When to change the timing belt

In the technical operation manual for the Prado 150 diesel 3 liter engine, the timing belt resource is 120 thousand km. Information that it is time to change it is reflected on the dashboard (the corresponding sign is highlighted).

Replacing the timing belt on Toyota Land Cruiser Prado 150 (diesel):

To avoid the risk of breakage, the element must be changed at 100 thousand km. It is necessary to use original spare parts.

Fatal errors when replacing the timing belt

Many car enthusiasts prefer independent servicing of their car to expensive services. This way they not only save money, but also enjoy the renovation process itself. Many of them can not only do such simple operations as changing the oil, but also try to perform more serious work (for example, those related to the timing belt). Let's figure out how to prevent common mistakes.

The biggest mistake of inexperienced craftsmen is incorrectly aligned marks on the crankshaft and camshaft pulley. Not many of the home-grown auto repairmen know how they should be mutually located. Often, due to dirt in the engine compartment, these marks are simply not visible. The price of inattention can be bent valves. If an error is made in aligning the marks, then even shifting the position of the belt by a couple of teeth will lead to malfunctions in the operation of the motor, or it simply will not start.

Incorrect belt tension is the second most common mistake. Often it turns out to be overtightened and subsequently, experiencing excessive loads, breaks off. Weak tension is no less dangerous. In this case, at high speeds it can jump off or jump over the teeth. An elementary check - try turning the long free part of the belt 90° relative to its axis with your fingers. The force applied should not be excessive.

A number of particularly “frugal” motorists can only replace a time-worn belt and leave the old rollers. Usually this kind of savings backfires. If visually the old roller is still normal, then when installing a new belt, the load on it increases, and jamming may simply occur.

How to reset the timing belt replacement interval sign on a Land Cruiser Prado?

Toyota Land Cruiser Prado 150, mileage 153,000 km, belt replaced at 150 thousand. Every time after starting, the following message is displayed: “The timing belt needs to be replaced”! How to reset this service message on the Prado 150 display?

Good afternoon. When working independently to replace the timing belt on a Prado 150, 3 liter diesel, I mixed up the marks and started it. After starting, I heard not a knock, but a sort of chattering sound. Turned it off immediately. Question

Guys, thank you. But on my Pradik it’s a little different. First, all the same actions as when resetting the oil change message, only in trib B, the message “resetting data on timing belt replacement is possible” appears, release the button, the number 15 appears (i.e. the next replacement in 150,000), press again button and the long-awaited message “timing belt replacement data has been updated” appears. That's what was required. With your help and the proven “poke” method, everything worked out the second time. HOORAY.

So you want to say that the “T-Belt” indicator is displayed. It is not reset but adjustable, meaning you can re-set after what mileage the messages about the need to replace the timing belt appear.

a) Switch the display mode “ODO/TRIP” (odometer/trip computer) to “ODO” mode (located between the speedometer and tachometer, it resets the daily mileage and switches the display mode from ODO to TRIP) and turn off the ignition.

Timing belt replacement 1KD-FTV 3.0 l, 2KD-FTV 2.5 l, Toyota Diesel

Removing and installing timing belt 1KD-FTV, 2KD-FTV

. 1 - cooling system expansion tank, 2 - power steering fluid reservoir, 3 - radiator inlet hose, 4 - diffuser, 5 - fan, 6 - pulley, 7 - accessory drive belt.

Removing and installing timing belt 1KD-FTV, 2KD-FTV

. 1 — tension roller, 2 — washer, 3 — timing belt cover, 4 — timing belt, 5 — timing belt tensioner.

Timing belt 1KD-FTV, 2KD-FTV Removal

1. Drain the coolant. 2. Remove the fan diffuser. a) Unscrew the 3 bolts and remove the power steering fluid reservoir. b) Disconnect coolant bypass hoses No. 1 and No. 2 from the radiator. c) Unscrew 2 bolts and remove the expansion tank. d) Loosen the 4 fan mounting nuts. e) Remove the drive belt of the mounted units, f) Remove the 2 bolts securing the diffuser. g) Unscrew the 4 fan nuts and remove the diffuser with the fan.

3. Remove the fan pulley. 4. Remove the timing belt cover. a) (Modifications) Unscrew the bolt and remove the coolant hose clamp. b) Remove the wiring clamp. c) Unscrew the six bolts and remove the cover.

5. Remove the timing belt. a) Rotate the crankshaft clockwise until the timing marks align as shown in the figure. b) Unscrew the two bolts and remove the belt tensioner. c) Remove the timing belt.

6. Measures to prevent damage to the piston and valves. If it is necessary to slightly rotate the camshaft with the timing belt removed, turn the crankshaft back 90° to avoid collision between the piston and valves.

Installing timing belt 1KD-FTV, 2KD-FTV

1. Install the timing belt. a) Check the alignment of the alignment marks.

b) Install the timing belt. c) Using a press, slowly insert the tensioner plunger into the housing until the holes in the plunger and housing align. Caution: Squeeze the plunger while holding the tensioner in a vertical position to avoid damaging the tensioner plunger. An effort……………………………. 9.8 N d) Insert a 1.27 mm diameter pin into the hole.

e) Install the tensioner on the engine by moving the tensioner pulley towards the belt. Tighten the two mounting bolts. Tightening torque………………13 N m e) Remove the tensioner fixing rod. g) Turn the crankshaft clockwise two turns (720°) and check the alignment of the timing marks.

2. Install the timing belt cover. a) Tighten the six cover bolts. Tightening torque…………………..6 Nm b) Install the wiring holder. c) (Modifications) Install the coolant hose clamp and tighten the bolt. Tightening torque…………………18 Nm 3. Install the fan pulley. 4. Install the fan diffuser. 5. Fill with coolant 6. Make sure there are no leaks.

