage signals. The platinum coating enhances this tension. When warmed up, the A/F sensor's efficiency increases. At low exhaust gas temperatures, the sensor cannot generate useful voltage signals without additional heating. The ECM controls the degree of heating by controlling the duration of activation by adjusting the flow of current to the sensor heating element. If the heater current is outside the rated range, the accuracy of the A/F sensor signal is reduced and, as a result, the ECM cannot properly adjust the air-fuel ratio. If the current in the A/F sensor heater is outside the operating range, the ECM perceives this as a malfunction and registers an error. For example: The ECM will set a P0032 fault code if the A/F sensor heater current is greater than 10 A. Conversely, if the heater current is less than 0.8 A, a P0031 fault code will be set.

Toyota distributor repair in Moscow: addresses of technical centers

1,066 auto repair centers

- Stoa

- Novofedorovskoe settlement, block No. 135, Torgovaya Square, 12, building 1

- +7

- daily, 09:00–22:00

3.2 4 ratings

- My Motor Service

4.6 18 ratings

- Service-Krylatskoe

5.0 138 ratings

- Avtomakina

4.1 25 ratings

- Express oil change

5.0 3 ratings

- Autopilot

4.7 40 ratings

- Soundauto

4.7 16 ratings

- BenzBMW

4.5 48 ratings

- Vianor

4.7 23 ratings

- Volvo

5.0 42 ratings

- Gadget

4.6 18 ratings

- JapGarage

3.9 26 ratings

1 107 Show car services on the map

How to change the oil in an automatic transmission Toyota Corona/Caldina

Removed automatic transmission pan Toyota Corona 1.8(A245E)

To replace you will need:

- inspection hole or overpass;

- keys with a head for 14 and 10;

- transmission oil;

- automatic transmission filter;

- automatic transmission pan gasket;

- funnel according to the size of the probe;

- container for draining waste.

We go down into the pit and start replacing:

- We unscrew the drain plug in the automatic transmission pan with a 14mm head, substitute the prepared container and drain the oil.

- We measure the amount of oil drained (so that later the same amount can be added if a partial replacement is made).

- Remove the crankcase protection by unscrewing 7 bolts with a 10mm head.

- We unscrew all the bolts (the number may vary depending on the model) around the perimeter of the automatic transmission pan and carefully remove it (there will be oil in it, it should be poured into the same container in which we measure the drained amount).

- We clean the removed pan and rinse it with gasoline, then wipe it dry.

- There are two magnets on the pallet; they need to be cleaned of shavings and stuck back on the clean pallet.

- Unscrew and replace the automatic transmission filter (located under the pan, secured with 3 10mm bolts, it will also contain a little fluid that should be drained).

- Place the pan in place and tighten the drain plug.

- We insert a funnel into the dipstick hole and fill in fresh liquid (the same amount as drained, taking into account in the pan and filter).

- Start the engine at idle speed and move the selector to all positions from “P” to “L” and back to “P” and so on several times.

- At normal operating temperature 70-80 degrees, check the oil level and add if necessary.

Maintenance regulations

3S-FE engines after 1996 cannot be repaired; they are disposable, but with a long service life. Therefore, new Toyota S series engines, that is, after ’96, should be serviced on time, efficiently and using high-quality consumables.

Table of consumables for timely replacement:

| Details | Time or mileage (whichever comes first) |

| Timing belt | replacement after 100,000 km |

| Accumulator battery | 1 year or 20,000 km |

| Valve clearances | 2 years or 20,000 km |

| Crankcase ventilation | 2 years or 20,000 km |

| Belts that drive attachments | 2 years or 20,000 km |

| Fuel hoses and tank cap | 2 years or 40,000 km |

| Motor oil | 1 year or 10000 |

| Oil filter | 1 year/10000 |

| Air filter | 1 – 2 years/40000 |

| Fuel filter | 4 years/40000 |

| Heating/Cooling Fittings and Hoses | 2 years/40000 |

| Coolant | 2 years/40000 |

| Oxygen sensor | 100000 |

| Spark plug | 1 – 2 years/20000 |

| Exhaust manifold | 1 year |

It would be a good idea to use your own manual for each car model. Each model has its own standards and replacement time.

“Fighting” error 14

There are a number of ways to install a non-working coil:

- if the engine is running rough, then by disconnecting the coil connectors, you can notice either a decrease in speed (the part is intact), or they will remain the same (defective part);

- On the removed coils, measure the resistance of the windings; usually faulty ones have a sharply different resistance. And a spark plug paired with a damaged coil is usually wet and black with soot;

- Sometimes a car’s self-diagnosis can show which cylinder is not working when the “Check engine” indicator is on.

Auto centers identify faulty parts using motor scanners that analyze vehicle electronics.

Troubleshooting (misfire) may be related to the coil tips. In this case, they must be replaced immediately. Otherwise, it may even break through the control transistor or short-circuit the secondary winding.

The malfunction of the coil itself is often associated with its primary winding, which requires its replacement. In this case, it is necessary to ensure complete insulation of the wires.

“Temper” of error and “behavior” of the motor

When the car has one ignition coil, then if it breaks down, you will not be able to drive further until the problem is fixed or replaced. But since modern engines have as many of them as there are cylinders, you can still go some way with this error. However, the engine will start:

- triple and this problem will only continue to grow;

- do not “feel” the gas pedal, i.e. the speed will not increase and may even fall;

- when it rains, the tripling will be greater;

- in the cold since the start.

