Let's move on directly to the procedure for replacing silent blocks.

Video of replacing trailing arm silent blocks in Toyota Camry 40

Backup video on how to replace the rear axle trailing arm silent blocks in a Toyota Camry XV40:

One of the popular, but far from simple types of suspension repairs is replacing silent blocks on a Toyota Camry . This procedure can easily be performed by car owners themselves, and does not require special or complex equipment. But you need to take into account that in some cases, installing a new silent block may require a powerful press with a pressure of up to 10 tons.

This is interesting: Removal and installation of manual and robotic transmissions of Toyota Corolla

Replacing the rear wishbone of the rear suspension

We install the car on a lift or inspection ditch

Raise the rear of the car and remove the wheel

Unscrew the nut securing the rear wishbone to the rear suspension knuckle

Unscrew the bolt securing the rear wishbone to the cross member of the rear suspension

Remove the bolt securing the lever to the rear suspension knuckle and remove the lever

We examine the lever. If there is deformation, wear and damage to the threads of the adjusting coupling, as well as wear of the silent block, replace the lever.

Install the parts in reverse order

The paint mark on the lever should face backwards

The nut and bolt securing the lever are finally tightened with the car standing on the ground to a torque of 100 Nm

We check and, if necessary, adjust the wheel alignment angles

Replacing the rear suspension trailing arm

We install the car on a lift or inspection ditch

Raise the rear of the car and remove the wheel

Unscrew the bolt securing the parking brake cable holder and remove the cable from the front trailing arm hinge bracket

Unscrew the nut and remove the bolt securing the trailing arm to the body bracket

Unscrew the nut, remove the bolt securing the trailing arm to the rear suspension knuckle and remove the arm

We examine the lever. If there are cracks, deformation or wear of the silent block, replace the lever.

Signs of wear of the silent block are ruptures, one-sided swelling and detachment of rubber from the metal bushing

Install the parts in reverse order

We finally tighten the lever mounting bolts with the car standing on the ground to a torque of 113 Nm

Removing and installing the rear suspension cross member

We install the car on a lift or inspection ditch

Raise the rear of the car and remove the wheel

We jack up the rear suspension knuckle through a wooden block

Unscrew the nut securing the rear wishbone to the rear suspension knuckle, holding the bolt from turning

Remove the bolt and disconnect the lever from the knuckle

In the same way, disconnect the front wishbone from the rear suspension knuckle.

Removing the rear anti-roll bar

Remove the left and right rear suspension cross member mounting brackets by unscrewing two nuts on each bracket

We install reliable supports under the crossbar

Unscrew the two bolts and remove the cross member assembly with transverse arms

Install the rear suspension cross member in the reverse order

We finally tighten the nuts securing the transverse arms with the car standing on the ground to a torque of 100 Nm

We check and, if necessary, adjust the wheel alignment angles

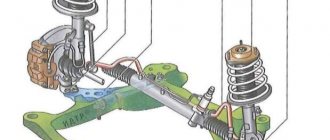

Car rear suspension diagram

Toyota Camry is one of the most popular cars among Russian car enthusiasts. Using the V40 as an example, let’s look at what elements the rear suspension assembly consists of:

- upper spring support;

- spring;

- shock absorber strut;

- the lower arm is where it is attached;

- rubber bushings.

A similar rear suspension of the Toyota Camry V40 with a MacPherson strut contains longitudinal and transverse arms. In addition, Camry 40 models have stabilizers that provide lateral stability. This type of rear suspension is simple and compact, and has better wheel kinematics.

Toyota front suspension diagram

This Camry V40 circuit, like other models, consists of the following basic elements:

- upper shock absorber support;

- strut bearing;

- spring socket;

- rubber cover that protects from moisture, dust, etc.;

- cylindrical spring;

- rebound limiter;

- gasket for spring;

- shock absorber strut.

This unit for the Camry 30 and its improved models reduces vibrations, ensures a smooth ride and, together with the hydraulic brake system, increases the stability of the vehicle, including on slippery roads.

Front suspension arm

This structure is connected to the steering knuckle; a stabilizer responsible for lateral stability is also attached to it. The material for it is spring steel. The result of the lever's operation is to reduce the car's roll when cornering. The lever is replaced when it is impossible to repair the suspension, and for safe and comfortable movement it is necessary to perform an update.

