I rebuilt the front suspension last summer, but only now got around to the rear suspension. Not to say that she bothered me, it’s just that apparently everything has its time, so I’m ready for it.

The silent blocks were purchased at the beginning of the year; original Toyota and RBI were available (according to some people, also a good manufacturer). Naturally I installed the original, the difference in price is minimal. I paid 2000 rubles/pair for the original.

Although I repair cars for a living, I have never had the opportunity to change silent blocks on Corolla-shaped ones before.

Naturally, before the repair, I scoured the Internet on this topic. Well, I think everything is as usual, in place with a jigsaw, five minutes and done))

The option with a jigsaw is only acceptable if you have completely run out of silent blocks, in my case they turned out to be still suitable and would last for another 3-4 years. Therefore, this method was not successful and only took up time.

I had to open the book.

Naturally, there is no such instrument as the Japanese, so the Soviet one was used.

Using a large puller, using a support washer, I pressed it in, and using a smaller self-made one, I pressed it in. Pressing in turned out to be much faster than pressing in.

The process can be described as follows: jacked it up - removed the wheel - unscrewed the silent block - pressed out the silent block - pressed it in - put it back together. Having experience, everything will take 1-1.5 hours.

Here we can say the entire repair of the rear suspension. Everything else has already changed 1.5 years ago. Cheap, fast and almost simple. This is why I love Corolla))

Along the way, I checked the rear pads. There were no plans to change, I still wanted to travel until spring and buy something more decent. In the end, I still installed what NibK had in stock.

Replacing silent blocks of the rear beam on a Toyota Corolla video

The beam is held on by four bolts: They are screwed on quite tightly, I had to use a jack.

The brake pipe is also secured to the beam with two bolts on both sides. But it will not be possible to remove the tube from the beam without depressurizing it, since it is secured with a continuous ring to the beam.

I made the puller in an hour and a half, and it is also used as a pressing tool. In general, the old silent block is knocked out.

Pay attention to the hole opposite the middle of the silent block in the beam body so that it is blunt. Enough blow.

Spare parts Toyota Corolla Fielder NZE121, 1NZFE

We remove the rear wheels. We remove the rear ABS sensors from the vehicle.

Remove the ABS sensor from the rear axle beam. Unscrew and disconnect the brake pipes.

replacing rear beam silent blocks on a Corolla 121 body (Fielder, Ranx, Allex, Spasio, Corolla)

Unscrew the brake pipe. And remove it from the landing mount.

Let's look at the photos. When all the wires and hoses have been disconnected, we move on to the next stage and begin to free the racks. To do this, take the key we need and unscrew the bolt at the bottom of the rack.

The photo shows the unscrewing process. Next you need to remove the brake drum. To do this, you need to remove four bolts - this will require a 12 mm socket.

Replacing silent blocks on a Toyota Fielder: step-by-step instructions

After all the bolts are unscrewed, you need to remove the drum. Make it very. Next, after removing the drum, we need to pull out the bolt, having first unscrewed the nut and tightened it from the side of the bolt. When assembling, tighten with the machine lowered and loaded last.

After everything is unscrewed, we remove the part from the body fasteners. If it doesn’t come out on its own, you can tap it a little with a hammer.

Step-by-step instructions or how and what to do?

The first step is to lift the car and hang the rear end on wooden blocks. It is important that the car rests on them - this is necessary for the safe carrying out of all further work.

After all this is done, let's unscrew both rear wheels. This is not difficult to do and does not require detailed explanations. After the wheels are removed and we have direct access to the suspension, we first need to disconnect the ABS sensor and unscrew it from the beam. We look at photographs of the work in progress.

Next you need to disconnect the brake pipe. During assembly, it is important to tighten it well, however, you need to do this carefully and not overtighten (the nut is soft).

Next, we unclench the staples and slowly remove the handset. You might want to lay something down as the brake fluid will start leaking. Let's look at the photos.

When all the wires and hoses have been disconnected, we move on to the next stage and begin to free the racks. To do this, take the key we need and unscrew the bolt at the bottom of the rack. The photo shows the unscrewing process.

