- Automatic transmission automatic transmission repair

- Manual transmission repair

- TOYOTA

- Camry

REPAIR OF TRANSMISSION TOYOTA Camry 7 6 5 4 3 2 1 MECHANICAL GEARBOX TOYOTA Camry installation replacement buy all modifications 1.8 2.0 2.2 2.4 2.5 3.0 3.3 3.5 repair and restoration of shafts argon welding of manual transmission housing Moscow city

Artem 8 965 126 13 83 Vadim 8 925 675 78 75

Complete vehicle diagnostics during repairs – free of charge!

Having a high level of professionalism, extensive experience in repairing manual transmissions, and our own warehouse of spare parts, we carry out diagnostics, sale, replacement and repair of all types of manual transmissions for the TOYOTA Camry car. Box repair begins with an initial, mandatory free diagnosis.

Cost of work for repairing a TOYOTA Camry gearbox:

| car entry diagnostics | for free |

| removal and installation | 5,000 rub. |

| disassembly and assembly | 5,000 rub. |

| Replacing the clutch at the request of the car owner | 2,000 rub. |

| filling the gearbox with transmission oil | for free |

A range of services for repairing a manual transmission of a TOYOTA Camry:

- consultation with a repairman /by phone free of charge/

- delivery of the car for repair /within Moscow RUB 3,000. From the Moscow region and other regions of the Russian Federation - by agreement/

- comprehensive vehicle diagnostics / determination of the presence of a malfunction in the engine, manual transmission, ABS, brake system; checking the vehicle's electrical circuits for corrosion, checking the kinematic damage of the unit, checking the transmission oil level, checking the functionality of the clutch hydraulic system/ - free of charge during repairs

- visual inspection, body integrity check

- checking the transmission oil content for the presence of steel, aluminum or bronze chips

- opening the pallet /if necessary/

- removal from the car

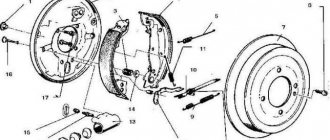

- disassembly, washing of parts and assemblies

- defect detection /presence of the car owner is mandatory/

- agreement with the car owner on the cost of complete repairs and the completion date of the repairs

- receipt from the spare parts/repairs warehouse. kit, consumables, components/

- repair / argon welding / gearbox housing if necessary

- assembly

- clutch replacement /at the request of the car owner/

- car installation

- refilling with transmission oil

- output diagnostics and test drive of the car

Warranty from 3 to 24 months or 60,000 km. mileage

| Phone number of the repairman: | Artem 8 /965/ 126 13 83 Vadim 8 /925/ 675 78 75 |

| Tow truck assistance /24/7/, dispatcher: | 8 /926/ 167 15 40 8 /985/ 888 68 14 |

We have a stock of restored TOYOTA Camry 1.8 2.0 2.2 2.4 2.5 3.0 3.3 3.5 transmissions /see article replacement/. If the car owner wishes, we can replace the faulty one with one taken from the exchange stock, which is often more economically feasible.

Repair stages

Toyota automatic transmission repair sequence:

- evacuation of the car to the Tiptronic car service;

- diagnostics and troubleshooting;

- calculation of repair costs;

- removing the unit from the car;

- restoration of the box, replacement of necessary spare parts;

- assembly and installation of the module;

- testing and calibration.

The cost of the work directly depends on the nature of the breakdown and the complexity of its elimination. The service station master individually calculates the cost after the diagnosis.

Prices for additional work

| № | Job title | Sum |

| 1 | Comprehensive troubleshooting of manual transmission (disassembly - assembly) without repair | 4000 |

| 2 | Change of oil | 2000 |

| 3 | Removal and installation (as a separate job) | 8000 |

| 4 | Replacing the clutch with the box removed | 2000 |

Causes of malfunctions

The most common causes of Toyota automatic transmission malfunctions are:

- breakdown of solenoids;

- contamination of the valve body;

- overheating and slipping of the hub and bushing;

- wear or destruction of the clutch locking lining;

- torque converter failure;

- wear of friction discs;

- failure of the control unit;

- oil leakage from under the sealing rings.

