The CVT on the Toyota Corolla, according to reviews from owners, is a reliable unit only if the operating rules are followed. The transmission simplifies the process of driving a car and does not require manual gear shifting. By smoothly adjusting the gear ratio, fuel consumption is reduced regardless of the driving mode.

The Toyota Corolla CVT is a reliable unit.

The concept of a variator

The variator allows you to smoothly change the gear ratio, acceleration and deceleration occur without jerking. The design does not have a pedal-driven clutch; a hydraulic transformer is used to open the engine crankshaft and the primary axis of the box.

The Toyota Corolla uses units manufactured by Aisin, the model depends on the year of manufacture of the car.

Design and principle of operation

The design of the unit includes 2 conical surfaces located on the drive and driven shafts. Torque is transmitted by a metal plate belt, which is constantly lubricated with special oil. The electronic control unit automatically adjusts the position of the belt on the cones, smoothly changing the gear ratio. Wear products entering the oil are captured by a filter and a magnetic plug in the gearbox housing.

Childhood diseases

Toyota Direct Shift-CVT transmission was developed jointly with Aisin AW Co., Ltd. It is produced by Toyota itself. In Russia it can be seen on the new Lexus UX 200 crossover.

And in the United States, the 2019 model year Toyota Corolla Hatchback went on sale in the fall, which is equipped with this CVT. The Corolla sedan, which will appear on the Chinese market this year, will also receive it.

Last December, it became known that all Corolla Hatchbacks sold in the United States were being recalled. It turned out that their torque converter could suddenly fail, immobilizing the car. Dealers should contact owners to replace the transmission. According to American media reports, CVTs are still in short supply, so dealers are in no hurry to notify owners.

But you can be sure that when the new Corolla with Direct Shift-CVT reaches Europe and Russia, it will already be free from “childhood diseases”.

Toyota has already announced the start of deliveries of the new Corolla to Russia, but so far only with a 1.6 l/122 hp engine. and the previous generation Multidrive CVT. 6 Feb. 2021

Main types of CVT

CVTs used on cars are divided into types depending on the method of torque transmission:

- steel belt with a wedge-shaped profile or chain;

- rollers (adjustment of the gear ratio is achieved by changing the angle of installation of the disks).

Clinomeric

The classic variator provides for the transmission of torque due to the friction force between the belt and conical surfaces. The design can be equipped with a planetary gear, which prevents the belt from reaching the end edges of the cones. The unit is compact in size and light in weight; manual shifting of fixed gears is possible.

The clinometer variator has compact dimensions.

Toroidal

The design has a driving and driven disks, between which there are rollers with the ability to change the axis angle.

Depending on the position, the gear ratio changes. Toyota cars do not use a toroidal variator.

Reliability of CVTs used in Toyota Corolla cars

Corollas equipped with a CVT appeared back in 2006. The reliability of boxes of this type in models up to the 11th generation is not high and has caused complaints from owners. This was due to the following reasons:

- CVTs worked mainly due to friction, which caused intense wear on the belt and the working surfaces of the box itself.

- The correct operation of this gearbox depends on the readings of a large number of electronic devices; failure of one of them can cause the variator to malfunction.

Based on this, we can conclude that Toyota Corolla cars produced before 2013 have an automatic transmission that is more reliable than a continuously variable transmission.

In the 11th generation Corolla, after long and painstaking work, these shortcomings of CVTs were eliminated, so new models with automatic transmission are not produced. The new CVT Mulridrive S continuously variable transmission allows you to feel safe and confident behind the wheel, as well as significantly save on fuel consumption.

Advantages and disadvantages

Advantages of the variator noted by owners:

- smooth change in torque;

- reduced fuel consumption due to the optimal ratio of load and crankshaft speed;

- ease of driving.

Disadvantages indicated in reviews:

- the need for regular maintenance with replacement of fluid and filters;

- belt life does not exceed 150 thousand km;

- labor-intensive and expensive repairs;

- in case of breakdown, the car is immobilized;

- The unit is not designed to work with a trailer and quickly breaks down when slipping in snow or mud.