Next you need to remove the brake drum. To do this, you need to remove four bolts - this will require a 12 mm socket. Let's look at the photos.

After all the bolts are unscrewed, you need to remove the drum. It's very easy to do.

Next, after removing the drum, we need to pull out the bolt, having first unscrewed the nut (you need to tighten it from the side of the bolt. Important!) When assembling, you need to tighten it last with the machine lowered and loaded.

After everything is unscrewed, we remove the part from the body fasteners. If it doesn’t come out on its own, you can tap it a little with a hammer.

Next, remove the rack, having first completely unscrewed the bolts.

The same actions must be performed on the other side. At this point, the parsing procedure is almost complete. If there is nothing else in the way, you can remove the beam from under the car. Let's look at the photos.

That's all for analysis. The photo below shows what a disassembled Toyota Corolla 120 looks like. There’s nothing complicated, everything is as simple as a children’s construction set.

So, the beam has been removed, worn-out silent blocks have been installed in it - they need to be knocked out.

In order to do this, you need to find a suitable tool and a pipe of suitable diameter. Which we will run around, place on the beam and knock out the silent blocks from the beam. It is important to find a suitable support for the removed part before knocking it out. Below are photos and a diagram of how everything should happen. Nothing complicated.

After the old ones are knocked out, we clean the inner surface of the beams, lubricate and install new ones, using approximately the same method, only by tapping lightly with a hammer over the entire surface - you can put a piece of wood between the silent block and the hammer.

This completes the replacement process and you can begin reassembling the car. When assembling, you need to check all the bolts and nuts - tighten them and where necessary, fix them with spindles.

Source: corollafan.ru

Replacing the silent blocks of the rear beam of a Toyota Corolla

In general, the old silent block is knocked out.

Pay attention to the hole opposite the middle of the silent block in the beam body so that it is blunt. Enough blow. When pressed inward, the clip compresses slightly and is very easy, but if you add WD it comes out.

To do this, you need to remove four bolts - this will require a 12 mm socket. After all the bolts are unscrewed, you need to remove the drum. Make it very.

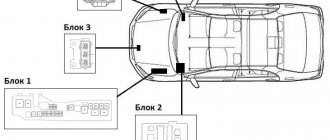

Levers, silent blocks, suspension Toyota Corolla 150

Next, after removing the drum, we need to pull out the bolt, having first unscrewed the nut and tightened it from the side of the bolt. When assembling, tighten with the machine lowered and loaded last. After everything is unscrewed, we remove the part from the body fasteners.

If it doesn’t come out on its own, you can tap it a little with a hammer. Next, remove the rack, having first completely unscrewed the bolts. The same actions must be performed on the other side. At this point, the parsing procedure is almost complete. If there is nothing else in the way, you can remove the beam from under the car.

That's it for the analysis. Although I repair cars for a living, I have never had the opportunity to change silent blocks on Corolla-shaped ones before.

Naturally, before the repair, I scoured the Internet on this topic. Well, I think everything is as usual, in place with a jigsaw, five minutes and you’re done. The option with a jigsaw is only acceptable if you have completely run out of silent blocks, in my case they turned out to be still suitable and would take another year. Therefore, this method was not successful and only took up time.

I had to change the silent blocks of the rear beam of a Toyota Corolla book.

Replacing silent blocks on a Toyota Fielder: step-by-step instructions

Naturally, there is no such instrument as the Japanese, so the Soviet one was used. Full size tube retainer As a result, the brakes remained sealed.

The hubs are screwed on with 4 bolts, it is easier to remove them when the beam is still on the body. Full size And so the beam is removed.

A detailed analysis showed that the silent blocks are still in more or less normal condition:

Replacing silent blocks Toyota Corolla

Parts cannot last forever. This also applies to silent blocks of Toyota cars, which are subject to enormous loads during operation in Russia. If the resource is depleted or broken, it must be replaced.

This article will provide information for replacing silents on cars such as:

- Toyota Corolla,

- Toyota Mark 2,

- Toyota Ipsum,

- Toyota Karina E,

- Toyota Kluger.