A machine breakdown may occur due to untimely maintenance and oil changes. The accumulation of metal shavings can interfere with the normal operation of the automatic transmission. The mechanics of the Tiptronic car service will repair the Toyota Camry automatic transmission after any breakdown.

Spare parts for manual transmission repair:

- economy - from 3,000 to 8,000 rubles. /use, at the request of the car owner, only used parts to reduce the cost of repairs/

- business - from 8,000 to 28,000 rubles. /replacement of only directly damaged parts in the unit/

- executive - from 28,000 to 60,000 rub. /replacement, regardless of damage, as a set: oil seals, carrier bearings, needle bearings, synchronizers, stoppers, coupling hub locks - plus directly damaged parts/

Our own warehouse of spare parts necessary for the repair of manual transmissions. Bearings, seals, gears, synchronizers, gear couplings, shafts, differentials, manual transmission housings are in stock and on order for all brands of cars.

See the photo report of the Toyota Camry gearbox repair below the text...

Toyota Camry is one of the most popular models of the Japanese concern, having already survived 8 generations. The latest version of the comfortable city sedan was presented in 2021, the car is officially supplied to the Russian market. The model is assembled in many countries, including at the Russian automobile plant in Shushary. The latest model received the latest electronic equipment, including a 360-degree all-round view, the Toyota Touch 2 multimedia system, and tracking systems. The car is equipped with a new 3.5-liter gasoline

, power was specially reduced to 249 hp. for higher sales on the Russian market.

Our advantages

Advantages of the Tiptronic service station:

- We carry out repairs of any complexity in 1-3 days;

- two-year warranty on all types of work;

- We evacuate the car to our station for free and carry out diagnostics;

- all spare parts are in stock;

- We provide consultations by phone.

When carrying out self-diagnosis or repair of the automatic transmission, the likelihood of more serious malfunctions increases. This leads to higher restoration costs. Also, moving a car with a faulty automatic transmission on your own can lead to an emergency.

Use the services of a professional Tiptronic service station. Mechanics will conduct diagnostics, identify all breakdowns and repair the car within 1-3 days after your call.

Features and options of gearboxes

The latest version of the popular sedan is equipped only with an 8-speed automatic transmission

– it provides the smoothest gear shifting. Previous generations were equipped with a 6-speed automatic transmission and a 5-speed manual transmission, and manual transmissions continue to be in high demand in Russia. Although it is less comfortable to use than an automatic, it makes it possible to reduce fuel consumption and accelerate the car to high speeds faster.

The 5-band mechanics are designed for long-term operation: the simple design and high reliability of the components ensure its use for 250-300 thousand kilometers. The unit includes 5 synchronized forward gears and one reverse gear. The mechanics provide the car with completely manual control: the absence of electronic components makes it possible to fully control the car in any driving situation.

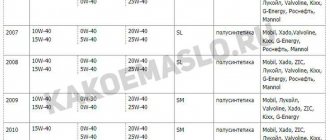

To increase service life, it is important to change the oil

: Transmission fluid is responsible for reducing friction and dissipating excess heat. When it is contaminated with metal shavings, it loses the necessary properties, which leads to rapid wear of parts. In Russian conditions, it is recommended to change the transmission fluid at intervals of 60 thousand kilometers; this will make it possible to significantly extend the life of the gearbox. For replacement, use oil that meets the 75W90 standard; it is advisable to choose original transmission fluid.

Automatic transmission repair Toyota Camry

The family of four-speed automatic transmissions from Aisin Co (U140E, U240 and U241) is the most popular and widely repaired. The U140E was created with the prospect of further expansion to five speeds, and therefore a third additional planetary gear set, Underdrive, was introduced into the design.

The U140E was originally installed in 1998 on the Lexus RX330, with the name from "Aisin Co" AW90-40LS and a 2.4 liter engine. In the same year, many positive reviews were collected, and the next year the U140 (90-40LS) was installed on the Lexus ES300 with a six-cylinder three-liter engine.