Basically, ignition coils can fail when:

- installing bad spark plugs that allow breakthrough of reverse gases and breakdown of the insulator, which is bad for the insulators of the ignition coils;

- overheating for a long time if the cooling system is faulty or the fuel mixture is very lean. It also ruins the spark plug tips and coil electronics.

What error 14 Toyota can lead to:

- melting of the gas catalyst-neutralizer;

- rapid wear of the motor mounting pads due to high vibration;

- excessive fuel consumption, loss of power and engine efficiency.

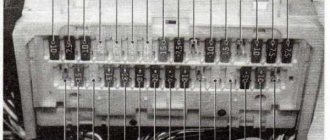

Error code 14

Error codes are read by the number of flashes of the Check engine indicator when terminals TE1 - E1 on the DLC1 connector in the engine compartment or TC - CG connector DLC3 under the dashboard are closed when the ignition is on. On premium cars they will be displayed on a special display on the dashboard.

Toyota engine error code 14 indicates a malfunction of ignition coils No. 1 (P1300) and No. 4 (P1315) . Moreover, both the coils themselves and the Electronic Control Module, as well as wiring and connectors, including power supply circuits, can fail.

3s FE device

Since with not very high developed power and with a volume of 2 liters, the 3 C FE engine has a long overhaul life. Modern models of injection engines with the same volume produce much more power, which is why they have a shorter service life. And this Toyota engine, 3S-fe, does not wear out, and produces normal performance without straining. Of course, those who love cars with high power will not look at this engine.

The main operational indicators of the ICE 3s fe produced before 1996 have the following values:

- The volume of the power unit is 2.0 liters with the Twin Camshaft system;

- Engine power - 128 hp. = 94 kilowatts at a crankshaft torque of 5600 rpm;

- Torque - 179 N*m (Newton per meter) at 4400 rpm.

- The fuel injection system is electronic.

In addition to the fact that this modification of the Toyota S series motor operates in quiet mode, it has a long service life due to the absence of a complex system and electronic elements.

- 1 – accelerator cable;

- 2 – throttle valve control cable (automatic transmission);

- 3 – bracket;

- 4 – high-voltage wires;

- 5 – safety sleeve;

- 6 – cylinder head cover;

- 7 – gasket;

- 8 – camshaft No. 1 (intake valves);

- 9 – camshaft No. 2 (exhaust valves);

- 10 – camshaft bearing cover;

- 11 – oil seal;

- 12 – internal combustion engine camshaft pulley;

- 13 – cover No. 2 of the timing belt;

- 14 – tensioner spring;

- 15 – tension roller;

- 16 – collector stand;

- 17 – brake booster vacuum hose;

- 18 – vacuum hose of the absolute pressure sensor;

- 19 – air filter cover with air duct;

- 20 – inlet fuel hose;

- 21 – heater inlet hose;

- 22 – radiator inlet hose;

- 23 – cylinder head assembly;

- 24 – coolant bypass hose No. 1;

- 25 – coolant bypass hose No. 2;

- 26 – gasket;

- 27 – exhaust pipe;

- 28 – gasket;

- 29 – generator;

- 30 – power steering vacuum hose

When they came up with electronic fuel supply to the working chambers of internal combustion engine cylinders, the 3S-FE injection version was developed. Thanks to good design characteristics, almost all Toyota models of 1997-2201 were equipped with 3S series engines.

Millionaire engines, that is, the most reliable and durable engines (can run 1 million kilometers without major repairs), include all models of S3 engines. Of course, this can only be achieved with regular maintenance and the use of high-quality fuels and lubricants.

How to check the oil level in an automatic transmission?

- Before you start diagnosing Toyota Corona/Caldina, you should warm up the engine. To do this, you need to drive a short distance until the temperature of the working fluid reaches 70-80 degrees Celsius.

- The next step is to install the machine on a flat surface. It doesn’t matter whether it’s a garage or a lawn, the main thing is that it doesn’t slope.

- Apply the parking brake.

- At idle speed, select all selector positions one by one (while holding the brake pedal).

- Carefully remove the dipstick to clear it of oil and then completely immerse it in the pipe.

- After the next time you remove the dipstick, you can determine the level of working fluid in the automatic transmission. It is considered normal if it is located next to the HOT marks.

During the inspection, anomalies can be detected in the smell of the oil, its appearance and properties. If the liquid has a dark tint, gives off a burning smell, or has become too viscous, then it must be replaced. Regular topping up will not correct the situation.

You can get acquainted with the procedure for changing the oil in a Toyota Corona/Caldina automatic transmission in a special manual. It contains additional recommendations that will help you choose the type of oil and introduce you to important nuances.

Video

This video shows the analysis of the 3S-fe engine. Part 1.

Analysis of the 3-s-fe engine. Part 2.

Launch after a complete overhaul of a 3S-FE Toyota car.

And this video provides a list of the best engines, Top 5. Millionaire engines.

How to replace the cylinder head gasket on a Toyota Vista SV30 (Toyota Vista) with a 3s-fe engine.

How the motor should work. Correct sound.

Diesel sound of the 3S-FE engine. Where?

0

Author of the publication

offline 1 month

Catalog numbers

Ignition coil You must always monitor the catalog numbers of the Toyota ignition module and make changes in time, since outdated models are no longer produced, but new ones appear.

These important components of the Toyota ignition system (like all others) have a ten-digit catalog number. The first five are the same for all coils - 90919, the next five (usually written with a dash) are different, for example, 02117, 02163, 02234, 02259, 02265, etc.

Considering the important role that this module plays, it would be correct not to experiment with installing suitable coils on the machine, but to install only the one recommended by the manufacturer.