REPLACING SILENTS ON A TOYOTA COROLLA

FRONT SUSPENSION

To make it convenient to manipulate the suspension while replacing the silent blocks of the front control arms of the Toyota Corolla 120, you need to put the car in a pit. Thus, there will be no obstacles to access to required places. Next, you need:

- Raise the car using a jack.

- Unscrew the ball from the suspension arm.

- The rear rubber bracket must be removed, followed by the front bolt. The front bolt must be handled carefully as it often breaks.

- If the bolt does break off, then it can be removed using a grinder or other means. It must be cut down and removed, but the threads on the lever must not be damaged. The last resort method is welding the nut.

- Old Toyota bushings are removed by cutting off the protruding part as much as possible and then tapping it. This is necessary to loosen the old oil seal. If this is not done, then even a puller does not guarantee success. This way we remove the back elastic.

- The new rubber band is installed using a press. This tool guarantees the perfect installation of the Toyota silent block in place, without any distortions or play. Before pressing, it is necessary to clean the seats from dirt and corrosion, and also lubricate them. Any lubricant can be used.

- The front rubber bushings are easier to change. They are quite easily pressed out of their installation locations. The latter are cleaned and lubricated. Next, Toyota silent blocks are pressed in again using a press or a special puller. You don't have to do much effort here.

- The levers are now ready to be reinstalled. It is necessary to reassemble in the reverse order, in this case it is necessary to clean the threads of the fastening points from corrosion, if any. WD-40 is suitable for this.

- On the second part of the front suspension of the car, similar procedures are performed to replace silent blocks.

REAR SUSPENSION

These instructions for replacing the silent blocks of the rear beam in a Toyota Corolla 120 will help you correctly carry out all the manipulations yourself and at the same time achieve the quality of the best service station:

- The rear of the car must be hung out. This can be done by installing it in a hole, adjusting wooden chocks, or lifting it with a jack.

- Both rear wheels need to be removed. This is necessary to gain access to Toyota silent blocks.

- The ABS sensor needs to be removed.

- The brake pipe is disconnected and bent. The liquid must not be splashed and poured into a container. It is advisable to lay down a cloth.

- Next, the brake drum is removed. To do this, use a 12mm wrench and unscrew 4 bolts.

- The rack fastenings are unscrewed and the bolts are removed. If the beam and fasteners are difficult to pull out of their places, you can help by tapping them with a hammer.

Work order

Some manuals recommend dismantling the lever and replacing it with a new element. This must be done if, due to significant mechanical impact, the geometry of the lever has changed. In all other cases, installation of new silent blocks is provided.

To do this, place the car on a lift or inspection hole. In this case, the wheels must be removed and the front axle suspended. To install the lever on the right side in the direction of travel of the car, it is necessary to perform some operations.

- Remove the lever from the ball joint; to do this, unscrew 2 nuts and 1 bolt.

- Remove the 2 bolts holding the lever bracket.

- Unscrew the bolt of the front silent block and remove the lever.

Due to the fact that it is screwed into the subframe and access to the threaded connection is difficult, there may be a problem with unscrewing. In order to prevent the bolt from breaking, it is recommended to preheat it.

The procedure for removing the lever from the box side is slightly different. In addition to the above operations, it is necessary to loosen the subframe. To do this, unscrew the cross beam held on by 9 bolts. This will make it possible to remove the bolt, since otherwise it will rest against the gearbox housing.

Replacing the rear silent blocks of a Toyota Corolla is done using a special puller. Replacing the front silent blocks of a Toyota Corolla is carried out using a vice or a hydraulic press. You can’t do without it when installing new parts. It is also necessary to have extensions that match in size with the outer diameter of the rubber-metal parts.

In the absence of special equipment, disassembly can be done independently. And for pressing out and installing new ones, it is better to contact specialists at a service station.

When installing parts, the seats must be cleaned of rust and lubricated with oil. Also remove rust from the bolts and apply graphite lubricant. This will allow you to easily unscrew them the next time you replace them.

