List of car models in which the engine was installed

- Toyota Belta (08.2008 - 06.2012) restyling, sedan, 1st generation, XP90

- Toyota Belta (11.2005 - 07.2008) sedan, 1st generation, XP90

- Toyota Ractis (12.2007 - 10.2010) restyling, hatchback, 1st generation, P100

- Toyota Ractis (10.2005 - 11.2007) hatchback, 1st generation, P100

- Toyota Vitz (08.2007 - 11.2010) restyling, hatchback, 2nd generation, XP90

- Toyota Vitz (02.2005 - 07.2007) hatchback, 2nd generation, XP90

- Toyota Vitz (12.2001 - 01.2005) restyling, hatchback, 1st generation, XP10

Russia

- Toyota Yaris (09.2009 - 10.2010) restyling, hatchback, 2nd generation, XP90

- Toyota Yaris (10.2005 - 08.2009) hatchback, 2nd generation, XP90

- Toyota Yaris (10.2005 - 08.2009) hatchback, 2nd generation, XP90

Europe

Toyota Yaris (10.2005 - 08.2009) hatchback, 2nd generation, XP90

Instructions for replacing timing belt

The process of replacing the timing chain on a Prado 120 with a diesel engine is labor-intensive and consists of a number of steps. They must be performed consistently and clearly.

The car is prepared for replacement, the battery and protection are disconnected, oil and coolant are drained.

Afterwards, access to the engine is provided so that the timing belt is visible.

The next step is to align the crankshaft pulley according to the dead spots. We must not forget about the belts, viscous coupling, and fan that need to be removed. You will have to remove the cooling radiator, air filters, and intake manifold. Next, you should disconnect the sensors, ignition and injectors from the wiring harnesses to de-energize. They are removed along with the valve covers.

Then you need to remove:

- thermostat;

- pump;

- drive belt rollers;

- pulley;

- power steering pump;

- generator;

- air conditioning compressor;

- bracket with roller;

- camshaft position sensors, VVTI valves.

Unscrew the fastening bolts from the pan and the front cover, after which it is removed to the side.

Then the marks are installed, the main chain, tensioner and damper are removed, as well as the chain from the camshafts. Remaining sealant, O-rings and gaskets must be removed.

Only after these stages the new spare part is installed according to the marks.

Then all the parts are assembled in reverse order.

Step-by-step description of replacement

Dismantling of attachments

In general, replacing the timing chain on the 1ZZ-FE is not much different from other engines.

You should start by removing the decorative plastic cover of the motor. Then:

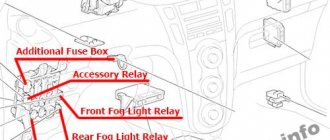

1 — crankshaft, 2 — power steering pump, 3 — tensioner, 4 — coolant pump, 5 — generator, 6 — air conditioning compressor

For the following manipulations it is necessary to jack up the engine:

Marks and removal of the belt tensioner for attachments

Timing marks 1ZZ-FE: the marks on the crankshaft pulley must be aligned with the zero mark on the timing cover. This is done by turning the crankshaft.

Remove the generator belt (there is a protrusion on the belt tensioner that needs to be turned).

To remove the chain tensioner, you need to jack up 1ZZ (under the front part). Do not forget to also remove the pin on which the tensioner was attached so that it does not interfere with removing the timing cover. We also remove the engine mount bracket.

Removing the pump pump, chain tensioner and timing cover

We unscrew the bolts securing the antifreeze pump and dismantle it. After this, you need to lock the crankshaft and remove the pulley. To lock the shaft, put the car in gear (preferably fifth), and insert a screwdriver or wrench between the brake disc and caliper. Then the bolt on the pulley can be unscrewed quite easily.

Then you can begin to remove the timing cover: three 12 bolts and eight 10 bolts, remove the DPKV (crankshaft position sensor) and the power steering pump (power steering).

Afterwards, it is necessary to dismantle the timing chain tensioner.

Removing the old chain

To dismantle the old drive, it is necessary to remove the DPKV rotor, the hydraulic tensioner shoe and a pair of dampers. Align the marks of the crankshaft gear and chain.

Afterwards, you can begin the removal itself: the lower sprocket (moves freely back and forth) is pushed forward, and the chain can be removed. Then we dismantle the VVT-i system gear (by unscrewing the clutch bolt and holding the camshaft) and the exhaust camshaft sprocket.