They do it for the following reasons:

- the geometry of the lever has changed as a result of deformation or mechanical damage;

- Excessive wear at the bushing attachment point;

- failure of the ball joint or silent block and other reasons.

Camry rear suspension system repair

The rear system, like the front one, is a connecting element for the body and wheels of the car. The question of its repair arises when discomfort appears when moving (lateral rocking, vibration, etc.). Having determined the malfunction, we proceed to repair or replace the defective elements.

- raise and secure the machine;

- remove the wheel;

- install a support;

- loosen the shock absorber mounting bolt at the bottom;

- loosen the upper mounting bolts of the rack;

- remove the shock absorber;

- install a new spare part, tighten the upper bolts and install the lower connection;

- remove the shock absorber strut;

- mount the wheel;

- lower the car;

- To avoid distortion of the bushings, tighten the fastening bolt at the bottom.

Rear suspension silent blocks

A rubber-metal hinge or silent block consists of two metal tubes of different diameters, between which there is an insert made of polyurethane, rubber or other durable material. This hinge element is the fastening material for the suspension system. With long-term use, the silent block eventually loses its qualities due to wear and starts to knock.

Photo of car interior reupholstery

Practice shows that a spare part with a polyurethane base increases the stability and controllability of the car compared to conventional ones.

Knock in the front suspension, why it rattles, causes and solutions One of the signs of unsuitable silent blocks is a knock in the front suspension, which at the initial stage can be periodic. In addition to the fact that it rattles in the front and the car's handling is reduced, the tires wear out unevenly. To obtain confirmation of suspected problems, you need to perform a number of simple steps:

- place the car on a level surface;

- verify the integrity of the springs visually or by measuring the ground clearance;

- rock the car to make sure that the damping is not disturbed.

Next, place the car on a lift and inspect for shock absorber leaks, cracks, traces of impacts and other damage to system elements.

Using a pry bar, we check all bushings and connecting elements for play and wear.

When carrying out diagnostics, maintenance or repair work, a visual inspection of hinges, protective covers, struts, bushings, etc. is carried out. The presence of cracks, deformations and other defects requires their replacement.

Silent blocks replaced at the wrong time can not only lead to the consequences already listed, but will also require replacement of the suspension system, and can also lead to tragic consequences.

Let's sum it up

As you can see from the article, you can fix rear and front suspension problems in a car yourself. If malfunctions occur, they should be corrected immediately, since your safety depends on it.

Toyota Cam ry (2005+). FRONT SUSPENSION

The front suspension is independent, MacPherson strut type, with telescopic shock absorbers, coil springs, lower wishbones and anti-roll bar.

- Noise and knocking when the car is moving

- Moving a vehicle away from straight-line motion on a horizontal road

- Excessive or uneven tire tread wear

Toyota Camry body stubbornly resists rust

Toyota Camry body, which is resistant to corrosion , has a rather weak paint coating that is easily scratched and dulled by frequent washing. But in fairness, it is worth noting that you will not see rust on the body. Although chips appear quite quickly, the damaged areas of the body do not succumb to the oxidation process even over time.

But literally after two or three winters the chrome parts of the body become cloudy and become ugly in the form of red-brown stains.

The paint on the windshield wiper arms also swells, cracks and peeling quickly appear on the decorative trim of the trunk lid, and the coating of alloy wheel rims peels off.

The chemicals that utility workers pour on our roads in abundance during the cold season are to blame for everything.

Suspension parts

Stabilizer struts (1,100 rubles each) are guaranteed to withstand 50-70 thousand km, and often more. But the bushings (480 rubles each) of both stabilizers are changed, as a rule, before the struts, shock absorbers (on average 4500 rubles for the front and rear) have to be updated closer to 100 thousand km. Ball joints (2,500 rubles each) last one and a half times longer. The steering rack is also long-lived. Its resource averages 180-200 thousand km.

Why is the car not for sale?

, steering rods can withstand 130 thousand km (1,800 rubles each). The steering shaft universal joint wears out ahead of schedule, and the oil seals and high-pressure hose of the power steering pump may leak.

the front discs often warp from overheating, and by 100 thousand km the calipers , which are recommended to be lubricated at every maintenance.

Engine

the engine and air conditioning radiators every two years . Otherwise, the cylinder head will suffer from overheating. By 100 thousand km, the drive belt tensioner usually wears out. And the imminent death of the water pump is indicated by traces of antifreeze under the hood and increased noise from the pump.