Toyota Corolla 2014: real reviews, comparison with other models

If you compare the Corolla with its direct competitor, the Volkswagen Jetta, you can see the difference in the gearbox. The German car is equipped with a DSG gearbox, to which not every driver quickly adapts.

Car owner review of the 2014 Toyota Corolla

Some reviews of the variator on the 2014 Corolla talk about temporary braking in the car’s operation: if the driver presses the gas pedal hard, the Corolla will not start moving immediately. In city traffic conditions, such problems do not appear: the transmission behaves smoothly, switching is carried out without jerking.

Reviews of the 2014 Toyota Corolla with CVT

This compares favorably with the Japanese DSG, which became famous for its small but unpleasant jolts in traffic jams. Another disadvantage of the German automatic transmission is unreliability: the forums are filled with indignation from dissatisfied owners of broken cars.

Review of the 2014 Toyota Corolla

As for the rest of the technical component and reliability, reviews of the 2014 Toyota Corolla with a CVT are positive.

What automatic transmission is Toyota Corolla e180?

Over the entire production period, the Corolla E180 was equipped with two engines, which came with a CVT transmission - these are 1.6 and 1.8 liter power plants. Since 2014, they decided to change the technology, and now the manufacturer installs the K311 modification variator on its cars.

CVT device - perfect or not

The variator on the Toyota Corolla has a classic design - V-belt. It consists of two pulleys connected by a belt made of high-strength alloy. Torque adjustment is carried out by changing the ratio of the diameters of the driven and driven wheels of the transmission.

Thanks to numerous studies and experiments carried out by Japanese engineers, it was possible to get rid of a problem that was characteristic of almost all variators of that time - rapid wear of pulley bearings. Because of this, there was an extraneous hum in the transmission while driving.

The variator on the 2014 Toyota Corolla avoided this problem: the bearings in it are designed for a longer service life.

Now there are practically no car enthusiasts left who complain about the 2014 model with a CVT. Initially, dissatisfaction was caused by the very presence of this mechanism in the car, and drivers, considering it a complex device, often refused to purchase a car of this configuration. But time has shown the effectiveness of the innovation: engineers seem to have introduced “virtual” gears into the car that can be switched in automatic and manual mode - this turned out to be very convenient.

Operating principle of a V-belt variator

Many were surprised by the absence of the traditional gear shift moment: the usual wait was prolonged, while the car smoothly picked up speed.

What doesn't the variator like?

A CVT can serve the driver for many thousands of kilometers, provided that it is used correctly.

Reviews show that the design cannot withstand overheating, so you should avoid slipping on slippery surfaces and in mud, especially in winter. Otherwise, the gearbox elements overheat and quickly fail.

It is not recommended to tow vehicles or attach a trailer. This leads to accelerated wear of parts and electronic failures. The variator is not designed for additional loads.

The same goes for long trips on the highway. Periodically, the system needs rest to avoid overheating. Fortunately, there is a special indicator on the dashboard that will notify you when it is necessary to cool the transmission. A pause of 10-15 minutes - and you can continue moving.

Toyota Corolla 2014 dashboard

Regardless of the ambient temperature, the Corolla with a CVT needs to be warmed up. Even in winter, 7 minutes will be enough for the transmission oil to warm up to operating temperature.

Is the CVT reliable in Toyota Corolla?

The reliability of the Japanese company's CVTs, which were installed on the Toyota Corolla, is at a high level.

With proper operation, the first major repair may be required after 300-400 thousand km. In order for the gearbox to last a long time, you need to protect it from overheating.

A common reason for drivers to visit a service station is to flush the heat exchanger. If the car is new and has hardly been used, then this problem will not affect it for the next 3-4 years. Subsequent repairs of the heat exchanger are recommended to be carried out at every oil and filter change.

How to drive a Toyota Corolla CVT: reviews

On the forums you can find many tips that will help extend the life of the transmission:

- Do not accelerate sharply after the car has warmed up. The unit may not be able to withstand such a load at the beginning of movement.

- Having gained speed, you need to keep the engine speed in the same range; you should not drive at too high crankshaft speeds, because this is a large load on the box.

