Items you will need

- Hydraulic jack

- Jack is standing

- Iron tires

- Box wrench for bleeding bolt

- Turkey buster

- Transparent plastic bottle

- Clear plastic tube

- Brake fluid

Air inside the brake system is a potentially catastrophic problem. Loss of brake pressure caused by air in the system results in reduced braking power and poor brake performance, which can lead to accidents. Bleeding your brakes will restore brake pressure and significantly increase your vehicle's stopping power. Bleeding the brake lines should always be done at the same time as changing the brake fluid, which will be included in this manual.

Use a jack to raise the car onto 4 stands.

Use a tire iron to remove the bolts on each wheel, and then remove the wheels.

Loosen the bleeder bolts on each wheel using a socket wrench, being careful not to open the bleeders yet. If the slots are very difficult to open, you may need to apply some penetrating oil to them and leave them for a few hours or even overnight.

Open the hood of the car and open the master cylinder reservoir.

Use the turkey baster to remove as much oil from the reservoir as possible.

Clean the inside of the tank with a clean cloth.

Fill the reservoir with new brake fluid and close it.

Place a piece of clear plastic tubing around the wheel bleeder valve, starting with the right rear wheel.

Place the other end of the tube into a clear plastic bottle that is 1/4 full of clean brake fluid. Make sure the tubes are immersed and remain immersed in the liquid.

Have someone press on the brake pedal while you open the bleeder bolt slightly.

Have them apply the brake about 3/4 of the way and hold it while the old brake fluid drains down the plastic line.

As soon as the fluid flow stops, close the bleeder bolt with a wrench and have an assistant release the brake pedal.

Continue doing this until clear fluid begins to flow out of the bleeder valve, remembering to refill the master cylinder reservoir every 3 times, performing process 10 to 12.

Repeat steps 8 through 13 for each wheel, starting with the right rear wheel, then moving to the left rear wheel, right front wheel, and finally the left front wheel.

Top up the master cylinder reservoir.

Screw the wheels back into place.

Lower the car from the jack.

Installation of front Z brakes Toyota Corolla Fielder E120

Watch how to turn off the brakes on a Toyota Corolla

Have you just purchased a new Toyota Corolla? Or maybe not at all and I'm carrying this car for a long time. All this is not very important, because both a novice and an experienced driver can encounter problems with the brakes. But how to bleed the brakes on a Toyota Corolla .

Meanwhile, following certain instructions is not that difficult.

One important rule when pumping is to proceed with caution. brake fluid, which should not get into the eyes, on the skin, or on the painted surfaces of the car itself. Additionally, avoid contact with hot chambers or open flames as the liquid is flammable. Its reuse is also strictly prohibited.

Types of ABS system on Toyota cars

There can be two of them, with differences in design and pumping methods:

- ABS consists of a hydraulic valve block, a pump and a hydraulic accumulator. Such a system can be very easily pumped even in your own garage;

- All of the above elements are placed in different blocks, with additional modules, and are pumped only in a service station. You will need a diagnostic scanner to monitor the modulator valves.

Taking into account these features, you can understand that first of all you should find out the type of ABS for each specific Toyota car model. The fact is that the following instructions will only be relevant for its standard version.

The process of replacing brake hoses on a car

Replacing the brake hoses itself is not difficult; I did not change the washers under the hoses, which in theory should be copper, I installed the old ones, which I had were aluminum, double ones. Before unscrewing the hoses, we treat all connections with WD40.

Processing connections with WD40

Next, loosen the bolt connections a little and pull out the brake hose retaining bracket.

Loosen the brake system tube and pull out the locking bracket.

Then we finally unscrew all the connections and install new brake hoses. And tighten it with the force specified in the auto instructions.

For models with conventional brake system

Repeat the procedure for the front of the second circuit master cylinder. To prevent fluid from escaping from the cylinder and, therefore, air entering it, before removing the plugs, have an assistant lightly press the brake pedal approximately 30 mm and hold it in this position.

Remove the plugs from the brake pipes and make sure that both pipes are filled with fluid; if not, add liquid to them. Quickly remove one of the master cylinder plugs and hold the brake pedal as described in the previous paragraph, connect the brake pipe and tighten the connecting nut to the torque specified in the Specifications.