The main problem is oil leakage due to a leaky oil cooler pipe. Since 2009, the oil line became all-metal, and the problem went away. The company conducted a recall campaign on this topic.

Electrical equipment

The electrical equipment of the Toyota Camry is traditionally reliable. True, network failures occur periodically, however, they are not widespread. The headlights and interior lighting bulbs burn out, but replacing them is cheap.

Regarding electrics, it is worth giving an example of replacing the engine compartment wiring: Toyota Camry 2009, ACV 40 body, 2AZ-FE 2.4 liter engine. The car stalled when switching the automatic gearbox selector.

What you need to know about silent blocks

The manufacturer does not provide for the possibility of replacing the silent blocks of the arms, both front and rear suspension. If repairs are necessary, you need to buy the lever assembly. But there is still a way out. There are several brands of non-original silent blocks on the auto parts market. The quality of the products offered is often not inferior to original spare parts.

If the following symptoms occur, it is necessary to replace the levers or silent blocks:

- occurrence of “play” in the wheel;

- violation of the wheel alignment angle;

- the appearance of extraneous sounds and knocks in the chassis of the car while driving over uneven surfaces.

Silent blocks that have lost their properties negatively affect the vehicle's handling. This may cause an accident.

Any replacement of the lever or its silent block on a Camry in the 40 body leads to a change in the angle of the wheels and requires their adjustment.

Which replacement parts to choose?

There are many arguments both in favor of polyurethane silent blocks and in defense of rubber ones. But if you approach the issue with complete objectivity, then the choice definitely falls towards polyurethane products. There are many reasons for this:

- the material is more durable;

- silent blocks made of polyurethane are more rigid, which ensures the suspension is collected;

- polyurethane is not susceptible to the negative effects of road reagents and other chemicals.

The only drawback due to which the replacement of silent blocks on Camry 30 and other bodies is carried out using rubber - polyurethane begins to creak over time. But this problem can be solved by periodically lubricating the seats with a regular oil can.

Front suspension arm silent block v40

Gentlemen, what kind of vertical silent block should I put in the v40 front suspension arm?

I have studied the forum far and wide. There are options:

1) new lever original 48068-33060 and 48069-33060. About 3000r. for one lever.

2) silent block FEBEST TAB-045. about 350r for 1 piece. Judging by the reviews on the forum, it runs up to 10,000 km.

3) silent block made of polyurethane. There is some lack of trust.

4) find the same silent original Toyota or Daihatsu. Most likely this is the best option. Does anyone have information on the articles?

Does everyone really install new levers or change FEBEST every 10,000?

The “original” silent tablet is 48655-87401 Daihatsu/Toyota https://www.camry-club.ru/forum/showt. veski-v30

but we still haven’t been able to find the candy

Absent83

, in addition to above. RBI T24C04WB ASVA TAB-280

The “original” silent tablet is 48655-87401 Daihatsu/Toyota https://www.camry-club.ru/forum/showt. veski-v30

but we still haven’t been able to find the candy

Now this is the lowest price on japancars.ru Just a long wait. But it's not a problem.

As for 48655-87401 Daihatsu/Toyota - it’s 30 as far as I remember. Or does it also go to 40? [COLOR=”Silver”]

———- Message added at 19:48 ———- Previous message was at 19:46 ———-

Select/add what to put:

1) new lever original 48068-33060 and 48069-33060. About 3000r. for one lever (Now this is the lowest price on japancars.ru)

2) silent block FEBEST TAB-045. about 350r for 1 piece. Judging by the reviews on the forum, it runs up to 10,000 km.

3) silent block made of polyurethane. There is some lack of trust.

4) find the same silent original Toyota or Daihatsu. Most likely this is the best option. Does anyone have information on the articles?

What to put? Will the silent tape completely break soon?

According to reviews, it will do. It’s better to order the original. Try to install it. It’s not that much money, and if it doesn’t fit, then. Some people generally take the assembled lever at a disassembly with original silents at a price of 1000 rubles. Also an option. The original number was given to you

In Ekb they ask 4000 rubles for a used lever. when you tell them that a new one costs 3700, they say that they have almost a new one here and now, but for 3700 you have to wait a week.

What are you betting on? is it really used for that kind of money?? Surely a replacement has been found.

