Toyota 4E-FE is a 1.3 liter (1331 cc) four-cylinder, 4-stroke petrol engine from the Toyota E-family. The Toyota 4E-FE engine was manufactured since 1989 and was discontinued after 1999.

The 4E-FE engine features a cast iron block and aluminum cylinder head with dual overhead camshafts (DOHC) and four valves per cylinder (16 total). The compression ratio is 9.6:1. It has a bore of 74.0 mm and a stroke of 77.4 mm. The Toyota 4E-FE engine has an electronic fuel injection system and a distributor ignition system.

The engine produces power from 75 hp. (55 kW; 74 hp) at 5400 rpm up to 100 hp (74 kW; 99 hp) at 6600 rpm maximum power and from 110 N m (11.2 kg m) at 3600 rpm - 117 N m (11.9 kg m) at 4000 rpm peak torque.

During production, three generations of the 4E-FE engine were available. The engines featured mainly modified intake and exhaust manifolds and an ECU, resulting in different power output and torque.

The engine code breakdown is as follows:

- engine 4 - 4 generations

- E - engine family

- F - Economical narrow-angle DOHC

- E - multipoint fuel injection

| Engine characteristics 4E-FE | |

| Engine code | 4E-FE |

| View | Four-stroke Inline-4 (Straight-4) |

| Fuel type | Petrol |

| Years of production | 1989-1999 |

| Volume | 1.3 l, 1331 cm 3 (81.22 c.u.) |

| Fuel system | Electronic fuel injection (EFI) |

| Turbine | — |

| Horsepower | From 75 hp (55 kW; 74 hp) at 5400 rpm up to 100 hp (74 kW; 99 hp) at 6600 rpm |

| Torque | 110 N m (11.2 kg m) at 3600 rpm to 117 N m (11.9 kg m) at 4000 rpm |

| Cylinder operating order | 1-3-4-2 |

| Dimensions (L × H × W) | — |

| Weight | — |

Technical specifications 3L 2.8 l/91 l. With.

Initially, the 2.8 liter L-family engine used vortex combustion chambers. The in-line 4-cylinder engine design balances vibrations, horizontal and vertical forces.

An important feature was the presence of valve/piston collision when the timing belt breaks. In other words, the 3L diesel bends the valves. To provide 90 l. With. and 189 Nm, the Toyota manufacturer used technical techniques:

- full counterweight crankshaft;

- the “square” nature of the motor, that is, the ratio of the piston stroke to the cylinder diameter is equal to one;

List of car models in which it was installed

The 3L engine was created exclusively for Toyota cars with severe operating conditions (off-road, heavy body, heavy-duty vehicles):

- Land Cruiser 70 – all-wheel drive all-terrain vehicle;

- Dyna – 1.5 t truck;

- Hilux Surf – all-wheel drive SUV;

- Hiace – minivan, 4th generation, H100 body;

- Hilux Pick Up – pickup, 5th generation, N80 – N130 body, all-wheel drive.

For high speeds of sedans, hatchbacks and station wagons, the engine characteristics are absolutely not suitable.

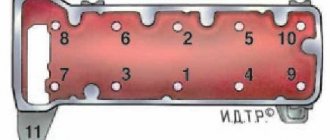

Correct tightening order

Regardless of the engine type, the procedure for tightening the cylinder head is always the same. Each head is tightened using two rows of screws running parallel to the combustion chambers. The order of the holes is from the first to the last cylinder, in the right and left row, relative to the first cylinder. Here is the correct order for tightening the screws:

- 2 central bolts of the right and left rows. In four-cylinder in-line (L4) engines they are located between cylinders 2 and 3. In L6 power units they are located in the center of cylinder 3. In V6 engines, there is a middle combustion chamber opposite each;

- 2 screws to the left of the center ones (one in each row);

- 2 to the right of the center ones (one in each row);

- 2 bolts located on the left in both rows;

- 2 bolts located on the right in both rows;

- tightening torque no more than 1 kgf.m.

Some masters prefer a different order. First, tighten the 2 central bolts (the torque is the same as described above), then the screws on the left and right along one row, and then also along the other row. Then continue to tighten the remaining bolts in the same order. Both order of tightening the head are the same in efficiency, so everyone chooses what he personally likes. The main thing is to ensure the correct force when tightening. Having tightened all the cylinder head bolts, they begin to be tightened in the same order. The moment should be 3–4 kgf.m. Then, following the same procedure, tighten again with a force of 7–8 kgf.m. The maximum torque depends on the make and model of the car, so before starting work, you should carefully read the repair instructions for your car. Otherwise, there is a high risk of damage to the cylinder head or block.