Repeat the procedure on the second master cylinder port, then wash off the spilled fluid.

Refer to the paragraphs above and completely bleed the brake hydraulic system in the above sequence. In the opposite situation, the pressure on the brake pedal is not transmitted to the brake calipers or wheel cylinders.

Contamination of a liquid causes it to become compressible. This results in a soft feeling when applying the brakes, which can eventually lead to complete dysfunction. To troubleshoot problems, you will need the help of an assistant, since performing some actions at the same time alone is simply impossible.

Place the car on a level surface, and after turning off the engine, move the gear shift lever to the reverse or first gear position. Support the wheels and release the handbrake. After removing the master cylinder or if the reservoir was empty, the air must be removed from it. Air can also enter when the amount of working fluid is below the minimum level.

Remove the brake pipes from the master cylinder 5. Smoothly press and hold the brake pedal 6. Plug the cylinder outlet holes with your fingers and release the brake. Repeat the steps once. Bleeding begins with the longest brake line. If possible, it is recommended to use one of these kits when bleeding the brakes, as they greatly facilitate the procedure and also reduce the risk of air and old brake fluid expelled from it getting back into the system.

If it is not possible to use such a kit, you should use the basic two-person brake bleeding method, which is described in detail below. When using a brake bleeding kit, prepare the vehicle as described above and then follow the kit manufacturer's instructions, as the procedure may vary slightly with different kits.

Typically, the procedure is carried out according to the scheme given below in the corresponding subsection. It is possible to partially bleed the brake system, that is, only one brake line and caliper at a time. This may be sufficient if only one circuit is open for work, but it is much safer, and therefore preferable, to completely bleed the system.

A description of the brake fluid replacement procedure is given in the Routine Maintenance Chapter. Pumping procedure For pumping you will need the help of an assistant. The choice of order in which to bleed the brake lines is not fundamentally important, since each caliper has its own connection to the master cylinder.

Prepare a clean glass container, a suitable piece of plastic or rubber tubing that fits tightly over the brake bleeder valve, and a socket wrench of the same size as the valve. Alternatively, have a proprietary brake bleeding kit available for use.

Remove the boot cap from the bleeder valve of the first caliper. Place a socket wrench on the valve head, then pull the drain tube onto the valve nipple. Place the other end of the tube into a glass container and add a small amount of brake fluid into the container, enough to cover the lower end of the tube. During the procedure, monitor the liquid level in the reservoir and do not allow it to drop below the minimum mark; If necessary, add brake fluid.

Have the assistant press the brake pedal several times to increase the pressure in the system - then keep the pedal pressed during the final pumping motion. After the system pressure has risen, loosen the valve approximately one turn and allow the liquid to flow into the glass container.

During the procedure, the pedal must be used to maintain pressure in the system; If necessary, depress the brake pedal all the way, but do not release it. After the fluid stops flowing out, tighten the valve, after which the assistant can slowly release the pedal. Check the fluid level in the reservoir and add it if necessary.

If there was air in the brake system, it will be noticeable in the form of bubbles in the fluid leaving the system.

Repeat the procedures described in the previous two paragraphs until the liquid flowing from the valve no longer contains air bubbles. If the master cylinder has been drained and refilled with new fluid and the first brake line has been bled, wait approximately 5 seconds between cycles to refill the master cylinder passages.

Re: bleeding brakes on a 2008 Toyota Corolla.

After air bubbles stop appearing, tighten the valve firmly, then remove the tube and key and replace the boot cap. Repeat the procedures with the remaining brake lines until the air is completely expelled from the system and the brake pedal feels firm again. Bleeding the Brake System Using a Check Valve Kit As its name suggests, the kit consists of a piece of tubing equipped with a check valve that prevents the air and hydraulic fluid pumped out from flowing back into the system; Some kits include translucent containers that can be positioned so that air bubbles coming out of the end of the drain tube are clearly visible.