How to remove front and rear control arms

It should be taken into account that replacing silent blocks on Camry 40 , 50 and 30 bodies is possible only with the levers removed. To dismantle them you will need an inspection hole. As a last resort, you can jack up the car, place it on stands and remove the wheels.

How to remove front and rear arms when replacing silent blocks on a Camry

To remove the front control arms, perform the following steps:

- Unscrew the nuts securing the right and left airbags. Unscrew three nuts from the beams and one from the motor.

- Then unscrew the 2 nuts holding the front lower cushion.

- The top motor mount installed on the left side must be unscrewed.

- Using a jack, the engine and gearbox are raised.

- The bolts installed on the sides of the cushions are completely unscrewed, then they are removed.

- The bolts securing the “candies”—the longitudinal silent blocks of the front arm—are unscrewed.

- Then unscrew 2 nuts and 1 bolt securing the ball joint to the lever.

- From under the car, using a pipe wrench (for reinforcement), the bolt securing the second silent block - the “tablet” - is torn off.

- After unscrewing the bolt, nothing holds the levers in place and they can be removed.

When the front silent blocks are replaced on a Toyota Camry , the levers are installed in the reverse order. Removing the rear arms is much easier - just unscrew the mounting bolts.

This is interesting: Checking the level and adding fluid to the windshield washer reservoir of Toyota RAV4

Toyota Camry suspension

The main function of the suspension is to link the wheels and body parts into a single structure. Thanks to the suspension, the force that affects the wheels is transmitted to the body. It includes a number of parts (shock absorbers, springs, etc.) that ensure vehicle stability when cornering and maneuvering, reduce body vibrations and weaken dynamic loads.

In addition, the smoothness, comfort and safety of passengers and the driver depend on it. Cars of this model have rear and front independent MacPherson suspension.

Remember! In order for these structures to have a long service life, it is necessary to constantly monitor the condition of the Camry 30 suspension and its other modifications.

Car rear suspension diagram

Toyota Camry is one of the most popular cars among Russian car enthusiasts. Using the V40 as an example, let’s look at what elements the rear suspension assembly consists of:

- upper spring support;

- spring;

- shock absorber strut;

- the lower arm is where it is attached;

- rubber bushings.

A similar rear suspension of the Toyota Camry V40 with a MacPherson strut contains longitudinal and transverse arms. In addition, Camry 40 models have stabilizers that provide lateral stability. This type of rear suspension is simple and compact, and has better wheel kinematics.

Toyota front suspension diagram

This Camry V40 circuit, like other models, consists of the following basic elements:

- upper shock absorber support;

- strut bearing;

- spring socket;

- rubber cover that protects from moisture, dust, etc.;

- cylindrical spring;

- rebound limiter;

- gasket for spring;

- shock absorber strut.

This unit for the Camry 30 and its improved models reduces vibrations, ensures a smooth ride and, together with the hydraulic brake system, increases the stability of the vehicle, including on slippery roads.

Front suspension arm

This structure is connected to the steering knuckle; a stabilizer responsible for lateral stability is also attached to it. The material for it is spring steel.

The result of the lever's operation is to reduce the car's roll when cornering.

The lever is replaced when it is impossible to repair the suspension, and for safe and comfortable movement it is necessary to perform an update.

They do it for the following reasons:

- the geometry of the lever has changed as a result of deformation or mechanical damage;

- Excessive wear at the bushing attachment point;

- failure of the ball joint or silent block and other reasons.

Camry rear suspension system repair

The rear system, like the front one, is a connecting element for the body and wheels of the car. The question of its repair arises when discomfort appears when moving (lateral rocking, vibration, etc.). Having determined the malfunction, we proceed to repair or replace the defective elements.

- raise and secure the machine;

- remove the wheel;

- install a support;

- loosen the shock absorber mounting bolt at the bottom;

- loosen the upper mounting bolts of the rack;

- remove the shock absorber;

- install a new spare part, tighten the upper bolts and install the lower connection;

- remove the shock absorber strut;

- mount the wheel;

- lower the car;

- To avoid distortion of the bushings, tighten the fastening bolt at the bottom.

Rear suspension silent blocks

A rubber-metal hinge or silent block consists of two metal tubes of different diameters, between which there is an insert made of polyurethane, rubber or other durable material. This hinge element is the fastening material for the suspension system. With long-term use, the silent block eventually loses its qualities due to wear and starts to knock.