- Manual gear shifting should be handled with care. You cannot jump from a very high gear to a very low one and vice versa. Replacing a CVT can be a serious financial shock for the driver.

- Changing the transmission oil in the variator (CVT) in a timely manner will only benefit the car, as will the use of original spare parts purchased from official suppliers.

Changing the oil in the variator (CVT)

Slava: “I bought the car immediately after its release in 2014. The variator scared me. This was something new for me. I had a hard time understanding its structure. I realized that if you drive it smoothly, without sudden starts and braking, the service life of the transmission will increase significantly. And so it happened, I drove 250,000 km, and it’s still a long way from capital. Proper care is the key to long service life.”

How long does the CVT drive on a Toyota Corolla?

The service life of the variator varies. It all depends on your driving style and how well and timely the repair work is carried out.

The officially declared service life of the CVT is about 200,000 km. But if a driver likes sudden starts and neglects to change transmission oil, filters and magnets, then his car’s gearbox may fail before even 100,000 km.

With careful and proper operation, thanks to its high reliability, the Toyota Corolla CVT can last up to 300,000 km without even reminding itself.

If we compare the gearbox with modern automatic transmissions, we can say: Japanese engineers managed to install a reliable unit on their car.

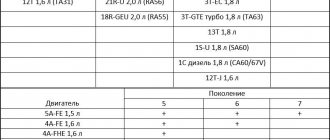

Toyota models with continuously variable transmission

The Toyota concern began using CVTs in 2000 on Opa cars, which were supplied to the Japanese domestic market. In Europe and North America, cars with CVT appeared only in 2009. The first were Avensis and Verso, equipped with a unified K311 unit with different control units. A year later, the experiment was extended to RAV4 crossovers with front-wheel drive or all-wheel drive. Toyota Corolla began to be equipped with a CVT only in 2013. The type of transmission can be determined by the text on the identification sticker, which contains information about the transmission model.

Since 2000, Toyota models have been produced with a continuously variable transmission.

Rules for using continuously variable transmissions of Toyota Corolla cars

For greater reliability of the variator operation, you should follow the basic rules of their operation:

- When used in winter, you should not put heavy loads on the variator, especially if it has not had time to warm up. Optimal temperature conditions will significantly extend its service life.

- The condition and level of the fluid in this type of box should be given special attention, it should be changed and topped up on time.

- Since this type of transmission is not suitable for racing, it should not be overloaded.

- Inspect the sensors in a timely manner, checking their integrity and performance.

- If you find any problems with the variator, do not try to fix them yourself; it is better to contact a specialized service station.

Features of operation and maintenance

During operation, it is necessary to monitor the level and condition of the working fluid. Steel chips in the oil will accelerate wear on the cones and metal belt. Prolonged movement at maximum speed, which leads to overheating of the transmission, is not allowed. The driver needs to smoothly pick up and slow down, avoiding slipping. Before starting to drive, the variator should be warmed up with the car standing and the engine running at idle speed. Do not tow trailers or other vehicles to a CVT-equipped Corolla.

The variator is serviced with fresh fluid refilled after 70-80 thousand km of travel. Some owners try to carry out the procedure 2 times more often, ensuring timely removal of wear products. When servicing, it is necessary to install a new filter (original parts are not supplied for all types of gearboxes), a pan gasket and a drain plug ring.

When draining the crankcase, no more than 80% of the liquid leaves, so you will have to fill and pump out the oil at least 2-3 times in a row.

Frequent malfunctions and repairs

When the working surfaces wear out, the friction coefficient decreases, the car accelerates jerkily, and when the speed is reduced, the engine may stall. In this case, it is necessary to assess the condition of the working fluid. Blackening of the oil and metal inclusions indicate damage to parts. To restore functionality, you will have to disassemble the unit.

Adding fresh fluid can delay repairs for several weeks or months. The burning smell emanating from the oil indicates the need to stop using the variator, which is in disrepair.

The most loaded parts are the rotor bearings. When damaged, a hum occurs, the tonality depends on the speed of movement. Some owners encounter this after 50-60 thousand kilometers. The problem occurs due to metal shavings getting under the rolling elements or due to unstable quality of components at the factory. Fans of sharp acceleration complain that scuff marks form on the cones. In this case, the functionality of the box can only be restored by installing new parts.

