A fairly common entry in the logbooks of Corolla owners... so there is no point in writing much. As is probably logical to think, the reason for the replacement was the “breaking points” in the suspension. I wouldn’t say that it rattled a lot... even while I was driving on winter tires with a high profile I almost didn’t notice it, but on summer tires with a profile of 55 it became more noticeable. I took the original bushings. I don’t see any point in saving in this case... In Exist, original bushings cost 180 rubles apiece. I was simply too lazy to go to the Existence office twice and ordered it from a store almost near my house. It came out to 500 rubles per pair. Delivered in 2 days

Issue price: 500 ₽

Toyota Corolla 2004, 97 l. With. - with your own hands

Cars for sale

Toyota Corolla, 2006

Toyota Corolla, 2005

Toyota Corolla, 2005

Toyota Corolla, 2006

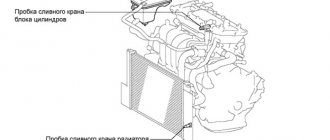

Replacing elements

You can replace worn parts yourself. At the very beginning of the repair, it is necessary to raise the car's axle. To do this, you need to tighten the handbrake and install reliable wheel chocks. The easiest way to lift the axle is with a jack, although you can also use a lift. This will position the entire suspension in balance. This procedure is required to prevent the stabilizer from pulling the entire suspension down. Otherwise, it will be impossible to install new racks. It is also important to clean the repair area, and this should be done even if there is no dirt as such.

The rear stabilizer struts are usually replaced first for convenience. First you need to grab the end of the axle shaft. To do this, you need to insert a hex key of the appropriate size. Then you need to unscrew the nut that secures the stand itself.

Purchased parts can be removed quite easily, but the factory original (if it has not been changed before) is secured quite tightly, so you need to strain a little to remove it.

The vacated space should be thoroughly cleaned. Now you can insert the new stand. However, you cannot immediately tighten the nut completely, since after returning the car to its original position from the jack, it is necessary for the part to take the correct position. This is done only at the very end of the procedure.

The front strut is a little more difficult to change. It all starts in the same way as in the case of the rear one: the axle shaft is secured, the nut is unscrewed. Next, remove the thrust washer (usually called the cup) and loosen the stem nut.

There are two bolts on the caliper mount: the top one needs to be disconnected and the bottom one needs to be loosened a little. After this, it is recommended to move the caliper a little.

Only after these procedures can you remove the bolts, having first loosened them. If the original is being replaced, it is better to release the brake hoses before disconnecting the strut. In other cases, you can do this after dismantling. Now you can insert the part and assemble it in reverse order.

see also

Comments 23

How long is the key needed and what kind please tell me?

12-socket + small ratchet

in Corollas (I myself work in Toyota), except for the front stabilizer bushings and the chain tensioner gasket, nothing breaks...the most reliable Corolla car))

yeah, if only the rack wouldn't knock))

yeah, if only the rack wouldn't knock))

over many years of work, the rack knocks on 1 car out of 500, and 4 out of 100 cars there are 5 with knocking... this is a good indicator... the Germans, yes. every 4 cars with knocking. and every third with shaft corrosion, and this after 5-6 years of operation

Well, I don’t know about 1 out of 500, but judging by this forum and many others where I communicate, it’s no secret that this is a universal disease of the 120s king and the reason for this knocking has long been known and a solution has long been found This problem is all to blame for the unfortunate plastic bushing inside the rack on the right side, which wears out very quickly due to the poor quality of the material from which it is made. This can be treated by making this bushing from fluoroplastic and replacing it. Here is one of the photo reports about this - www. vanoid.ru/netlenki/0020.html So something like this, dear levsha21. It’s very strange that you, as a Toyota employee, haven’t heard a lot about this.))

This happens very rarely, you just can’t take 100 out of 10 thousand cars where the racks are knocking and draw a conclusion about unreliability

What an eccentric man, I’m telling you, almost every owner of the 120th Corolla has encountered this problem, if you are not aware of this problem, this does not mean that it does not exist. You can create a topic in our community of owners of the 120th Corolla about this problem and you'll see for yourself.

Purpose and functions of stabilizer struts

Bushings are considered the simplest elements of a stability system. However, they quickly break down and regularly require repairs. The racks take on the entire load when stabilizing the movement. The part itself looks like a piece of pipe with hinges. It is part of a safety system that prevents roll when cornering.

The stabilizer is not connected to the suspension, but works together with it. The connecting function is performed by the stand. The load on it increases during each roll.

Therefore, the part wears out quickly. The bushing is intended for:

- combining the suspension arm and stabilizer;

- ensuring a stable position of the car when turning;

- prevent roll, maintain smooth movement.

The stand neutralizes the consequences of mistakes often made by drivers.

It prevents the car from breaking down during extreme use, such as driving on uneven roads.

What will you need?

New stabilizer bushings.

To change the stabilizer bushings on a Toyota Corolla E120, it is not at all necessary to go to a car service center. Many car enthusiasts have been carrying out the process on their own for a long time.

For a complete repair you will need a pit or a lift, as well as a set of tools.

Replacement algorithm

Before starting the procedure, it is worth noting that almost all operations will have to be done by touch, and therefore, those who are not confident in their abilities should head straight to a car service center. Let's look at the process of changing stabilizer bushings on a Toyota Corolla E120:

- We install the car so that there is full access from below. To do this, it is best to use a pit or a lift.