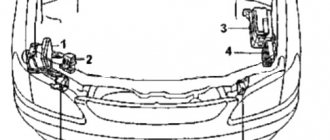

Hydraulic brake system Toyota Corolla

Bleeding sequence If components of only one of the circuits have been disconnected or removed, such as a caliper or brake wheel cylinder, only this circuit needs bleeding. If the entire system needs to be bled, proceed in the following sequence: Prepare a clean glass reservoir, a suitable length of plastic or a tube that fits tightly onto the bleeder fitting.

Help from a second person will be required. If not already done, remove the dust cap of the bleeder fitting and place the tube prepared for bleeding onto the fitting. Immerse the other end of the tube in the brake fluid previously poured into the reservoir. Have an assistant press the brake pedal all the way down several times and then hold it down. Open the bleeder fitting for bleeding the Toyota Corolla 2008 brakes one turn, see the accompanying illustration.

When fluid stops flowing from the fitting, tighten it and have an assistant slowly release the pedal and check the fluid level in the master cylinder reservoir.

Repeat this procedure, paragraphs 4 and 5, until the leaking brake fluid is free of bubbles. If all the fluid has drained from the master cylinder while bleeding the first brake, fill the master cylinder and bleed the brake again, taking approximately five seconds between cycles.

Tighten the bleeder fitting, remove the plastic tube and install the dust cap. Repeat the procedure on the remaining brake mechanisms in the above sequence. These devices are a Toyota Corolla 2008 brake bleeder pipe with a non-return valve that prevents the air and liquid that has escaped from being drawn back into the system. When the brake is released, the piston is moved away from the pad due to the elasticity of the sealing ring, resulting in a small gap being formed between the pads and the disc.

The front chamber is connected to the right front and left rear brake mechanisms, the rear chamber is connected to the left front and right rear. A tank 1 is installed on the main cylinder, the internal cavity of which is divided by partitions into two compartments. Each compartment feeds one of the brake master cylinder chambers. When you press the brake pedal, the pistons of the master brake cylinder begin to move, the working edges of the cuffs block the compensation holes, the chambers and the reservoir are separated, and the displacement of brake fluid begins.

Repair of the brake system of Toyota Corolla (Toyota Corolla)

Our “RS Auto Service” carries out all repair and testing work to adjust the performance of the car, which includes repair of the Toyota Corolla brake system.

In most cases, a breakdown of the brake system manifests itself quite acutely and even becomes the cause of a dangerous situation on the road. However, if you carefully handle the car, you can notice that the brake is not working properly based on characteristic signs.

Specific signs of a malfunctioning braking system:

- The brake pedal is wobbling or feels loose.

- Brake pedal slipping.

- The car pulls to the side when the brake is pressed.

- Creaking noise when braking.

- Brake fluid leak.

- Increasing the duration of braking.

- Uneven pad wear.

If similar failures occur even once, it is important to contact the specialists of RS Auto Service, who will quickly identify the problem and repair the Toyota Corolla brakes. The experience of our technical center technicians shows that brake damage is often caused by wear of one of its components.

In such situations, it may be advisable to repair the brake caliper, replace the master, front or rear brake cylinder of Toyota Corolla (Toyota Corolla)

The experience of our technical center technicians shows that brake damage is often caused by wear of any of its components. In such situations, it may be advisable to repair the brake caliper, replace the master, front or rear brake cylinder of Toyota Corolla (Toyota Corolla).

The use of high-quality components by our specialists in processes such as replacing a Toyota Corolla caliper or replacing a cylinder creates reliable repairs.

Repair of the Toyota Corolla brake system is carried out in several important stages. The technically difficult stage of repairing the brake system is replacing its components.

Work that includes repairing Toyota Corolla brakes:

- Checking the entire node in general.

- Replacing the caliper.

- Changing the cylinder.

- System installation.

- Bleeding the brakes.

A professionally performed replacement of the Toyota Corolla brake caliper and replacement of the brake cylinder provide the car owner with the most important thing - driving safety.

From the success story of the legendary Toyota Corolla

Toyota Corolla is included in the Book of Records as the most popular car. Entering the market since 1966, the model tried different options: hatchbacks, sedans, station wagons, liftbacks.