Source: rulikoleso.ru

Replacement of rear beam silent blocks. — Toyota Corolla, l., year on DRIVE2

I pressed them out by cutting the clips for about a minute each and they came out easily. I pressed it in with a device consisting of a 12-size bolt, 4 washers of 2 sizes, a nut, wooden blocks for the profile of the silent block, and an angle. I installed all this, placed the blocks on the beam and tightened them with a nut, and on the other hand, I also adjusted the block and corner under the metal profile of the silent block.

Although I repair cars for a living, I have never had the opportunity to change silent blocks on Corolla-shaped ones before. Naturally, before the repair, I scoured the Internet on this topic.

Well, I think everything is as usual, in place with a jigsaw, five minutes and you’re done. The option with a jigsaw is only acceptable if you have completely run out of silent blocks, in my case they turned out to be still suitable and would take another year. Therefore, this method was not successful and only took up time. I had to open the book.

As usual, access to the necessary parts involves lifting the front end and removing the wheel. You can remove both at once if the farm has the required number of jacks.

Replacement of silent blocks of the rear beam of Toyota Corolla 120

You can alternately replace on one side, then on the other. The nuts securing the ball joint are unscrewed and it is removed. The link is removed from the lever.

Next, the front suspension arm itself is dismantled. To do this, all fastening points are removed one by one from nuts and bolts. In the front and in the back. Silent blocks can be changed quite easily using a puller. Don’t forget to clean everything from dirt and corrosion. Parts lubrication is required. Novyo comes into place even with the help of light blows of a sledgehammer.

To install the suspension arms, you first need to bring the rear part together, install the insert and tighten the bolt, and then screw the front part. Then the ball is placed and the link is tightened. The installation of the wheel and the process of replacing silent blocks on the Toyota Karina E is completed. Toyota Kluger and its silent blocks First, we need to say a few words about this model of the Japanese concern. The fact is that the Kluger is a model for the Japanese domestic market and has an export version called Highlander.

Therefore, Kluger is quite rare in our country.

The manufacturer positions the model for lovers of active driving, including on rough terrain. Rear suspension First of all, you need to get a good tool. The ideal option would be to remove the rear beam to make it easier to change daisies. But some car enthusiasts do not want to tinker once again and carry out replacement work on a beam that is not removed from the car. There should not be any problems with replacement; the beam can be easily disassembled.

You should be careful when tightening the daisies - you can hammer them in only as a last resort through a wooden lining. The impacts of replacing rear silent blocks on a Toyota Corolla E120 should be light and soft, and their trajectory will be cross-shaped. So the process of replacing silent blocks on a Toyota Kluger is not much different from similar repairs on other Toyota cars in the rear suspension.

Replacing silent blocks on a Toyota Fielder: step-by-step instructions

If there is a strong play in the place where the beam parts are installed, then this is a sign of a malfunction of the rubber product. Algorithm for replacing the silent blocks of the rear beam on a Corolla body E Let's consider the sequence of actions for changing the silent blocks of the rear beam: Replacing the silent block will require lifting the rear of the vehicle, as well as access to it from below.

Therefore, work must be done in a pit or a lift. You can perform operations on a level surface with the rear of the vehicle raised.

We change the silent blocks of the rear axle beam on a Toyota Corolla E120 with our own hands

Brake unit replacing rear silent blocks on a Toyota Corolla E120 bleeding the system 6. Semi-automatic welding machine or inverter with electrodes Steel angle 1 thickness. Grinder or jigsaw for metal 8. Pliers 9. M12 nuts and washers Gas burner If you still decide to change the silent blocks yourself, then this It’s a long procedure and you can’t do without all of the above. When preparing this photo report, I didn’t take photos of the entire process, because sometimes my hands were dirty, sometimes I just didn’t have time.

Signs of failure of silent blocks

The first sign of failure of the silent blocks of the rear beam of the Toyota Corolla E120 is a knocking sound in the rear suspension.

Diagnostics of these products is carried out on a pit or a lift. In this case, the silent blocks must hold firmly. If there is a strong play in the place where the beam parts are installed, then this is a sign of a malfunction of the rubber product.