In 2000, the U240 modification (91-40LS for Lexus) appeared, and the U140\U240 began to be installed en masse on the most popular Toyota cars intended for the Japanese market (Highlander, Harrier, Caldina, etc.)

The option for all-wheel drive (FullWeelDrive - 4x4) cars has the letter F (for example, U140F). But the market was not interested in three-liter engines in this series, and in 2003 it was replaced by stronger five-speed U250s. With a maximum 2.5-liter engine, the U140 automatic transmission became simply unkillable.

The engines of passenger front-wheel drive cars with lower power received a modification of the U240 automatic transmission. It has been tested on second-row Toyota models (Corona, Caldina, ...) with 2.2-liter engines. Following this, after minor changes, it became the best-selling U241 box, working on popular Toyota cars.

Installed on front-wheel drive and all-wheel drive cars of the middle class, with an engine from 2 to 3 liters, U241E (U240E) have been successfully operating since 2000. They are equipped with the popular Camry, Avensis, RAV4, Celica, Highlander, etc. Compared to the U240E, the U241 has slightly stronger pumps, drums, axles, and planets, which contributes to the confident transmission of more torque.

The design of these automatic gearboxes is so modern and reliable that even in the presence of a weakening third planet, U240-241 automatic transmissions are still installed in Japan on the super popular Corolla, Camry and RAV4.

When the problems of the first U140 releases were successfully resolved, Aisin, based on this design, released in 2001 a more comfortable five-speed automatic transmission series U150-U250.

Typical problems U240\U141

The relatively recently introduced family of these automatic transmissions leads among all Japanese-made automatic transmissions in terms of the number of appearances in repair services. Here the U240-140 is overtaken only by the European ZF 5HP19 and 6HP19-21. AL-4 (DP0) is located somewhere nearby. But these are not reliability indicators, but data on cars that end up in repair due to their age or due to too early repairs.

The very first need for U140 \U241 is to change the oil and universal filter with pan gasket. The first generation filters were produced in 1998-1999, and were metal with a steel mesh. With the release of a new filter in 1999, the pan was modified to accommodate it.

Repair of valve body U140 - RUB 15,000.

Until 2004-2005, Toyota-Lexus cars used T-IV semi-synthetic oil. Gradually, Toyota began to use “non-replaceable” WS synthetic oil, introducing the necessary software changes in electronic control. With the new hydraulic units of 2006, WS synthetics moved into the category of recommendations.

Cork pallet gaskets lead the way in terms of sales.

The filter here is disposable and has a felt double membrane. It fully performs its functions for 150-180,000 km. However, it is recommended to change it every other oil change. An aging transmission reduces this period even further.

From repair kits of gaskets and seals (Overhaul Kit), non-original Overhauls are usually ordered. Transtek is slightly more expensive, while ATOC is cheaper. Or ALTO repair kits, without pistons.

The most disciplined owners order clutches as a whole set, especially in cases where the machine has been overhauled or there is burning in the oil. Clutches soaked in burnt oil slip, dissipate heat poorly and greatly lose their performance, which speeds up the approach of the next overhaul.

Aisin's hardware received good reviews in terms of unpretentiousness and reliability.

Problem areas of automatic transmissions of the U140 and U241E series.

The risk group includes heavy vehicles with three-liter engines, where the hardware is loaded to the limit, and the likelihood of the first major repairs occurs before the required 200,000 km.

The main repaired item in older automatic transmissions, especially for the U140, is the front planetary gear (Output Planet). As a rule, due to extreme loads, the axis of the satellite gears breaks down. The contact patch between the satellite gears and the sun gear is reduced, which accelerates the destruction of the “teeth”.

In many cars with a powerful three-liter engine, it is difficult for the front planetary gear to withstand high torque values, complicated by a lack of oil. Owners of such cars are advised to avoid aggressive acceleration and driving over rough terrain.

The presence of hedgehog shavings on the pan magnets may indicate problems with the front planetary gear 582. After 150,000 km, fractions of metal chips larger than 1 mm appearing in the oil pan may indicate the beginning of gear destruction. A worn-out planetary set renders the pump and other planets unusable. This planetary gearbox must be replaced as soon as possible in order to maintain the functionality of the functional components of this wonderful automatic transmission.

