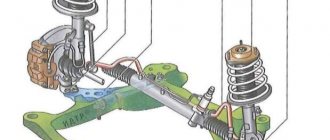

I decided to check the rear suspension, mileage 134,000: — Silents in the trailing arms and axle needed to be replaced. — Silents in the transverse arms are in excellent condition. — I changed the stabilizer bushings earlier and installed the original ones.

I looked at the catalog - there are no separate Toyota bushings, and there aren’t any on the trunnion at all) I didn’t want to install all sorts of “German Febest” and other crap, and I didn’t want to buy levers and a trunnion, and in addition Google

didn't ban me))

As a result of searching, I found out the following.

There is such a car for Americans TOYOTA AVALON (MCX10)1MZFE 04.2000 - 06.2005

- here’s something that suits us from her.

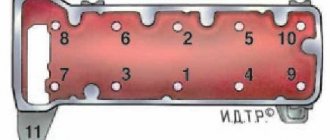

Toyota license plates. 48725-32150

(No. 1 - 4) - into the transverse rods. (

I didn’t change it, so I can’t guarantee 100%

)

48725-03010

(No. 5) - into the axle where the longitudinal rod is attached.

48725-33020-83

(No. 6) - into the trailing arm at the point of attachment to the body.

To replace, you also need bolts and nuts, since in almost all of them they stick and need to be cut off. I got stuck in the trunnion. Therefore, I advise you to immediately buy new bolts and nuts, so as not to run around later, they are the same for fastening to the body and the axle.

Bought: 48725-03010

— 2 pieces (silent in the axle)

48725-33020-83

— 2 pieces (silent in the trailing arm)

9011912131

— 4 pieces (bolts)

9017912091

— 4 pieces (nuts)

When replacing, I only removed the wheel and did not unscrew anything else. Dismantling old silents...

— Disconnected the lever from the body — Cut off the bolts securing the lever to the trunnion — Shredded the rubber silent in the lever, cut the clip with a metal file and knocked it out. — The silent can be easily removed from the trunnion.

Installing new silents...

Silents must be positioned in a certain way; when dismantling, look at how the old ones are positioned.

Using a vice, I pressed the silent into the lever - it's easy.

But I tinkered with the silent in the trunnion for a long time))) using all sorts of improvised means, I somehow inserted the silent into the trunnion. I smeared it with soapy water and liquid soap and spat on it until I ran out of saliva. What helped me the most was a 2-jaw bearing puller. But in the end everything worked out. Getting the levers into place went quickly.

The second time, I would probably be better off going to the service station under my own control, since without the appropriate tools, repairs often take a long time and are tedious. But here a lot depends on experience.

Replacing silent blocks and levers on a Toyota Camry 40 is one of the most common types of suspension repairs.

Despite the fact that this type of repair is not the easiest, it can be performed either at a specialized service station or by the car owner independently.

If you have some special devices, replacing silent blocks is not difficult, but in some cases a hydraulic press with a force of up to 15 tons may be required.

Which material to choose - polyurethane or rubber

There are arguments in favor of rubber products, and others in favor of polyurethane ones. Having compared the positive and negative qualities of both materials, we can conclude that products made from polyurethane are more preferable.

The main arguments in favor of polyurethane:

- the material has a longer service life;

- polyurethane products are more rigid, this will make the suspension sharper and the car better controlled;

- road reagents and most chemicals do not have any serious effect on polyurethane.

The main drawback that keeps some car enthusiasts from using polyurethane parts is that after a certain period of time, polyurethane silent blocks may begin to creak. This problem can be solved by lubricating the parts with lithol or automobile oil.

Selection of new spare parts

When selecting spare parts, the manufacturer of the parts and the type of elastic element are taken into account. Factory products are made of rubber that is resistant to temperature changes and road reagents. Alternative manufacturers produce hinges filled with polyurethane, which has increased mechanical strength.