We change the silent blocks of the rear axle beam on a Toyota Corolla E120 with our own hands

Almost all owners of the Toyota Corolla E120 were faced with the need to change the silent blocks of the rear beam. This is due to wear of the rubber product, and at the same time metallic ringing and knocking is heard in the suspension.

Video about replacing rear beam silent blocks on a car

The video tells about changing the silent blocks of the rear beam. Will tell you about the process, subtleties and nuances

Signs of failure of silent blocks

The first sign of failure of the silent blocks of the rear beam of the Toyota Corolla E120 is a knocking sound in the rear suspension.

Diagnostics of these products is carried out on a pit or a lift. In this case, the silent blocks must hold firmly. If there is a strong play in the place where the beam parts are installed, then this is a sign of a malfunction of the rubber product.

Algorithm for replacing silent blocks of the rear beam on a Corolla E120 body

Let's consider the sequence of actions for changing the silent blocks of the rear beam:

- Replacing the silent block will require lifting the rear of the vehicle, as well as accessing it from below. Therefore, work must be done in a pit or a lift. You can perform operations on a level surface with the rear of the vehicle raised. But this is not entirely convenient.

- We remove the rear wheels.

- We remove the rear ABS sensors from the vehicle.

Remove the ABS sensor from the rear axle beam.

Unscrew the rack mount from the beam.

A visual illustration of the process of pressing a silent block into a seat.

We press new silent blocks into the rear beam.

Selecting a spare part for the E120 body

For successful and long-term operation of silent blocks, the choice must be taken quite seriously. Thus, the automotive spare parts market offers a wide range of spare parts, not only original, but also analogue ones.

Original

48725-12590 – original catalog number of the silent block of the rear beam of the Toyota Corolla E120. The cost of a spare part is 2000 rubles.

Analogs

Quite a popular analogue.

In addition to the original expensive part, you can purchase an analogue that will not be inferior in quality, but will be much cheaper. Let's consider a list of analogues that can be installed instead of the original.

| Manufacturer's name | Catalog number | Cost in rubles |

| Akitaka | 0101-455 | 1000 |

| Febest | TAB-455 | 1000 |

| Jikiu | BH21267 | 1500 |

| LYNXauto | C9850 | 1200 |

| Masuma | RU-477 | 1500 |

| Nakamoto | R010640 | 1500 |

| Patron | PSE1426 | 1200 |

| Q-fix | Q005-1511 | 900 |

| RBI | T25ZE151E | 900 |

| Stellox | 77-00041-SX | 1600 |

conclusions

Changing the silent blocks of the rear beam of a Toyota Corolla is much more difficult than the front ones, since you have to dismantle the entire beam. The choice of product should be given special attention, since the quality of the spare part will determine the long-term and safe operation.

Part selection

Not original silent blocks.

The choice of silent blocks should be taken seriously, since the quality of the spare parts will determine how stable the suspension will be, as well as the softness of the levers. Many car enthusiasts replace original products with polyurethane analogues, which have a longer service life, but are much more expensive.

Original

48068-12300 – original catalog number of the rear silent block of the front suspension arm. The cost of the product is 3000 rubles.

Analogs

Due to the high cost of silent blocks of levers, many motorists are often looking for a lower quality and cheaper substitute. The automotive market offers a lot of different options.

| Manufacturer's name | Catalog number | Price |

| ABS | 270969 | 1000 |

| Akitaka | 0101-150B | 1000 |

| Amiwa | 02-35-1177 | 600 |

| Caster | FFD9321 | 700 |

| Febest | TAB-ACA30S | 600 |

| Fenox | CAB10013 | 600 |

| Gufu Parts | SRM-21105 | 600 |

| JD | JDT24ZE150B | 1000 |

| Jikiu | BH21118 | 700 |

| LYNXauto | C8572 | 800 |

| Nipparts | N4232056 | 1000 |

| Patron | PSE1428 | 700 |

| Sidem | 845638 | 600 |

| Stellox | 77-00438-SX | 800 |

| VAG | 357 407 182 | 400 |

| VAG | 1J0 407 181 | 1200 |

Replacement of silent blocks of the rear beam of Toyota Corolla 150

I rebuilt the front suspension last summer, but only now got around to the rear suspension. Not to say that she bothered me, it’s just that apparently everything has its time, so I’m ready for it.