Practice shows that a spare part with a polyurethane base increases the stability and controllability of the car compared to conventional ones.

Knock in the front suspension, why it rattles, causes and solutions One of the signs of unsuitable silent blocks is a knock in the front suspension, which at the initial stage can be periodic. In addition to the fact that it rattles in the front and the car's handling is reduced, the tires wear out unevenly. To obtain confirmation of suspected problems, you need to perform a number of simple steps:

- place the car on a level surface;

- verify the integrity of the springs visually or by measuring the ground clearance;

- rock the car to make sure that the damping is not disturbed.

Next, place the car on a lift and inspect for shock absorber leaks, cracks, traces of impacts and other damage to system elements.

Using a pry bar, we check all bushings and connecting elements for play and wear.

When carrying out diagnostics, maintenance or repair work, a visual inspection of hinges, protective covers, struts, bushings, etc. is carried out. The presence of cracks, deformations and other defects requires their replacement.

Silent blocks replaced at the wrong time can not only lead to the consequences already listed, but will also require replacement of the suspension system, and can also lead to tragic consequences.

Preparing to replace silent blocks

It is very important to remember the installation locations before removing old elements - if new ones are installed incorrectly, their service life will be significantly reduced. It is necessary to mark installation locations for all groups of parts.

Important point! Silent blocks are replaced only in pairs! It is not permissible to replace parts on only one of the levers.

After removing the levers, you can begin to remove the old silent blocks. Relatively intact “candies” are usually difficult to knock out, while heavily worn ones can be easily squeezed out with a finger with little effort. To simplify the dismantling process, it is recommended to spray them with WD and wait a few minutes until the composition is absorbed. Then a couple of strong and precise blows with a hammer - and the “sweets” literally fly out of the nest.

Preparing to replace silent blocks on a Camry

With “tablets” you usually have to seriously suffer - often an ordinary vice is not enough to squeeze them out of their seat. As an alternative, you can thoroughly heat part of the lever with a gas or gasoline burner, and then knock out the burnt silent blocks. Otherwise, you will have to look for a multi-ton press to squeeze them out.

Preparing to replace silent blocks on a Camry

After removing the bushings and thoroughly cleaning the seats, all that remains is to replace the silent blocks of the front levers on Camry 40 , 50 or 30 and their subsequent installation in place. There are usually no difficulties with the bushings of the rear levers: just cut off the rubber collar with a sharp knife, secure the lever in a vice and knock out the bushing along with the holder. To facilitate dismantling, you can also thoroughly warm up the seats.

Front elements: features

If the car has wear on the stabilizer link, bushings with a small diameter are used.

Replacing parts for front arms:

- To raise the “iron horse”, use a jack, then remove the wheel.

- After this, the search begins for the bolt securing the silent block and unscrewing it.

- At the same time, the nut securing the rear element is unscrewed.

- It is necessary to pull the stand together with the lever towards you.

- After pulling out, the bolts that secure the lever to the support are unscrewed.

- Dismantling the lever is the next stage of work on replacing silent blocks.

- Pressing out the rear block of the front lever using a sledgehammer.

- To press a new part, it is best to use a special device. Special equipment is usually used, but a regular sledgehammer or hammer can be a good helper in this matter.

- Assembly work with the lever backwards is carried out in strictly reverse order, then all the automotive elements that were dismantled are put back into place.

During the work, it is necessary to take into account the fact that the front element can be tightened on a car that is removed from the jack.

During the final work, it is important to remember the need to restore wheel alignment.

How to remove suspension arms on a Camry

Replacing silent blocks with new ones is possible only after dismantling the lever. To do this you need a pit or a lift.

It is not recommended to carry out dismantling on a jacked vehicle - this can be dangerous.

Sequence of actions for dismantling the levers:

- It is necessary to loosen the nuts of the lower engine mount.

- After this, unscrew the front airbag nuts.

- Unscrew the upper right engine mount and lift the engine with a jack.

- Remove the engine mount side bolts.

- Unscrew the nuts of the longitudinal silent blocks, they are also called “candy”.

- Unscrew from the lever and remove the ball joint.

- Using a socket with an extension, unscrew the fastening of the round silent block. If necessary, you can use the pipe as an extension cord.

- Remove the levers.