The new chain, like the old one, will have timing marks; their location on both must match.

All removed elements must be washed and cleaned of traces of sealant, as well as the surfaces of the 1ZZ-FE itself.

List of modifications 2SZ-FE

No modifications were created based on the 2ZS-FE engine; as for its brothers, there were only 2 of them:

- 1ZS FE - a 1.0-liter power unit with a capacity of 69 horsepower, produced 95 H*M of torque and weighed only 69 kilograms, installed on small Toyota cars;

- 3ZS-VE - a 1.5-liter engine, based on a cast-iron cylinder block, developed 107 horsepower and had a short-stroke architecture, installed on low-budget vehicles;

Technical characteristics of 2SZ-FE

| Engine capacity, cc | 1296 |

| Maximum power, hp | 87 |

| Maximum torque, N*m (kg*m) at rpm. | 116 (12) / 4000121 (12) / 4200 |

| Fuel used | Gasoline Regular (AI-92, AI-95) Gasoline AI-95 |

| Fuel consumption, l/100 km | 3.9 — 6 |

| engine's type | 4-cylinder, 16-valve, DOHC |

| Add. engine information | 3 |

| CO2 emissions, g/km | 136 — 141 |

| Cylinder diameter, mm | 72 |

| Number of valves per cylinder | 4 |

| Maximum power, hp (kW) at rpm | 87 (64) / 6000 |

| Mechanism for changing cylinder volume | No |

| Start-stop system | optional |

| Compression ratio | 11 |

| Piston stroke, mm | 79.6 — 80 |

| Engine oil 2SZ FE | 5w-30, 0w-30 |

| Timing mechanism | DOHC, chain drive with VVT-i |

| Engine operating temperature, degrees. | ~95 |

| Engine life, thousand km—according to the plant—in practice | n.d.~200 |

| Environmental standards | Euro 4 |

| Tuning—potential—without loss of resource | 150+n.a. |

| Fuel | 95 |

| How much oil is in the engine | 3.7 |

| Oil change carried out, km | 10000(better 5000) |

| Phase regulator | VVT-i intake |

| Turbocharging | No |

| Hydraulic compensators | No |

| Valve clearances | 0.15-0.25 for intake, 0.25-0.35 for exhaust |

When to change?

Replacing the timing belt on a Toyota Yaris is carried out once every 50-70 thousand kilometers. But in addition to mileage, there are also symptoms that indicate the need to replace this consumable part.

Signs that the timing belt needs to be replaced:

- Visual inspection. If significant sagging of the consumable element between the pulleys is noticed, it must be replaced.

- The service life of the consumable part has expired.

- When purchasing a used car, the part must be replaced.

- Erased notches from the inside of the consumable element.

- Traces of oil or coolant on the timing belt. Replacement must be performed, since it is impossible to remove these liquids from the element material.

There are also indirect symptoms, such as:

- Stopping the internal combustion engine for no apparent reason;

- Exhaust tint changes. As a result, it turns black;

- Metallic knocks, extraneous noises, vibrations during operation of the power unit;

- Reduced engine power.

If at least one of these signs is detected, it is necessary to immediately replace the timing belt. However, before making a replacement, you will need to select a consumable.

Advantages and disadvantages

- The Toyota 2SZ-FE engine is distinguished by the presence of an atypical design, which is more suitable for products. Lined aluminum cylinder blocks have been used since 2000, in most Toyota engine lines. They also have an additional number of fins installed, which are elements of the air cooling system. The advantage of this solution is that the design has become quite simple and cheap to manufacture. The low weight excluded the possibility of repairability of these units;

- the use of a 2SZ-FE cast iron cylinder block allows for a large margin of safety and, therefore, there is the possibility of carrying out full-fledged overhauls. The dissipation of excess heat, due to the high piston stroke length, occurs in the cavity of the massive engine housing. Since the crankshaft axis does not intersect with the cylinder axes, the service life of the pistons and cylinders increases;

- the unsuccessful design of the gas distribution mechanism led to the formation of the main disadvantages of the 2SZ-FE engines. In theory, the presence of a chain drive should provide a high degree of reliability and a long service life, but everything turned out differently. Since the chain drive is long, it is necessary to install two chain guides. Moreover, the quality of the oil fluid greatly affected the operation of the hydraulic tensioner. It is also often possible to replace the shock occurring on the surface of the pistons from the valve plates. This drawback exists because the plate chain weakens and jumps over the pulleys.