The silent blocks were purchased at the beginning of the year; original Toyota and RBI were available (according to some people, also a good manufacturer). Naturally I installed the original, the difference in price is minimal. I paid 2000 rubles/pair for the original.

Although I repair cars for a living, I have never had the opportunity to change silent blocks on Corolla-shaped ones before.

Naturally, before the repair, I scoured the Internet on this topic. Well, I think everything is as usual, in place with a jigsaw, five minutes and done))

The option with a jigsaw is only acceptable if you have completely run out of silent blocks, in my case they turned out to be still suitable and would last for another 3-4 years. Therefore, this method was not successful and only took up time.

I had to open the book.

Naturally, there is no such instrument as the Japanese, so the Soviet one was used.

Using a large puller, using a support washer, I pressed it in, and using a smaller self-made one, I pressed it in. Pressing in turned out to be much faster than pressing in.

The process can be described as follows: jacked it up - removed the wheel - unscrewed the silent block - pressed out the silent block - pressed it in - put it back together. Having experience, everything will take 1-1.5 hours.

Here we can say the entire repair of the rear suspension. Everything else has already changed 1.5 years ago. Cheap, fast and almost simple. This is why I love Corolla))

Along the way, I checked the rear pads. There were no plans to change, I still wanted to travel until spring and buy something more decent. In the end, I still installed what NibK had in stock.

Now all that's left to do soon is to prepare for winter. If anyone remembers, last winter I talked about heating the intake air. In general, the idea is almost realized, so there will be a post about it soon.

When I was processing the bottom and painting the tank, I decided at the same time to change the silent blocks in the rear beam, they were already completely tired, two ribs had burst in one and the rubber bands had peeled off halfway from the clip. There are quite a lot of descriptions of this process, I had already removed the wheels and racks, so I decided to remove the beam to make it more convenient to work. I unscrewed the fastenings of the handbrake cable and the ABS sensor wires (I first sprayed everything with WD 40), and removed the chips from the ABS sensors. Next, I unscrewed the hubs, having previously secured them with wire to the body.

The hubs came off surprisingly easily. I looked on the Internet that if you saw through the clip, the silent block would fly out in a few blows, so I decided to do the same.

As a result, it was not possible to completely saw through it because the clip is not cylindrical in shape, it is thicker in the middle and it is this part that holds it in the beam, and I did not want to saw down the beam itself. I crushed the edges with a chisel inward and slowly knocked them out; they came out very reluctantly. I bought these rubber bands to replace them.

I wanted to buy the original, I found out on Exist that it costs a thousand and a few kopecks (48725-02240), copied the number and went to our dealers, their price turned out to be one and a half times more expensive, now I’m limited in money, I had to buy an analogue. For some reason there was no RBI, I took this (860 rubles per piece), the computer showed the manufacturer was Japan, the packaging said Thailand. The text on the packaging is even and without errors, although this is pleasing. At first I tried to press it in with a bolt and washers, inserting it in the middle (I also saw it somewhere on the Internet), but it didn’t work, don’t waste your time and nerves. I bought this puller for 380 rubles.

I made these frames from the washers that I bought and simply sawed them with a grinder.

The outer diameter of the washers is 70 (I measured 72 with a caliper). I wanted to put 2 so that they wouldn’t get crushed, but one is enough. We set up the puller like this.

There is a thick plate on the back side; I glued it with masking tape (I had it on hand) to make it easier to install the puller. Then he pulled it with a puller and tapped with a hammer (not too hard) on the washer and the puller’s paws, the silent block settled into the beam (tightened, tapped, pulled, tapped...). Thanks to the washer, the edges of the clip were not damaged.

Almost all owners of the Toyota Corolla E120 were faced with the need to change the silent blocks of the rear beam. This is due to wear of the rubber product, and at the same time metallic ringing and knocking is heard in the suspension.