To date, Toyota Corolla has retained its characteristic appearance and technical features at a high level. These include a reliable anti-corrosion coating and an impeccable installation method.

In addition, the Toyota Corolla collects good marks in equipment safety testing.

We have a guarantee for all work and spare parts purchased in our technical center.

We will be glad to see you at our car service center in Kupchino! If you have any questions, please call +7(812)6122842

Bleeding the brakes

This circumstance allows you to freely use the work, while respecting personal non-property rights - the right of authorship, the right to a name, the right to protection from any distortion and the right to protect the author's reputation - since these rights are protected indefinitely. In the opposite situation, the pressure on the brake pedal is not transmitted to the brake calipers or wheel cylinders.

Contamination of a liquid causes it to become compressible. This results in a soft feeling when applying the brakes, which can eventually lead to complete dysfunction.

Check the elasticity of the brake pedal. If dips are felt when it moves, there is still air in the system and further bleeding is required. If repeated bleeding does not bring satisfactory results, the master cylinder seals may be worn out.

Nitrogen Advantage

Nitrogen is a dry gas. Therefore, tires inflated with nitrogen will not burst at high speeds. Another important factor in favor of nitrogen is the gradual decrease in pressure during puncture.

The pressure drop in rubber with nitrogen is not noticeable, and it does not drop as sharply as in the case of conventional gas. In addition, this gas allows you to feel less road irregularities. Its other best feature is that it does not create condensation. Seeping through the tires, it does not damage the metal of the wheels.

However, there are disadvantages to dry gas. This is a high price. And you can hardly find it at ordinary vehicle service stations. Although it is common among racers.

Re: bleeding brakes on a 2008 Toyota Corolla.

Contamination of a liquid causes it to become compressible. This results in a soft feeling when applying the brakes, which can eventually lead to complete dysfunction. To troubleshoot problems, you will need the help of an assistant, since performing some actions at the same time alone is simply impossible.

Place the car on a level surface, and after turning off the engine, move the gear shift lever to the reverse or first gear position.

Support the wheels and release the handbrake. After removing the master cylinder or if the reservoir was empty, the air must be removed from it.

Air can also enter when the amount of working fluid is below the minimum level. Remove the brake pipes from the master cylinder 5. Smoothly press and hold the brake pedal 6.

For models with ABS system

Plug the cylinder outlet holes with your fingers and release the brake. Repeat the steps once. Bleeding begins with the longest brake line.

An assistant will help bleed traditional brake systems.

It will be impossible for one person to fix malfunctions, since bleeding Toyota Corolla brakes requires a “4-hand game”, with their repetition 4 times (of course, according to the number of wheels).

Algorithm of all necessary actions:

- Bleeding begins with the longest brake system.

- Place the car on a level plateau. Turn off the engine and place the gear lever in the reverse or 1st gear position. Lock the wheels, lower the handbrake.

- Pre-fill with a working mixture similar to SAEJ 1703, VSS116DOT3.

- Remove the master cylinder, be sure to pump out the air from there (if it is empty or the fluid level has reached a minimum).

- Remove the brake pipes from the cylinder.

- Press the brake and hold it smoothly, without jerking.

- Pinch the cylinder outlets with your fingers and release the brake.

- Learn this repair procedure and repeat it 3-4 times.

- Connect the tube to the brake caliper.

- Press and release the brake several times, loosen the bleeder screw and bleed the air. Lower the pedal.

- Repeat the process until the liquid stops flowing out (simultaneously with the appearance of air bubbles in it).

ABS bleeding sequence

- First, we look for and remove the fuse in the fuse block that is responsible for the operation of the anti-lock braking system.

- Next, we jack up and remove one front wheel, and look for the brake wheel cylinder (BWC) fitting.

- After this, we put a hose on the fitting (from the hydraulic level, for example).

- Open the fitting one turn.

- One presses the brakes all the way and holds it in that position.

- Now turn the ignition key to turn on the hydraulic pump (the ABS indicator lights up on the instrument panel).

- The second person watches how air is removed through the hose and, after removing the air, tightens the fitting.

- We release the pedal only after tightening the fitting.