The drive of the mounted units is fixed in a non-standard manner. This leads to this. That the 2SZ-FE engine is not similar to other power units, which in turn makes car repair a rather complicated procedure.

Consequences of malfunctions

Problems in the timing chain drive lead to the following problems:

Note. Chain drives of the timing unit can be single- or double-row. The former are not as reliable and durable as the latter, and often break down after a run of 50-80 thousand km. Double-row drives break extremely rarely, even when the owner of the car does not pay due attention to it.

Double-row chains also break, but very rarely

The consequences of these problems may be as follows:

This is what the valves look like after meeting the pistons

A chain that has jumped or broken while driving makes itself felt by a sharp loss of power or complete engine failure. If you were able to hear a metallic knock, indicating the meeting of the piston and valve, then you should prepare for serious repairs to the power unit.

And this is a piston pierced by a valve plate

List of car models in which the engine was installed

- Toyota Belta (08.2008 - 06.2012) restyling, sedan, 1st generation, XP90

- Toyota Belta (11.2005 - 07.2008) sedan, 1st generation, XP90

- Toyota Ractis (12.2007 - 10.2010) restyling, hatchback, 1st generation, P100

- Toyota Ractis (10.2005 - 11.2007) hatchback, 1st generation, P100

- Toyota Vitz (08.2007 - 11.2010) restyling, hatchback, 2nd generation, XP90

- Toyota Vitz (02.2005 - 07.2007) hatchback, 2nd generation, XP90

- Toyota Vitz (12.2001 - 01.2005) restyling, hatchback, 1st generation, XP10

Russia

- Toyota Yaris (09.2009 - 10.2010) restyling, hatchback, 2nd generation, XP90

- Toyota Yaris (10.2005 - 08.2009) hatchback, 2nd generation, XP90

- Toyota Yaris (10.2005 - 08.2009) hatchback, 2nd generation, XP90

Europe

Toyota Yaris (10.2005 - 08.2009) hatchback, 2nd generation, XP90

Description of the 2SZ-FE engine

The 2SZ-FE power unit is designed on the basis of a cast iron block and an aluminum cylinder head. The engine has a long-stroke architecture, the piston stroke is 79.6 mm, and the liner diameter is 72 mm.

Thanks to the 1.3-liter volume and architecture, the engine turned out to be very economical. Naturally, the VVT-i system also affected fuel consumption, because ideally selected valve opening phases allow saving about 10% of fuel, and also improve the power characteristics of the engine. By the way, 2SZ-FE develops from 82 to 88 horsepower, depending on the version of the power unit. The gas distribution mechanism is driven using a plate chain. In the gas distribution mechanism, the VVT-i system plays a special role, which increases the power plant’s requirements for oil quality.

This power unit is used in Toyota small cars such as Vitz, Yaris.

Contract 2SZ-FE

The material from which the cylinder block is made significantly extends the life of the power plant and makes overhaul possible. Thanks to the cast iron block, the engine is not afraid of short-term overheating, and thanks to the long-stroke design, heat removal occurs without any problems. It’s a pity that Toyota engineers did not equip the engine with hydraulic compensators, but they complicated the timing drive by making it a chain drive. The tensioner does not take well to poor-quality lubrication, and at the slightest loosening, the chain instantly jumps and a meeting of valves and pistons occurs, which entails expensive engine repairs.

This power unit forced everyone’s favorite 4e engines out of the market. Yes, in the fight for ecology and fuel consumption, 4e engines looked outdated. They could not boast of low fuel consumption and high environmental class. But these power plants were trouble-free: they did not have such high requirements for quality of service and had a huge resource.

Features of the 2SZ-FE engine:

- the engine is equipped with distributed fuel injection;

- due to the cast iron block, the power plant turned out to be heavy;

- extremely demanding timing chain drive;

- emissions of harmful substances are minimal - from 168 to 190 g/km;

- fuel consumption, according to the manufacturer, is only 6.5 liters in mixed mode;

- coil ignition system;

- long-stroke CPG architecture.

What is the service life of chains according to maintenance regulations and replacement frequency?

On average, a timing chain drive lasts from 200 to 350 thousand kilometers of a car. The indicator varies depending on the driver’s driving style and the quality of the engine oil used to lubricate the links and gears. The operation of the hydraulic tensioner also depends on it.