After removing the old ones and installing new silent blocks, the levers return to their place, observing the reverse sequence of actions. Replacing the silent blocks of the rear suspension arms is simpler - you just need to unscrew the bolts or nuts at the mounting points.

Suspension diagram for Toyota Camry

Toyota Camry is one of the most popular modern cars, selling 800,000 - 1,000,000 units annually, making this model 3-5 in the list of best-selling models year after year.

This car was originally intended for sale in Japan, but the company changed its development sector and began producing Camry for the whole world.

In our country, the most popular models were Camrys from the fifth to the seventh versions in bodies 30, 40 and 50.

- 1 Fifth generation

- 2 Sixth generation

- 3 Seventh generation

Fifth generation

The fifth generation Camry was produced from 2001 to 2006. Compared to previous generations, the car has become larger and the interior has increased. The wheelbase of the model was 2.72 cm in length, and the width also became 7 cm larger, which made it possible to slightly change the design of the front axle shaft, placing the wheels closer to the outer corners, which helped the car become more stable on the road surface.

The front and rear suspension schemes in the car are unchanged - independent MacPherson struts with anti-roll bars, with a double locking arm and springs. The lower front MacPherson arm is attached to the steering knuckle, and the anti-roll bar is attached to the lower arms.

The most non-standard solution in the fifth generation was that in the front suspension design, the kingpin axis is located in front of the steering knuckle, which allows for better stabilization of the car during straight-line motion. The structure of each of the two suspensions includes:

- top support;

- washers;

- cylindrical spring;

- silent blocks used for attaching arms, anti-roll bar;

- shock absorber strut;

- location for fixing the lower arm;

- spherical type bushing.

Important! In the rear axle shaft, engineers increased the wheel travel, which allowed the car to be much more comfortable and to drive better on bad roads and gravel. The front suspension is equipped with a speed sensor (ABS).

Sixth generation

The sixth generation Camry was sold from 2006 to 2011. The 2006-2011 Camry received not only a new body, but a completely different chassis design, which began to cope with the road many times better.

The front suspension is an independent MacPherson strut suspension with anti-roll bar, shock absorber struts, coil springs and wishbones.

The structure of the axle shaft itself is not very different from the previous generation, but it is worth understanding that the telescopic shock absorber struts have been improved, which makes it possible to better stabilize the car body in a vertical position.

The shock absorber strut, according to the user manual and construction diagrams, now consists of:

- shock absorber;

- compression buffer;

- protective cover;

- bottom spring gaskets;

- upper spring plate;

- support bearing;

- top support;

- springs and nuts.

Repair and maintenance of the front axle shaft should be carried out every maintenance or every 15-25,000 km, depending on what roads the car is driven on.

At the rear of the car, it was no longer MacPherson strut, as in a generation earlier, but a multi-link axle shaft, consisting of two transverse and one longitudinal locking lever, telescopic shock absorbers, coil springs, a stabilizer bar and a bar.

It is worth noting that in the sixth generation the car received a lot of new electrical equipment, including new body stabilization systems, electro-hydraulic power steering in the most equipped configurations.

Seventh generation

The production of the seventh generation Camry began in 2011, and production of the model ended in 2021. In this generation, the company’s engineers tried to do everything in such a way as to save the future owner of the car from the “whims” of past Camry versions. Thus, the car received a longer wheelbase - 2.775 m, the front track is 1.575 m wide, while the rear one is 1.565 m.

Preparatory work for dismantling silent blocks in the front arms

During dismantling, it is necessary to remember or mark parts in order to correctly place other elements. Improper installation can significantly shorten the life of the new part.

It is recommended to replace levers or silent blocks in pairs.

It is not difficult to pull out worn longitudinal silent blocks of the lever, and if they are in relatively good condition, it will be quite difficult to knock them out. To facilitate the removal process, it is necessary to treat the silent blocks with WD-40 and wait a while. After this, you need to secure the levers in a vice and knock them out of their seat with several strong blows.

With round silent blocks it is often more difficult. The force of a conventional vice may not be enough and knocking it out with a hammer will also not work. In this case, you can try to warm up the seat with a gas burner and then try to knock out the silent block. If this does not work, you will need to squeeze out the silent blocks with a special hydraulic press.

After removing the old elements from the lever, it is necessary to thoroughly clean the seats and install new parts.