The front multi-link suspension uses 2 joints. At the rear there are 6 elements installed per side (in pairs in the longitudinal and transverse rods and in the element that regulates the angle of the wheel).

Polyurethane blocks

Polyurethane better withstands impact and bending loads, and the increased rigidity of the material increases the stability and controllability of the car. An additional advantage is the chemical inertness of polyurethane, which is not destroyed by petroleum products and road reagents.

The disadvantage of hinges is that dirt, which causes squeaks, gets into the gap between the elastic ring and the steel elements. Extraneous noise is temporarily eliminated with a few drops of oil applied under the steel rings of the silent block.

Rubber silent blocks

Rubber elastic elements have a reduced service life, but due to the elasticity of the material, the parts are easier to mount in the mounting holes (applies to horizontal hinges). The advantage of the products is the price and availability on the market of both original parts from Toyota and analogues. The front uses vertical hinges (“tablets”) with catalog codes 4865587401 (Toyota original) or 4865587401 from Daihatsu.

There are no original horizontal hinges from Toyota on the spare parts market; replacements from Masuma (article RU379) can be used.

When repairing the rear suspension, you should take into account which arm the hinge has collapsed:

- The longitudinal rod uses parts 4872503010 (in the trunnion) and 4872503010 (in the rod).

- The cross member uses hinges 4872532150 (in the trunnion) and 487252T0E0 (in the rod).

- 4872532150 (in the axle) and 487252T0E0 in the rod head are mounted in the camber rod.

How to remove suspension arms on a Camry

Replacing silent blocks with new ones is possible only after dismantling the lever. To do this you need a pit or a lift.

It is not recommended to carry out dismantling on a jacked vehicle - this can be dangerous.

Sequence of actions for dismantling the levers:

- It is necessary to loosen the nuts of the lower engine mount.

- After this, unscrew the front airbag nuts.

- Unscrew the upper right engine mount and lift the engine with a jack.

- Remove the engine mount side bolts.

- Unscrew the nuts of the longitudinal silent blocks, they are also called “candy”.

- Unscrew from the lever and remove the ball joint.

- Using a socket with an extension, unscrew the fastening of the round silent block. If necessary, you can use the pipe as an extension cord.

- Remove the levers.

After removing the old ones and installing new silent blocks, the levers return to their place, observing the reverse sequence of actions. Replacing the silent blocks of the rear suspension arms is simpler - you just need to unscrew the bolts or nuts at the mounting points.

Preparing the car for the replacement procedure

Before starting repair work, it is necessary to purchase spare parts (hinges and fasteners, old bolts and nuts are not recommended to be reused). The dismantling of the hinges is carried out on the removed suspension elements; disassembly is carried out in a garage box or on a lift . To remove silent blocks, you will need a hammer and a hydraulic press; to reduce the effort, local heating of the mounting socket with a gas burner is allowed.

Preparatory work for dismantling silent blocks in the front arms

During dismantling, it is necessary to remember or mark parts in order to correctly place other elements. Improper installation can significantly shorten the life of the new part.

It is recommended to replace levers or silent blocks in pairs.

It is not difficult to pull out worn longitudinal silent blocks of the lever, and if they are in relatively good condition, it will be quite difficult to knock them out. To facilitate the removal process, it is necessary to treat the silent blocks with WD-40 and wait a while. After this, you need to secure the levers in a vice and knock them out of their seat with several strong blows.

Removing the front and rear control arms

To remove the front control arms, you must:

- Place the machine on an overpass or a lift, and then unscrew the bolts securing the housings of the lower supports of the power unit. The cushions are secured with 3 bolts located at the bottom of the subframe and an additional bolt that can be accessed from the engine compartment. If you plan to replace horizontal silent blocks, then it is necessary to note the position of the metal rod relative to the seat in the lever on the loaded suspension.

- Remove the front wheels.

- Unscrew the lower fastening bolts; the holes in the subframe are closed with plastic plugs, which must be removed with a screwdriver.