Reference. In cars from leading German and Japanese manufacturers, a double-row chain often lasts 450-500 thousand km, or even more.

Single row chain drive for Opel vehicles

In contrast to German brands, the two-row drives of Korean small cars from manufacturers KIA and Hyundai work surprisingly little. There have often been cases of stretching and replacing chains with a mileage of 60-90 thousand km on Hyundai Solaris (Hyundai Accent in Ukraine) and KIA Ceed models, which is comparable to the service life of timing belts. Hence the recommendations on when to replace the chain drive:

To avoid troubles associated with timing drive failures, you need to carefully study the car’s operating instructions and the manufacturer’s recommendations for servicing a particular car.

Features 1SZ-FE

The Morse plastic chain is the driving element of the engine. 1SZ-FE is the only unit in which this product is used. (Currently, CVT engines can also incorporate a Morse chain)

Pros of 1SZ-FE

- quiet operation;

- Enormous torque transmission is possible. This is possible because the oil pump and single VVTi are driven by the same circuit. Simply put, the VVTi system regulates the time during which the engine and the consumption camshaft interact. This results in increased vehicle efficiency. Therefore, the torque value reaches a high level. This technology was developed by Toyota automotive engineers in 1996.

Disadvantages of 1SZ-FE

- The long size of the chain led to the need to install additional accelerating blocks and a shoe, which included a hydraulic tensioner. This has led to an increase in oil consumption, and maintenance of the power plant as a whole requires more money.

- There is a possibility of valves bending when the tensioner is loosened or tightened. This may lead to the need to replace the timing chain and carry out major repairs to the power plant.

- The development of the oil pump was carried out without the use of a sump. Therefore, the startup process slows down, since it takes time for the oil to complete a full revolution in the system.

- Despite the fact that the 1SZ-FE is the best engine that Toyota designers have developed, it also has a significant drawback. The valves operate using pushrods, so it is useless to adjust the valves.

Replacing the Toyota Yaris timing chain and belt (Toyota Yaris)

The 1.0-liter Toyota 1SZ-FE engine was produced from 1999 to 2005 in Japan only for the Yaris model family. The engine was equipped with a phase control system of the VVT-i type only at the inlet, and the gas distribution mechanism of the unit was driven using a Morse chain.

The SZ family also includes internal combustion engines: 2SZ‑FE and 3SZ‑VE

Replacing the timing belt on a Toyota Passo with your own hands

Before you start changing consumables, the car owner will need to prepare the necessary tools:

- Set of spanners;

- Ratchet wrench with a set of replaceable heads.

Step-by-step instructions for changing the timing belt:

- The first step is to loosen the generator mount. To do this, we do the following: First of all, remove the right front wheel.

- Then remove the plastic fender liner. It’s worth considering here: it consists of two parts, so first unscrew the top part and then the side.

- Next, take a ratchet and a 14mm socket, and then loosen the generator mount

Next, unscrew the generator tension roller bolt. There is no need to unscrew it completely. 3-4 turns are enough to unscrew it by 2 centimeters. Then we move the roller to the side. Next, use a spanner to loosen the belt tensioner. Then remove the belt itself. Next, we replace the belt, first cleaning the tension roller from possible contamination. Then we reassemble.

It is worth considering that the belt must be installed strictly as in the photo below, otherwise when the engine starts, the tension roller pin may break and the generator pulley guide may break.

1NZ-FE report on timing chain replacement

I read horror stories on the Internet about how people’s hands are torn off, blood flows in a battle with this bolt. My biggest fear was not being able to unscrew it. Therefore, I started not with the pallet, but with the bolt.

Place a driver and a reinforced 17mm socket on the bolt, and place the handle of the key against the drive. We unscrew the spark plugs and unfasten the contacts from the coils to avoid buying new ones.

I didn't give in. Tryn, and it's done Hurray, I thought That's it.

Technical specifications 1KRFE

The 1KRFE was created as an engine for small-displacement urban vehicles. The engine is compact and playful for a mini-car. Has the following advantages:

- high traction at medium and low speeds;

- light weight;

- fuel efficiency;

- low level of emissions of harmful gases. Engines of the 1KRFE series comply with the Euro 4 environmental class.