Video about replacing rear beam silent blocks on a car

The video tells about changing the silent blocks of the rear beam. Will tell you about the process, subtleties and nuances

Signs of failure of silent blocks

The first sign of failure of the silent blocks of the rear beam of the Toyota Corolla E120 is a knocking sound in the rear suspension.

Diagnostics of these products is carried out on a pit or a lift. In this case, the silent blocks must hold firmly. If there is a strong play in the place where the beam parts are installed, then this is a sign of a malfunction of the rubber product.

Algorithm for replacing silent blocks of the rear beam on a Corolla E120 body

Let's consider the sequence of actions for changing the silent blocks of the rear beam:

- Replacing the silent block will require lifting the rear of the vehicle, as well as accessing it from below. Therefore, work must be done in a pit or a lift. You can perform operations on a level surface with the rear of the vehicle raised. But this is not entirely convenient.

- We remove the rear wheels.

- We remove the rear ABS sensors from the vehicle.

Remove the ABS sensor from the rear axle beam.

Unscrew the rack mount from the beam.

A visual illustration of the process of pressing a silent block into a seat.

We press new silent blocks into the rear beam.

Selecting a spare part for the E120 body

For successful and long-term operation of silent blocks, the choice must be taken quite seriously. Thus, the automotive spare parts market offers a wide range of spare parts, not only original, but also analogue ones.

Original

48725-12590 – original catalog number of the silent block of the rear beam of the Toyota Corolla E120. The cost of a spare part is 2000 rubles.

Analogs

Quite a popular analogue.

In addition to the original expensive part, you can purchase an analogue that will not be inferior in quality, but will be much cheaper. Let's consider a list of analogues that can be installed instead of the original.

| Manufacturer's name | Catalog number | Cost in rubles |

| Akitaka | 0101-455 | 1000 |

| Febest | TAB-455 | 1000 |

| Jikiu | BH21267 | 1500 |

| LYNXauto | C9850 | 1200 |

| Masuma | RU-477 | 1500 |

| Nakamoto | R010640 | 1500 |

| Patron | PSE1426 | 1200 |

| Q-fix | Q005-1511 | 900 |

| RBI | T25ZE151E | 900 |

| Stellox | 77-00041-SX | 1600 |

conclusions

Changing the silent blocks of the rear beam of a Toyota Corolla is much more difficult than the front ones, since you have to dismantle the entire beam. The choice of product should be given special attention, since the quality of the spare part will determine the long-term and safe operation.

Signs of failure of silent blocks

The first sign of failure of the silent blocks of the rear beam of the Toyota Corolla E120 is a knocking sound in the rear suspension.

Diagnostics of these products is carried out on a pit or a lift. In this case, the silent blocks must hold firmly. If there is a strong play in the place where the beam parts are installed, then this is a sign of a malfunction of the rubber product.

Technical characteristics of Toyota Aqua G - Toyota Aqua, l., year on DRIVE2

Replacing the silent block will require lifting the rear of the vehicle, as well as accessing it from below. Therefore, work must be done in a pit or a lift.

You can perform operations on a level surface with the rear of the vehicle raised. But this is not entirely convenient. We remove the rear wheels.

We remove the rear ABS sensors from the vehicle. Remove the ABS sensor from the rear axle beam. Unscrew and disconnect the brake pipes.

We go into the salon and take off the trim under the rear seat near the floor, see the white plastic clip on the left and right, and disconnect the ABS sensor wiring. We take out the ABS sensor wire from the body, you need to push the rubber plug out near the connector and pull the wire out onto the street, we do this on each side.

We unscrew the ABS wire holders along the beam with the head by 10, do it on each side. The first holder is located on the silent block of the Toyota Corolla rear beam, the remaining 2 pieces are on the side of the beam.

We unscrew the handbrake cable from the hub, M10 bolts 8. Remove the handbrake rubber from the beam and insert the handbrake cable there, at this point you can add silicone grease to the cable itself so that the cable works better 9.