The sun gear is mirrored when paired with the front planet. At the same time, the bearing must be replaced. With further operation of the car with this malfunction, the ring gear will also be broken by metal crumbs.

The next stage of destruction will be the rear planetary gear, broken by fragments of crushed metal from the front planetary gear. At the same time, the shell drum (Output Planet) is replaced. Sometimes this chain of damage involves the hub for the clutches, or the sun gear on the drum. Here, a lot is influenced by where exactly the metal crumbs are carried by the oil.

The back cover, considered the second “weak link” of this design, is a headache for designers - in the U140-240 models it plays the role of a support.

This problem is faced by owners of cars with powerful engines, such as Lexus RX300, RAV-4, Camry. Moreover, for the most part, this applies to cars of recent years, where, according to the latest fashion, the computer allows the driver to increase the transmission load to the maximum limits.

Many cars arrive for service with the back cover broken using a wedging Teflon ring. Loss of oil pressure causes the clutches in the Direct clutch pack to slip and burn. The soft aluminum alloy cover is resistant to extreme lateral loads. This unit has been improved since 1999, and today there are several versions of covers on the market, released in different years.

This problem is characterized by significant bending loads coming from the differential (No. 340720) to the “Direct” drum shaft during aggressive driving, or, in other words, high torques. Additionally, it is provoked by contaminated oil, which wears off the Teflon coating of the o-ring.

This happens when the torque is close to the maximum value. Four, five (U150) and six (U660) speed gearboxes were developed for different driving styles. The “unkillable” four-speed automatic transmission is designed for quiet driving up to 400 - 500,000 km. For fans of fast driving, a six-speed automatic U660 is available.

With an existing three-liter engine, you should change the oil more often, and also repair the torque converter as soon as oil contamination increases. Instead of replacing, you can restore the back cover.

According to statistics, clutches and steel discs in the “Direct” package are replaced 3-4 times more often than in other packages. A typical order consists of Direct clutches and steel discs. Half of the orders also contain the second-largest Forward package, containing clutches with steel discs.

As mentioned above, a common cause of failure is the Teflon compression ring (340179AT), other than the break seat cover (Direct).

This causes the loss of pressure parameters from the package, unsatisfactory pressing of the clutches and, as a result, the “Direct” package burns out completely. If there are signs of irregularities in the operation of the “Direct” package (test table), it is necessary to immediately replace the rings and consumables so as not to replace the entire drum and back cover.

And do not forget that on heavy machines the computer settings allow it to be loaded in excess of the set torque.

A popular replacement in the same "Direct" clutch package is a rubber-coated piston (Direct Clutch) with a holder. Existing rubber rings simply cannot withstand high temperatures, dry running and vibrations.

During long-term operation, accompanied by a lack of oil or a broken planet, the pump bushing often requires replacement.

And if long-term operation of the automatic transmission is accompanied by a leak of the pump seal, then it is necessary to order the entire oil pump.

To overhaul aging automatic machines, a rubber-coated piston (with retainer), Piston U240/ U241 Underdrive Clutch #1 is often required.

A characteristic defect of electronic control units (Engine Control Unit - ECU) of the first years from Fujitsu is the lack of soldering of contacts. As a result, the bags burn and the pressure is not stable. This problem was typical mainly for the first RAV4 releases. The repair process for this unit is not complicated, does not require special material costs, and can correct this factory defect without dismantling the box itself.

Almost every repair trip is accompanied by a preventive replacement of the pump seal. The left axle shaft seal on the housing side, with an outer diameter of 80.26 mm, also needs to be replaced. These left and right axle shaft seals are different for U240 - U140E - U246 - 141F.

In the case when the oil seals on a long-term machine are leaking in the absence of other deviations in the operation of the box, this may be a signal that the time has come for the most affordable planned overhaul. In this case, torque converter consumables and worn automatic transmission consumables are replaced. With this defect, a filter is usually ordered with an “Overhaul Kit”. The valve body and solenoids are cleaned.