On some vehicles, you can reuse cylinder head bolts, making sure they are within the recommended length. On other machines, it is advisable to use new parts each time.

Use a torque wrench for proper tightening

If the length of the screw is longer than necessary, it will rest against the bottom of the well. Trying to tighten it will cause the bolt head to break off or strip the threads in the well. In any case, you will have to disassemble the motor, change the gasket and most likely restore the well. This will cost much more than a new set of screws.

After 300–700 kilometers (depending on the type and model of the engine), cylinder head broaching is necessary. During this run, high temperatures and vibration caused the gasket to compress, so the bolts must be retightened. Usually it is enough to turn each bolt 1-2 times by 90 degrees, focusing on the torque wrench readings, so as not to exceed the torque. The tightening procedure is the same as before.

Advantages and disadvantages

Experts consider the internal combustion engine design of the entire L series, and the 3L in particular, to be very simple. Hence the undoubted advantages of the power drive:

- there is nothing to break here, there are known cases of mileage of over 30,000 km without a pump, that is, without cooling;

- combustion chambers may burst, but do not fall out of the cylinder head, the car drives in this condition;

- the timing belt is designed for 100,000 km, often 150 thousand without replacement, although experts recommend limiting the mileage to 60 thousand to avoid collision of pistons with valves;

- there are no intermediate shafts or pushers in the gas distribution system;

- you can add mineral oil without any consequences;

- crankshaft with a full set of counterweights;

- overheating is practically impossible.

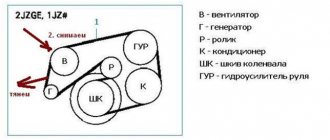

The toothed belt rotates only the camshaft (the only one) and the fuel injection pump; the rest of the mounted ones have their own V-belts, which helps to increase the service life of these consumables.

The disadvantages include strong noise during operation due to the design of the combustion chambers and pin injectors, high diesel fuel consumption and an obsolete viscous coupling. Oil starvation is possible due to the long length of the oil receiver, through which fuel and lubricants are sucked in for too long.

Engine Toyota 3L 2.8 l/91 l. With.

The 3L engine belongs to the diesel L series of the Toyota manufacturer, which has distinctive features:

- SOHC timing mechanism with pushrods;

- drive of a single camshaft by a toothed belt;

- vortex type combustion chamber;

- layout for E class cars, light commercial vehicles, heavy minivans and jeeps;

- cast iron cylinder block.

The entire series is noisy, low-power, but very reliable, for example, 3L was often used for swapping UAZs, replacing the standard power drive.

Maintenance schedule 3L 2.8 l/91 l. With.

The manufacturer's manual states that the 3L engine should be serviced at the following intervals:

- timing belt - according to the developer, 100,000 km, in practice 60 thousand;

- It is recommended to adjust the thermal clearance of the valves every 30,000 miles;

- The manufacturer provides for cleaning the crankcase ventilation every 2 years;

- the developer recommends changing the engine oil after six months or 5000 km;

- the oil filter should be replaced after 10,000 miles;

- According to the manufacturer, the air filter must be replaced after 50,000 km, cleaned twice a year (trucks and pickups), annually (buses) or monthly (commercial vehicles);

- antifreeze from the factory is enough for 40,000 km or 2 years of operation;

- the fuel filter is updated after a mileage of 60,000 km;

- the resource of spark plugs in the DIS-2 engine system is 20,000 mileage;

- The walls of the exhaust manifold begin to burn out after 60,000 km.

Valve clearances are adjusted with washers; their values are 0.25 mm and 0.3 mm (intake/exhaust, respectively).

Review of faults and methods for repairing them

In addition to the fact that at the moment of impact with the pistons when the timing belt breaks, the 3L motor bends the valve, there are other characteristic malfunctions:

| Blue smoke and oil drips on the block | reduction in compression due to wear of the cylinder liner mirror | overhaul, replacement of liners |

| Detonation and vibration | pressure valve output | pressure valve replacement |

| Doesn't start after warming up | 1) clogging of the starter 2) wear of the injection pump plunger | 1) cleaning or replacing the bearing |