1KRFE is a three-cylinder direct engine. The cylinder volume is 996 cubic centimeters. More detailed information can be seen in the table below.

| ICE parameter 1KRFE | Meaning |

| Total weight | 69 kg |

| Power | 71 horses |

| Compression ratio | 10,5:1 |

| Cylinder diameter | 71 mm |

| Piston stroke | 84 mm |

| Number of valves per cylinder | 2 |

| Torque | 91 Nm |

| Fuel supply system | EFI – distributed electronic injection |

| Lubrication system | Combined |

| Gasoline consumption in the city per 100 km Gasoline consumption on the highway per 100 km | 5.5 l 4.1 l |

| Fuel octane number | 95 |

| Life resource | 250 thousand km |

The timing belt is created according to the DOHC scheme. All 12 valves are equipped with VVT-i. The intake manifold is made of plastic. This technique made it possible to lower the temperature and increase the filling of the cylinders with the combustible mixture.

Review of faults and methods for repairing them

The weak point of the engine is the timing chain. If the car owner is going to change it, then it is better to change it with all the sprockets. Because they also get very tired. It is best to check the chain size every 80 thousand kilometers. A stretch of 2 mm from the standard size should serve as a signal to replace the timing belt.

Belt tension on 1KRFE

The timing chain is tensioned as follows (follow the symbols in the figure):

- Unscrew the bolt under the letter “A” a little.

- Then loosen nut "B".

- Now you need to tighten the bolt marked “B” until the gap disappears.

- As you turn the “C” bolt, you need to adjust the chain tension.

- Now you need to tighten bolt “B”.

For bolt “A” the tightening force should be 54 Nm, and for bolt “B” - 34 Nm. Carry out the operation with a torque wrench.

It happens that it is not necessary to tension the belt, but to replace it. The process is shown in the next block.

Replacing timing chain 1KRFE

The timing chain is replaced every 100,000 km. Briefly about removing the old and installing a new chain.

- First of all, you will need to drain the oil and antifreeze. Remove the air filter and the engine itself. Remove the coolant pump.

- Remove the ignition coils and cylinder head cover.

- Remove the oil filter and pan.

- Fix the piston of the first cylinder at TDC on the compression stroke.

- Rotate the crankshaft until the marks 0 align with the mark on the timing cover.

- Secure the pulley and the crankshaft itself.

- Remove the timing chain cover.

- Remove the old one and install the new one, having first pressed in the new crankshaft oil seal and lubricated it with oil.

- Align the orange links of the timing chain with the marks on the sprockets. Then the yellow links with a mark on the crankshaft sprocket.

- Install the chain tensioner.

- Install the timing chain cover.

- Install the crankshaft pulley.

- Next, tighten the oil pan with bolts.

- Install the engine.

This is how the timing chain is removed and installed on the 1KRFE engine.

Toyota Vitz 2000 Toyota Vitz SCP10 Replacing the drive belt and spark plugs

In two circles, the marks on the shafts with the marks on the chain will diverge by one link. Forgetting that the marks are not on the block, as usual, but on the chain! Degrease the surface cleaned of sealant with acetone.

We insert the pins into the cover and very carefully wind it up and put the Front cover in place. Well, then everything is in reverse order. After assembly, we smoke for 24 hours and only then start the engine and the sealant dries.

It took 3 hours to disassemble. For troubleshooting and assembly 5. Engine wear has not been detected, everything is in excellent condition. After assembly, all parameters are within acceptable limits.

Of course, it was necessary to change the damper too. Dark gray Camry Grace g 4WD. Use a screwdriver to tear it off the sealant. And we see this: It should look exactly the same after replacing all the spare parts: We remember how everything should be.

We remove the tensioner and immediately the intake shaft rotates a few degrees. And then I ran into problems. They appeared, but not immediately. I installed the chain and aligned the yellow chain links with the marks on the sprockets. I released the rod and got this: Tightened it all down, sealed the washed cap and installed it. And then I saw a star for the position of the shaft cranks in the box with bolts.

Description of the 2SZ-FE engine

The 2SZ-FE power unit is designed on the basis of a cast iron block and an aluminum cylinder head. The engine has a long-stroke architecture, the piston stroke is 79.6 mm, and the liner diameter is 72 mm.