Less is lighter and better

The additional stage solved several problems at once. Starting and accelerating put a lot of stress on the engine and transmission. The efficiency of gearing is higher than that of a variator, and the “starting gear” reduces losses precisely at increased loads.

Since the gear pair made it possible to expand the range of gear ratios (even if only by adding one point to it), it became possible to somewhat reduce the range of changes in the gear ratios of the variator. If in the previous model the range was 6.5, then in the Direct Shift-CVT the total range is 7.5, and the variator range is 5.0. Thanks to this, it became possible to reduce the size of the variator parts, and therefore their weight, and with it losses from inertia. Toyota writes that the decline has reached 40 percent.

To speed up the change in gear ratios, the angle between the pulleys has been reduced from 11 degrees to 9. As a result, each bringing the pulleys closer or apart leads to a faster change in the movement of the belt. The speed of change of gear ratios increased by 20 percent.

The transmission is also helped by a new, more efficient pump.

The result of reduced waste and more efficient operation, according to Toyota, was a six percent reduction in fuel consumption.

Is the CVT reliable on Toyota Corolla?

The reliability of the variator directly depends on the management style and the frequency of maintenance. There have been cases where the box has withstood a mileage of more than 200 thousand km without replacing parts. When purchasing a new car, the transmission is covered by a manufacturer's warranty, which is obliged to correct all damage caused by defective parts. When choosing a used Corolla with a CVT, you should diagnose the transmission and evaluate the condition of the unit. On the spare parts market there are units removed from broken cars, so there will be no problems with repairs.

Owner reviews

Owners of Toyota Corolla with a CVT leave different reviews about the service life and characteristics of the transmission. The opinion is influenced by the mode of operation, total mileage and frequency of maintenance of the box. If the owner likes sharp acceleration and driving at high speed, then the CVT will fail after 20-30 thousand km. Calm drivers can use their car for years without complaining about CVT breakdowns.

Positive

Oleg, 28 years old, Tver

I drive a Corolla with a 1.6-liter engine, released in 2021. The car has covered 82 thousand km, 70% of the mileage was on the highway. Speed up to 140 km/h, I rarely use sport mode. There were no jerks during operation; the control unit firmware was factory installed.

Nikolay, 55 years old, Omsk

I am the owner of a Corolla with a CVT and a 1.8 liter engine. I changed the oil in the gearbox for the first time when the mileage was 110 thousand km, the service was carried out at the dealer at a special stand. The drained liquid was clear and did not contain chips. I drive calmly, the speed on the highway is about 100-110 km/h. I warm up the box for 1-2 minutes in summer and 5-7 minutes in cold weather.

Negative

Mikhail, 31 years old, St. Petersburg

I bought a car with a 1.6-liter engine in 2015. At 50 thousand km, a whistling sound from the variator appeared; when switching modes, the tone of the noise changed. The dealer ran diagnostics and found no faults. I sold the car with 80 thousand km mileage, informing the buyer about the potential problem.

The main differences between CVTs and automatic transmissions

Vehicles equipped with both a CVT and an automatic transmission have 2 pedals, which greatly simplifies the driving process and allows the driver not to be distracted. The continuously variable transmission is controlled by a computer; after analyzing driving conditions, it selects the most appropriate gear ratio. Thanks to this, the engine operates in a gentle mode, smoothly and without jerking. Also, thanks to the optimization of engine operation, in the presence of a variator there is no sound characteristic of accelerating.

Both boxes are expensive to repair. Moreover, if the variator breaks down, you must contact only official dealers, due to the lack of knowledge of this type of transmission. Repairing a machine is easier, but it will require large financial investments.

Both boxes require regular oil changes. Transmission lubricant for a variator is expensive, but less of it is required, and the replacement itself needs to be done less frequently. You can change the oil in an automatic transmission yourself; there is a huge range of lubricants for automatic transmissions on sale, but you need to change it more often and the required volume of oil is much larger.

Cars with a CVT and an automatic transmission require a special mode when towing and have a number of restrictions for this.