Replacing beam silent blocks [PHOTO REPORT]

Unscrew the Panhard rod from the beam. Unscrew the bolt securing the rear strut to the beam. You can evaluate the condition of the rack silent block. Here we take a small vice, clamp the nut and rip it off, the main thing is to rip it off, and then unscrew it with a wrench.

We take a piece of silicone hose from the VAZ washer, cm enough, screw it in on one side, and put it on the metal pipe of the brake line with the other side so that the brake fluid does not leak out. After all the above manipulations, the beam will fall down; you need to put something under it.

The most difficult thing without a pit is to take a wrench, a 14 or 17 socket and unscrew the bolt securing the beam to the body. The beam is removed, sweat is pouring in. We drink a mug of tea, take a photo of how the silent blocks stand in the beam, but it’s better to take a book and see at what approximate angle the silent block protrusion is relative to the beam. I scraped on the beam as the silent block stood, but still put it a little askew, within the limits of the permitted After these manipulations, it is better to take the beam to a service center and press it in, but if for some reason you do not want or do not have the ability to carry it there, then below I will describe how to change the silent block.

Replacing silent blocks on a Toyota Fielder: step-by-step instructions

We burn out the old replacement silent blocks of the Toyota Corolla rear beam. After the wheels are removed and we have direct access to the suspension, we first need to disconnect the ABS sensor and unscrew it from the beam. We look at photographs of the work in progress. Next you need to disconnect the brake pipe. During assembly, it is important to tighten it well, however, you need to do this carefully and do not overtighten the nut.

We change the silent blocks of the rear axle beam on a Toyota Corolla E120 with our own hands

Next, we unclench the staples and slowly remove the handset. You might want to lay something down as the brake fluid will start leaking.

Let's look at the photos. When all the wires and hoses have been disconnected, we move on to the next stage and begin to free the racks. To do this, take the key we need and unscrew the bolt at the bottom of the rack. The photo shows the unscrewing process. Next, you need to remove the brake replacement silent blocks of the rear beam of the Toyota Corolla. To do this, you need to remove four bolts - this will require a 12 mm socket.

After all the bolts are unscrewed, you need to remove the drum.

Make it very. Next, after removing the drum, we need to pull out the bolt, having first unscrewed the nut and tightened it from the side of the bolt.

When assembling, tighten with the machine lowered and loaded last.

Set of tools for dismantling silent blocks of Toyota Altis subframe

Toyota Altis, also known as Corolla, differs only in its external design and some interior. The car began production in 2000 and was intended for the Southeast Asian market, which is why the manufacturer changed its name to Toyota Corolla Altis.

The interior has changed very slightly, the body has changed at the front thanks to a massive hood and has become longer than the regular Corolla.

The line of power units expanded for the eastern market - 1.4, 1.8, 2.0 were installed.

The suspension of this car may seem stiff, but it is actually very ergonomic. With proper care, all load-bearing elements will last more than 100 thousand kilometers. For example, the ball joints of this car can easily run 150 thousand kilometers with an adequate driving style. Regular car maintenance can significantly extend the life of the car's chassis and save you money on expensive repairs.

The silent blocks of the levers and subframe are the first to fail from the suspension. Since the design is simple, and if you have a special tool for dismantling silent blocks, such as JTC-4164, you can easily change them without the help of a car service. Next we will tell you how easy it is to do this.

Complete set JTC-4164.

Also, to dismantle the silent blocks we will need a sledgehammer (for example JTC-3410).

Procedure.

Dismantling:

- We rest mandrel No. 1 against the silent block. Dismantling the silent block Find out the price of JTC-4164

- We use a sledgehammer to knock out the silent block.

Installation

- We rest mandrel No. 3 against the silent block.

- We thread the power screw from the reverse side.

- We insert mandrel No. 4 and tighten it with a nut.

- We tighten the assembled structure with 17 keys (JTC-3212). Thereby pressing in the silent blocks. Installation of silent block Find out price JTC-4164

Please note that all work can be performed directly on the car.

Product in article

Dismantling:

- We rest mandrel No. 1 against the silent block. !#img56

- We use a sledgehammer to knock out the silent block.