- Loosen the top bolt connecting the support to the engine crankcase. The threaded connection can be reached from the wheel arch through the dismantled plastic shield.

- Raise the power unit with a jack or a hydraulic stand with a wooden spacer (rest the support against the line of junction of the engine crankcases and the gearbox).

- Remove the support from the mounting socket, which will allow you to unscrew the nuts securing the horizontal silent block.

- Unscrew the bolts securing the horizontal hinges and ball joints.

- Loosen the bolt securing the vertical hinge (“tablet”). It is recommended to carry out the work using a wrench with an extension, which reduces the force when unscrewing the threaded connection.

- Remove the lever together with the installed silent blocks.

To disassemble the rear suspension, you need to place the car on a lift, and then remove the rims and tires. Then you need to unscrew the bolts securing the rod in which you plan to change the hinges. Since threaded connections are covered with a layer of rust, it is recommended to treat the surface with a liquid with increased penetrating ability (for example, WD40).

If the camber lever is removed, then after completion of the repair work the angles of the rear wheels are adjusted (the adjustment is carried out on an electronic stand).

Algorithm for installing new silent blocks

The procedure for installing the silent blocks of the front suspension arm on a Camry:

- It is necessary to thoroughly clean the installation site of the new part.

- Treat these areas with primer to protect the lever from rust.

- Lubricate the holders with Litol type lubricant. This will help press the part in and prevent squeaks during operation. Recommended for products and polyurethane.

- There are usually no problems with installing a round silent block. They fit in quite easily, in this case it is recommended to weld the clips to the lever by spot welding in several places.

- The longitudinal silent block always enters with difficulty, even when using special lubricant. To install it, you need to hold the lever in a vice and use a hammer to hammer the part into place. The main thing is to watch which side the protective edge is on.

After installing the new parts, the levers are mounted back to their places.

Many non-original round front arm bushings are produced slightly smaller in height. During installation, it is recommended to use two millimeter washers.

What you need to know about silent blocks

The manufacturer does not provide for the possibility of replacing the silent blocks of the arms, both front and rear suspension. If repairs are necessary, you need to buy the lever assembly. But there is still a way out. There are several brands of non-original silent blocks on the auto parts market. The quality of the products offered is often not inferior to original spare parts.

If the following symptoms occur, it is necessary to replace the levers or silent blocks:

- occurrence of “play” in the wheel;

- violation of the wheel alignment angle;

- the appearance of extraneous sounds and knocks in the chassis of the car while driving over uneven surfaces.

Silent blocks that have lost their properties negatively affect the vehicle's handling. This may cause an accident.

Any replacement of the lever or its silent block on a Camry in the 40 body leads to a change in the angle of the wheels and requires their adjustment.

Installation of floating rear control arm bushings

On a Toyota Camry 40, the installation of new silent blocks on the rear control arms is carried out in the same way as on the front ones: cleaning, painting and processing the seat. To install the new silent block into the rear trailing arm, you need to use a vice. During the pressing process, it is important to install the new part evenly to avoid misalignment and jamming halfway through the stroke.

It is necessary to observe the position of the new parts by analogy with the old ones.

After replacing the silent blocks, the rear trailing arm is installed in its place.

The most complex and time-consuming process is replacing the floating bushings of the rear wishbones. They are produced without a metal base with sides along the edges, which prevent them from being properly installed in their place.

It is recommended to use special equipment for installation. It can be made from a piece of pipe 20 cm long. This pipe should be on one side the diameter of the silent block, and on the other side should be slightly larger than this. You should get a kind of cone.

Passing through such a device, the bushing gradually compresses to the desired size, which facilitates the installation process. To simplify, you can cut off the rubber side on one side of the part. Without such a frame, it is very difficult to change floating bushings. It will be especially difficult to press in the rear silent blocks made of polyurethane, since they are much stiffer than rubber ones.

| Replacing the air filter | |

| Replacing the cabin filter | |

| Replacing steering rods | News |