Thanks to the 1.3-liter volume and architecture, the engine turned out to be very economical. Naturally, the VVT-i system also affected fuel consumption, because ideally selected valve opening phases allow saving about 10% of fuel, and also improve the power characteristics of the engine. By the way, 2SZ-FE develops from 82 to 88 horsepower, depending on the version of the power unit. The gas distribution mechanism is driven using a plate chain. In the gas distribution mechanism, the VVT-i system plays a special role, which increases the power plant’s requirements for oil quality.

This power unit is used in Toyota small cars such as Vitz, Yaris.

Contract 2SZ-FE

The material from which the cylinder block is made significantly extends the life of the power plant and makes overhaul possible. Thanks to the cast iron block, the engine is not afraid of short-term overheating, and thanks to the long-stroke design, heat removal occurs without any problems. It’s a pity that Toyota engineers did not equip the engine with hydraulic compensators, but they complicated the timing drive by making it a chain drive. The tensioner does not take well to poor-quality lubrication, and at the slightest loosening, the chain instantly jumps and a meeting of valves and pistons occurs, which entails expensive engine repairs.

This power unit forced everyone’s favorite 4e engines out of the market. Yes, in the fight for ecology and fuel consumption, 4e engines looked outdated. They could not boast of low fuel consumption and high environmental class. But these power plants were trouble-free: they did not have such high requirements for quality of service and had a huge resource.

Features of the 2SZ-FE engine:

- the engine is equipped with distributed fuel injection;

- due to the cast iron block, the power plant turned out to be heavy;

- extremely demanding timing chain drive;

- emissions of harmful substances are minimal - from 168 to 190 g/km;

- fuel consumption, according to the manufacturer, is only 6.5 liters in mixed mode;

- coil ignition system;

- long-stroke CPG architecture.

Disadvantages, breakdowns and problems of Toyota 1SZ-FE

This engine is extremely sensitive to quality and especially to timing of oil changes.

Sometimes the chain jumps and the valves meet the pistons due to the hydraulic tensioner wedge

In severe frost and vice versa in hot weather, air may leak into the intake manifold

Due to the design of the pump, oil spreads throughout the system for a long time after the engine starts.

It is very difficult to adjust the valves, since you need to change the entire drive housing

You can contact the site administrator by email: ru

All texts were written by me, are authored by Google, included in the original Yandex texts and notarized. For any borrowing, we immediately write an official letter on company letterhead in support of search networks, your hosting and domain registrar.

Next we go to court. Don’t try your luck, we have more than thirty successful Internet projects and have already won a dozen lawsuits.

Removing and installing timing chain 1SZ-FE

, 1 — lower engine protection, 2 — pulley, 3 * intermediate roller bracket, 4 — bracket stand, 5 — right engine mount bracket, 6 — engine mount shock absorber, 7 — air conditioning pipe, 8 — hood, 9 — power steering pump , 10 — drive belt for mounted units, 11 — mass air flow sensor connector, 12 — air filter inlet hose, 13 — air filter housing.

Removing and installing timing chain 1SZ-FE

(continuation). 1 - WT system valve, 2 - timing chain cover, 3.14 - gasket, 4 - crankshaft position sensor, 5 - front crankshaft oil seal, 6 - crankshaft pulley, 7 - coolant pump pulley, 8 - wiring harness engine, 9 - ignition coils, 10 - oil dipstick, 11, 12 - positive crankcase ventilation system hose, 13 - cylinder head cover, 15 - oil pan, 16 - timing chain damper, 17 - timing chain damper No. 2, 18 — crankshaft position sensor rotor, 19 — timing chain tensioner guide, 20 — timing chain, 21 — crankshaft sprocket, 22 — WT system sprocket, 23 — camshaft sprocket, 24 — timing chain tensioner, 25 — oil nozzle.

Timing chain 1SZ-FE Removal

1. Drain the engine oil

2. Remove the right front wheel.

3. Remove the lower engine protection.

4. Remove the accessory drive belts

List of car models in which it was installed

This engine can be seen not only on Toyota vehicles. The French also used it to work on cars produced by the Peugeot/Citroen plant.

Here is a list of cars on which the 1KRFE engine can be found:

- Toyota Aygo AB10, Toyota Yaris, Belta XP90, iQGJ10. This engine is still installed on some Toyota cars;

- Daihatsu Sirion M300, Sirion M700, CuoreL275.

Let's move on to French cars:

- Peugeot 107, Peugeot 108 to this day;

- Citroen C1.