We find the stabilizer and bushings.

Remove the fixing protection of the stabilizer bushings.

Now unscrew the bracket and remove the bushing.

We mount a new stabilizer bushing and tighten the fasteners.

Part selection

Original stabilizer bushings.

A high-quality part is the key to successful, long and safe operation of a vehicle. That is why special attention should be paid to the choice of product.

Original

48815-12370 – original catalog number of the stabilizer bushing for Toyota Corolla with E120 body. The average cost of a product is 1000 rubles.

Analogs

Also, there are a number of analogues of the original product that can be installed on a car:

| Manufacturer's name | vendor code | Price in rubles |

| Blue Print | ADT380125 | 500 |

| Febest | TSB-ZRE151LH | 450 |

| Febest | TSB-ZZE150L | 500 |

| Febi | 42840 | 750 |

| GSP | 513153 | 300 |

| Japan Parts | RU-286 | 450 |

| Masuma | MP-1078 | 450 |

| Nippart | N4272000 | 1200 |

| Sidem | 845822 | 750 |

| Stellox | 79-00006-SX | 750 |

| SWAG | 81 94 2840 | 1000 |

| Yamato | J72058YMT | 300 |

Checking and purchasing parts

You can find out whether the stabilizer struts need to be replaced by the sound - if tapping sounds are heard in the area of one or another wheel (they can have different volumes). The sounds will be especially pronounced when driving over potholes and other “relief” roads. In addition, characteristic knocking sounds can be detected when turning, and they will be best heard from the direction in which the car is heading.

It is worth paying attention to the choice of elements. It is best to take the original, since these types of parts most successfully fit the configuration of the Toyota Corolla shock absorption system. However, the same components cannot be purchased for 120 and 150 bodies. The fact is that each new version of the car has unique parameters. This also applies to racks that differ in angle of inclination and length.

For example, on Corollas produced in 2008 and 2011, despite their chronological proximity, the dimensions of the parts are different, so it is advisable to purchase original parts for the existing car model.

conclusions

You can change the Toyota Corolla E120 stabilizer bushings yourself, but you should keep in mind that the process is quite inconvenient and may require considerable time. The choice of product should be taken carefully and seriously, since not only the performance of the suspension and its characteristics, but also safety will depend on this.

When driving over bumps, extraneous sounds may be heard from the suspension. They are created by the anti-roll bar due to damage or excessive wear on its rubber bushings.

While the car is moving, the anti-roll bar constantly changes its position when the car rolls. The load falls on the bushings, their diameter increases, and the stabilizer begins to be held less tightly. As a result, a knock appears and the vehicle's stability decreases.

The appearance of extraneous sound from the wheel arches often indicates damage to the stabilizer link. Due to the depressurization of the rubber bands, moisture gets into the gaps formed and the corrosion process starts. Bushings and racks are not repairable, so the problem with their excessive wear can only be eliminated by replacing them with new products.

A little about stabilizer struts

The part in question is located in the shock absorption system, which, in addition to struts, includes ball joints and springs. The last two components do not require frequent replacement, since their wear over long periods of operation is much lower than that of consumable components. There is a stabilizer link on each axis, so before replacing it you need to purchase at least 2 parts (it’s better to take a little more, so to speak, in reserve). It serves to compensate for translational waves that are formed when a car moves along relief sections of roads. The parts are secured using so-called lugs both on the front suspension and on the rear beam.

As you know, each part has an approximate service life.

Regarding the racks, the manufacturer assures that the original is capable of working properly for 120 thousand kilometers. However, on domestic roads the mileage ranges from 15 to 40 thousand kilometers.

Article number and approximate cost of original stabilizer bushings for Toyota Corolla 120 and their analogues

Branded bushings for Toyota Corolla 120 have article number 4881502110. The original has a price from 300 to 500 rubles.

There are products from third-party manufacturers that are not inferior in their performance characteristics and quality to branded products. The brands recommended by car owners are shown in the table below.

Table - Stabilizer bushings for Toyota Corolla 120 from third-party manufacturers

| Company manufacturer | Article number | Cost, ruble |

| Ashika | GOM2104 | 120-130 |

| Profit | 23050650 | 125-130 |

| CTR | CVT73 | 150-160 |

| Nipparts | N4232072 | 140-160 |

| Swag | 81942883 | 700-750 |

| Blue Print | ADT38050 | 800-820 |

| Febest | TSBAVF | 155-165 |

| Masuma | MP1003 | 290-310 |

| Delphi | TD1167W | 500-530 |

| Febi | 42883 | 800-840 |

| Yamato | J72060YMT | 130-145 |

| Japan Parts | RU2104 | 140-155 |

| Tenacity | ASBTO1019 | 80-95 |

| Kavo Parts | SBS9048 | 90-105 |

Useful tips for car owners

The main sign of strut wear is a knocking sound that occurs when turning. The car becomes less controllable and begins to skid. Worn elements must be replaced immediately. Both parts need to be updated, even if the second one is in good condition. This applies to both front and rear shock absorbers. If you leave the old part, it will be more difficult to drive the car. It is necessary to purchase elements of the same rigidity. Before installation, the bushing can be treated with vegetable oil. Brake fluid destroys rubber and cannot be used for treatment.