Removing the silent blocks of the rear levers is easier. It is necessary to hold the lever in a vice, cut off the rubber side and knock out the clip with a hammer.

It is allowed to heat the seat using a gas burner.

Which material to choose - polyurethane or rubber

There are arguments in favor of rubber products, and others in favor of polyurethane ones. Having compared the positive and negative qualities of both materials, we can conclude that products made from polyurethane are more preferable.

The main arguments in favor of polyurethane:

- the material has a longer service life;

- polyurethane products are more rigid, this will make the suspension sharper and the car better controlled;

- road reagents and most chemicals do not have any serious effect on polyurethane.

The main drawback that keeps some car enthusiasts from using polyurethane parts is that after a certain period of time, polyurethane silent blocks may begin to creak. This problem can be solved by lubricating the parts with lithol or automobile oil.

Installation procedure for front silent blocks

Replacing the silent blocks of the front levers on a Toyota Camry is performed as follows.

- The seats are thoroughly cleaned of rubber residues. If the replacement is being carried out for the first time, then these remnants will be more than enough.

- The inside of the lever is covered with one layer of primer paint. This is necessary to protect the metal from corrosion.

- Then the clips are lubricated with Litol, or better yet, with a special lubricant for installing silent blocks. It not only makes it easier to press in the bushings, but also helps to avoid squeaking in the future, especially if polyurethane products are used for replacement.

- The "pills" usually go in fairly easily. Therefore, in order to avoid their displacement, it is recommended to grab the clips on both sides by spot welding.

- When installing the “candies” you will have to work hard - even with the use of special lubricant they fit quite tightly. To install them, you need to securely fix the lever in a vice, substitute the “candies,” and gradually drive them into the holder with strong, precise blows of a rubber hammer. In this case, their limiting collar must be installed in the front part of the lever.

At this point, the replacement of the front silent blocks on the Camry 40 or other bodies is completed, and you can begin installing them in place.

The procedure for installing front silent blocks on a Camry

It is important to know! Most non-original “tablets” are produced 2 mm shorter than the standard ones. Therefore, when installing the lever in place, you need to place 2 washers 1 mm thick on both sides of the silent block.

Replacement of front silent blocks of front levers of Toyota Camry CV40.

Replacing silent blocks is a fairly common procedure. We will now consider an example of such a procedure. The front control arms on the Toyota Camry are quite simple and reliable; the ball joint on them is attached separately and does not require replacement.

To remove the lever, we need to unscrew the bolt and two nuts securing the lever to the ball joint. Access to the front silent block is blocked by the engine mount. In order to remove it, we need to support the engine and remove the cushion.

After removing the pillow, access to the mounting bolts is freed and we can freely unscrew them.

There are several ways to press out the old silent block and press in the new one. One of them, more common, is pressed out using a press. But installing the lever in the press is not very convenient. And some craftsmen prefer to secure the lever in a vice and knock out the silent block and hammer a new one back in. It must first be lubricated with soap or gel, but not oil, so that it can easily move into its seat. The second method applies only to the front silent block. We must not forget about the direction and a certain angle of attachment of the silent block. In both cases, you need to have certain technical skills.

We secure the fastenings of the front and rear silent blocks, tighten the fastenings of the ball joint and install the engine mounting cushion. After replacing the silent blocks, it is imperative to adjust the alignment

.

Replacement procedures are identical on both sides. The photo clearly shows the peeling of the top layer of the silent block.

This is the replacement of the silent blocks of the front levers of the Toyota Camry

finished.

All work was carried out in our car service center "Toyota - Lyublino"

You can find out the cost of replacing silent blocks HERE

For unclear questions and to make an appointment, call the number - +7(495)-507-16-41

The silent blocks of the front levers of the Toyota Camry V40 have to perform important functions. The parts ensure the damping of vibrations that occur during movement, and also help prevent unforeseen and sometimes dangerous situations.

Peeling of the rubber, as well as the appearance of roughness on its surface, is strictly unacceptable. It is important that the upper part is smooth, there are no cracks or play on it, since such imperfections can result in destruction in the area of the parts’ seats.

Uneven wear on the tires indicates that it is time to replace the silent blocks on the Camry 40, or it is necessary to carry out urgent car repairs.