Potential electrical problems U140A (H) - U240/1.

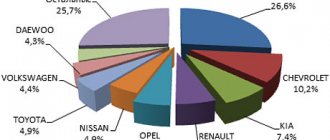

In terms of the number of cars with automatic transmissions in use, Toyota firmly holds first place in Russia. The large number of automatic transmission repairs of this type is not due to the special quality of these boxes. It’s just that this machine is installed on millions of popular and “long-lasting” cars. Drivers, due to many years of impeccable operation, stop monitoring the oil level in the box. And they also test the strength of the three-liter engine, making sure of the trouble-free operation of the Toyota transmission.

Frequent breakdowns were also influenced by the requirements of the modern market, which required machines to jump above their heads. The task was to make the boxes work like “chip” ones, compared to the widely advertised DSGs. Yes, and they switched unnoticed, keeping up with the CVTs and DSG. This unaccountable pursuit of competitors loudly shouting about quick victories led to the fact that automatic transmissions began to work faster, more convenient to switch, but at the same time they worked as “disposable” DSGs and CVTs, sometimes not reaching the required 200,000 km. Repair and maintenance of U140-240 transmissions are so well studied by repairmen, and the cost of spare parts is so low due to competition that knowledgeable owners prefer to repair these automatic transmissions instead of buying a used “pig in a poke” from a used machine.

| Service | Price |

| Electronic diagnostics of automatic transmission. | For free |

| Partial oil change (without removing the pan). | from 1,500 rub. |

| Complete oil change. | from 9,000 rub. |

Removal/Installation:

|

|

| Automatic transmission overhaul. | from 10,000 rub. |

| Automatic transmission adaptation. | from 3000 rub. |

| View the entire price list | |

Possible causes and signs of common problems

Malfunctions of a manual transmission can be associated with factory defects or natural wear and tear of components, but more often they arise due to the fault of the driver. Violation of the recommended maintenance periods, the use of low-quality consumables, an aggressive management style - all this leads to the rapid destruction of parts and various malfunctions. Many of them can be identified at an early stage, this will make it possible to eliminate problems inexpensively

.

Toyota Camry gearbox repair

may be required if the following symptoms of malfunction are detected:

- An extraneous hum, indicating wear of the bearings. They suffer due to high mechanical loads; in some cases, problems with bearings arise after the first 100 thousand kilometers. Damaged parts need urgent replacement.

- Other noises, such as grinding, rustling, or crackling, may indicate a lack of oil and increased friction. Transmission diagnostics and urgent repairs will be required.

- Difficulty shifting the lever or the inability to find one or more gears indicates problems with the shift mechanism. You need to urgently seek help from a specialist auto repair shop.

Our workshop offers qualified repairs on favorable terms. Experienced specialists will conduct free diagnostics and quickly fix all detected problems. Defects of parts are carried out in the presence of the customer.

Signs of breakdown

The most common signs of automatic transmission malfunction on a Camry are:

- inability to switch module operating modes;

- locking the selector in a certain gear;

- the appearance of shocks during movement, which only intensify over time;

- vehicle movement when the lever is in position P;

- noise from the automatic transmission while driving;

- spontaneous switching of speeds;

- There is no downshift when the gas pedal is depressed.

If one or more signs of failure of a vehicle component appear, diagnostics of the Toyota Camry automatic transmission is necessary. Continuing to drive with such a box can lead to damage to the drive or other parts of the car, so it is better to call a tow truck.

Why is it beneficial to contact us?

The specialized workshop offers fast and reliable repairs: a one-year quality guarantee is provided. We will fix problems of any complexity; our specialists work with all representatives of the Toyota model range. We guarantee that all types of faults will be eliminated using reliable spare parts: we have them on sale

A selection of new and

used

To eliminate serious problems, it is proposed to buy a Toyota Camry gearbox

Complete: Choose a new or remanufactured manual transmission to completely replace your worn-out unit. Consult with a specialist to choose the most profitable and reliable repair option.