The engine has performed well with both automatic and manual transmissions.

Scope of application

Unlike most production Toyota engines, the 2SZ-FE is intended for use in only two families of cars - Toyota Yaris and Toyota Belta. Such a narrow “target audience” significantly increases the price of both the motor itself and spare parts for it. The contract engines available to owners are a lottery, the winnings of which depend more on luck than on other, more predictable qualities.

In 2006, the next model in the series, the 3SZ engine, was released. Almost completely identical to its predecessor, it has a volume increased to 1.5 liters and a power of 141 horsepower.

1KRFE Service Regulations

Maintenance of the 1KRFE is an important element in its care. Routine preventative maintenance is carried out once a year at service centers. Here the chassis and electronic parts of the engine are completely rechecked. If any are worn out or their performance is questionable, then such components are replaced.

Regular oil changes in the 1KRFE engine are also important. The lubricant not only protects engine parts from wearing out, but also prevents the temperature of the unit from increasing during operation.

It is recommended to fill only high-quality motor oils. This

- 0W30;

- 5W30.

If the requirements for lubricant quality regulations are not met, this leads to clogging of the system valves. Frequent use of bad oil affects the entire engine. It will fail before the scheduled time of 200 thousand kilometers.

Replacing antifreeze is as important as changing the oil in a 1KRFE engine. Without it, the system will overheat. High temperatures will increase the timing of valve failure, deform the cylinder head, and dry out the seals so that they begin to leak lubricant. Increased oil consumption will be caused to the engine if the antifreeze is not changed in time and the engine overheats.

The weak link in the entire 1KRFE engine is the timing chain. It is single-row. The lifespan of the chain is 100 thousand kilometers. But experienced mechanics recommend looking under the hood every 50,000 kilometers. Since light cracks or chips in the chain can lead to failure. A belt failure will bend the engine valves.

Often, experienced mechanics in service centers on older 1KRFE engines have to deal with clogged VVT-I valves and clogged throttle valves. Their timely cleaning will give the engine an extra 100,000 kilometers and will not cost the car owner up to 50,000 rubles for major repairs.

How to choose a new set of spare parts

Like other automobile spare parts, timing chains are counterfeited by handicraft and Chinese manufacturers, after which they go on sale. Cunning businessmen are constantly coming up with new ways to deceive customers, for example, placing their low-quality products in original packaging from well-known brands originally from Western Europe. To avoid running into a fake spare part when purchasing a part, follow these recommendations:

The chain is checked for deflection as follows: take it by one end and hold it flat. The second end should sag no more than 10 mm. If possible, check the hardness of the metal by carefully filing it with a file. The steel in high-quality products is hardened, and therefore is characterized by increased hardness and does not lend itself to filing.

Choosing a new belt

The manufacturer recommends installing only original components on a Toyota Yaris/Vitz car. A consumable such as a timing belt is no exception. But if there is no official representative office of the Japanese brand in the place where the car owner lives, you can use high-quality analogues.

Names of manufacturers who produce high-quality timing belts:

- Gates;

- Bosch;

- Contitech;

- Dayco.

Over time, these manufacturers have proven themselves to be reliable. Their components are used in many auto giant factories. After selecting a consumable element, you can begin to replace it yourself.

Assembly

We install the VVT sprocket and exhaust camshaft in place. When tightening the bolts, be sure to hold the camshafts with a wrench.

Replace the crankshaft sprocket and chain guide. On the new chain we find two marks located approximately six links from each other. These are the camshaft marks. We install a new chain, while aligning the camshaft marks and the crankshaft mark.

The chain run from the exhaust camshaft sprocket, through the VVT sprocket and to the crankshaft sprocket must be tensioned. In this case, the marks on the camshaft sprockets must coincide. We install the tensioner shoe. On the block at the top there is a special groove for it, which allows it to “fall out”.

The assembled structure looks like this.

We put the timing cover in place, having previously lubricated the contacting surfaces with sealants. We install a new tensioner. The pin is facing up. Tighten the two nuts.

To bring the tensioner into working condition, you need to: carefully press the tensioner shoe up with a wide screwdriver until it stops, so as not to damage it, and release it. If the tensioner is discharged, then with further pressure the free play will be very small. To be sure, you can bend a small wire hook and carefully move the pin; if it moves, then everything is in order. Well, or use a flexible camera.