The hinges are also mounted in other system components of the car - gearbox, engine element, lever mounts, shock absorbers. During operation of the machine, the blocks are subject to noticeable loads; it is necessary to monitor their general position and replace them regularly. It is advisable to carry out inspections every 50,000 km traveled. To determine their condition, it is necessary to check the play and inspect the parts, as well as the rubber insert between them: if cracks and peelings are detected, it is important to carry out work - replacing silent blocks in accordance with the necessary standards, subtleties and rules.

Installation of floating rear control arm bushings

On a Toyota Camry 40, the installation of new silent blocks on the rear control arms is carried out in the same way as on the front ones: cleaning, painting and processing the seat. To install the new silent block into the rear trailing arm, you need to use a vice. During the pressing process, it is important to install the new part evenly to avoid misalignment and jamming halfway through the stroke.

It is necessary to observe the position of the new parts by analogy with the old ones.

After replacing the silent blocks, the rear trailing arm is installed in its place.

The most complex and time-consuming process is replacing the floating bushings of the rear wishbones. They are produced without a metal base with sides along the edges, which prevent them from being properly installed in their place.

It is recommended to use special equipment for installation. It can be made from a piece of pipe 20 cm long. This pipe should be on one side the diameter of the silent block, and on the other side should be slightly larger than this. You should get a kind of cone.

Passing through such a device, the bushing gradually compresses to the desired size, which facilitates the installation process. To simplify, you can cut off the rubber side on one side of the part. Without such a frame, it is very difficult to change floating bushings. It will be especially difficult to press in the rear silent blocks made of polyurethane, since they are much stiffer than rubber ones.

It so happens that replacing the rear wishbone silent blocks takes more time than replacing all the others combined.

| Name | Manufacturer | vendor code | Price, rub |

| Front lever silent block “round” | Toyota | 4865587401 | 1800 |

| Subaru | 20204AJ020 | 830 | |

| Masuma | RU380 | 416 | |

| RBI | T24C04WB | 360 | |

| Cross silent block of the front arm | Toyota | 4865433050 | Out of stock |

| Masuma | RU379 | 543 | |

| RBI | T24C04WC | 490 | |

| Rear wishbone inner silent block | Toyota | 487252T0E0 | Out of stock |

| Masuma | RU389 | 360 | |

| RBI | T25C04E | 241 | |

| Outer rear wishbone silent block | Toyota | 4872532150 | 1150 |

| Subaru | 20251AA021 | 180 | |

| RBI | T25081 | 213 | |

| Rear trailing arm silent block | Toyota | 4872503010 | 458 |

| RBI | T25C020 | 240 |

Repair process

- Installing the car on a lift. To replace, the car is raised on a two-post lift.

- Then the front wheels are dismantled.

- Then the lower side supports of the internal combustion engine are dismantled; to do this, their threaded connections are cleaned and filled with penetrating lubricant. After that, the nuts securing the supports can be easily unscrewed with a pneumatic impact wrench.

- Now, for convenience, the plastic dirt-proof cover will be removed.

- Removing the casing. It is mounted on two M10 bolts and one piston.

- Dismantling levers. Use a wrench to unscrew the upper nut of the engine support.

- Removing the suspension. Then the bolts securing the ball joint to the lever are unscrewed.

- Toyota car repair process. The pins are pulled out from the guides. Now the lever is held by two silent blocks.

- Raising the internal combustion engine. Using a special hydraulic rack with a spacer, so as not to damage the engine sump, the engine is raised.

- The support is pulled out.

- General view of the engine support.

- Removing the suspension arm. Now you can get to the two bolts that secure the front silent block to the front suspension subframe.

- Removing the lower arm. They are unscrewed with a pneumatic gun.

- Removing the lever. The rear silent block bolt is loosened. After which the old lever is dismantled.

- General view of the old and new suspension arm.

- General form. Lever seat.

- The new lever is installed in place.

- Installing a new lever. Screw on two bolts of the front silent block.

- Lever tightening. Then the rear silent block. The nuts are tightened to a certain tightening torque specified by the manufacturer.

- Installation of engine support. The engine support is installed in place.

- Installation of engine support. We lower the internal combustion engine using the same hydraulic strut.

- Final operations. The ball joint and the engine support are screwed on. The mudguard is installed back. The wheel is screwed and tightened with a torque wrench. Similar operations are performed on the other side of the car. After assembly

admin2017-04-22T21:50:06+03:00