- Now, how do you know that all the air has escaped from the ABS? This shows the ABS icon on the dashboard, if it goes out after removing the air and tightening the fitting, then all the air has escaped.

The correct sequence for bleeding the ABS system

There is a specific order for properly bleeding an ABS system: right front wheel, then rear, then rear right, and then rear left wheel. If during such work the fuel fluid leaks out of the system, it is necessary to fill the system with new fluid. And to do this, you need to know what fluids can be mixed and how much brake fluid is needed for replacement.

Sequence of operation for the front wheels:

- Turn off the ignition (key position “0”).

- Remove the terminals from the brake fluid reservoir.

- Take a bottle with a small amount of brake fluid and a hose. We lower one end of the hose into the liquid, put the second on the fitting and open the fitting with an open-end wrench. It is advisable to use a transparent hose from the hydraulic level so that you can see whether air bubbles are coming out or not.

- Press the brake pedal and hold it in this position.

- The second person (at the wheel) looks to see if the air is coming out, and after the air bubbles have stopped coming out, he closes the fitting with a key.

How to bleed rear wheels with ABS:

The procedure differs for pumping the rear wheels. After the front wheels, the rear right wheel should be pumped in the following sequence:

- We also put the hose into the bottle of liquid and into the caliper fitting.

- Depress the brake pedal all the way.

- Turn the ignition key to position “2”.

- Hold the brake pedal until the hydraulic pump completely expels the air bubbles.

- Close the fitting and release the brake.

For effective bleeding, when working with the brake system of the rear left wheel, the procedure must be adjusted. Namely:

- As in other cases, put on the hose and unscrew the caliper fitting 1 turn. When pumping with the rear left wheel, the brake does not need to be applied immediately.

- Turn the ignition key to start the hydraulic pump.

- After the air comes out, press the brake pedal halfway and close the fitting.

- Next, release the brake and wait for the hydraulic pump to turn off.

- Turn off the ignition.

- We connect the disconnected connector of the TJ tank.

This video shows how to bleed anti-lock brakes on Audi A4, Audi A6, Volkswagen Passat B5 and others.

how to bleed brakes

Folks, tell me how to properly bleed the brakes on a spare tire, friends advise, but for some reason everything is different, as I understand, pumping the brakes on a car with and without ABS is different, the location of the steering wheel and the order in which each wheel is pumped also affects.

There are 20 replies to this topic

It’s like a cross on a cross, but it’s interesting which side to start with. At one service station they said that on wheels the opposite should be done, i.e. on the other hand, which gave rise to a lot of questions

Starts with a long diagonal.

That is, front left - rear right, front right - rear left

Operating procedure

First, the car must be placed on an overpass, jack, lift or inspection hole. Then you open the hood and unscrew the oil reservoir cap. After this, start draining the waste. The drain order is: left rear wheel, right rear, then right front and finally left front wheel.

To drain the oil from the system in one wheel, first remove the plug from the fitting. Then put the hose on it, lower the free end into a container for processing. Unscrew the nut near the fitting; oil should flow out. Drain until it stops leaking. Then - other wheels. Once you have drained everything, close all the nuts.

Then add new brake fluid to the reservoir. You need to pour a little more than half a liter, focus on the divisions in the tank. Sit in the car and press the car brake 10-15 times. After that, crawl back under the car and bleed the oil - unscrew the nut until the oil begins to flow through the hose, then close it. So all the wheels are in the same order in which you drained the oil. After this, put the caps on the fittings, close the tank, hood and drive off the overpass or pit.

Bleeding the car clutch

We bleed the clutch in the same way, press the clutch pedal several times and bleed the old DOT4 brake fluid through the clutch bleeder nipple on the clutch cylinder. At the same time, do not forget to constantly monitor the level of brake fluid in the reservoir so as not to air the system.

Bleeding the clutch on a Toyota Corolla 2005

At the same time I ordered it from existential and installed caps on the bleeder fittings; I had two caps missing. I haven't seen any caps in stores. I ordered a non-original: Metzger air valve bolt article Z 0125 , costing 32 rubles 14 kopecks for two caps. The original Toyota costs 150 rubles each, but it’s not worth it.

Cap (air valve bolt) Metzger article Z 0125