Tags diesel, 2KD-FTV, Toyota, 0 l, 5 l, 1KD-FTV, timing belt replacement

What is the timing belt used for and how does it work?

From the above it follows that with the help of a toothed belt, the rotation of the crankshaft and camshaft is synchronized. Some engine models still have the function of driving auxiliary mechanisms such as a pump.

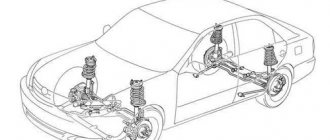

To make replacement easier, many modern internal combustion engine designers have a mechanism for gas distribution at the front or side of the engine. In the Prado diesel engine it is located between the cooling radiator and the cylinder block. Open access models are usually found on the Russian market, and to replace the Prado150 timing belt in European versions, you will need to remove the protective cover. In any case, Prado, this operation is not difficult.

Externally, the timing belt is a closed flexible rim of a certain length with an N number of teeth inside. For each motor, even of the same brand, its technical characteristics are individual. They were originally made of rubber, inside which the cord threads were made of textile material, and now they are made of special fiberglass based on special polymers that are highly durable and resistant to temperature changes.

Featured

The service life of the timing belt, declared by modern manufacturers before replacement, is at least 150 thousand km. This is confirmed by employees and service stations. The product easily takes care of such a resource, although its service life is 2 times less. However, in practice, drivers often find themselves forgetting about the replacement interval or premature belt failure due to poor quality or other negative factors.

READ Replacing the Brake Fluid Reservoir for VAZ 2109

Removing the generator of a Toyota Land Cruiser Prado

The sequence of steps is as follows:

- We remove the wheel on the right and the battery.

- We separate the positive terminal to avoid short circuiting.

- We take out the 140A fuse.

- We unfasten the plastic curtain that hides the engine section (there are 4 latches, one of them cannot be pulled out, because it will hold the parts).

- We move aside the plastic cap that closes the passage.

- Lubricate the nut with WD-40

- Take the key and unscrew the bolts (key 14). Move the tension roller to the side at the bottom.

- Remove the drive belt.

- Remove the nut (key 10).

- We separate the terminal and wire from the generator.

- Remove 2 screws from the mounting.

- Move the big bolt.

- In the direction of the wheel, remove the lower mount.

- Remove the top bolt using a long wrench.

- We separate the socket from the generator.

- While shaking, remove the generator. It is pulled out from the wheel side. If something gets in the way, just move it aside.

Generator operating principle

It doesn’t matter which car you take, all of them, including the Toyota Prado, have technical content. This includes a generator. It is very important what condition this part of the car is in, because the operation and movement of the car depends on it. Therefore, every driver should know how to remove the Prado 120 generator.

Consider the functions of a generator in a car:

- Charges the battery.

- Provides power to the vehicle.

This part wears out quite often, which is why it must be replaced. It's just a matter of time.

IMPORTANT! The generator itself notifies about problems inside with the help of characteristic noise (creaks, knocks).

Before you get a generator, you should protect yourself:

- The engine must be turned off.

- We put on a mask and gloves to protect our hands and face.

- To avoid getting an electric shock, disconnect the wire from the battery.

- We put the car on stands.

Now you need to put together the necessary tools and materials. You will need a set of ratchet wrenches, including long wrenches. A substance such as WD-40 will also come in handy.

Prado 120. Replacing the drive belt roller

It is recommended to replace the drive before it wears out or breaks. Loose pieces can damage the device and create additional problems. Overhauling a car requires a lot of money.

With the belt removed, the car owner can check the condition of the rollers. If it spins without effort, interference and unnecessary sounds, then it can be used in the future. The bearing definitely needs to be replaced when extraneous sounds (rustling, grinding) are heard during rotation.

To replace the roller you will need working tools:

- hexagon;

- spanners;

- small flat screwdriver;

- rags.

To see the 3 main elements of the transmission mechanism, you need to remove the battery terminals and remove the motor cover. After unscrewing the bolts, you need to loosen the tensioner and find the bolt that secures the drive belt wheel. Before replacement, all parts (washers, nuts, bolts) are coated with a special lubricant in order to improve their performance characteristics.

The new roller is installed in place of the worn car part in the reverse order. As a result, the part should rotate freely

It is important to ensure that the washer is on the motor side. At the next stage, the belt blade is replaced

By ignoring the replacement of drive belts in a Toyota Prado 120, the owner risks the serviceability of the entire engine. As a result of a breakdown, there may be a decrease in power and excessive overheating of the engine, excessive fuel consumption, valve deformation, and also a violation of gas distribution.

To avoid unscheduled overhauls, you should follow the advice from the Toyota owner's manual.

Installing the alternator belt

With a worn part, the car battery will not receive sufficient energy for reliable operation of the engine.

Untimely replacement leads to damage to the AKM. To install the alternator belt in a Toyota Prado 120, you may need the following parts:

- tensioner;

- belt transmission element;

- support roller;

- generator pulley;

- pulley plug;

- adjustable wrench.

The new transmission element should be tensioned in the following order:

- The furthest video.

- Tensioner.

- Bottom rollers.

- Generator.

Tighten the tensioner bolt to complete the installation. Check the degree of deflection by turning the engine 2 turns.

Time functions and design

To understand what these terms mean, you need to know how an internal combustion engine works.

The operation of any four-stroke internal combustion engine is based on cyclic phases: injection (introduction) of the air-fuel mixture, compression, ignition, combustion (expansion) and subsequent removal of exhaust gases. The gas distribution mechanism is responsible for the consistency of these processes.

The timing belt consists of a crankshaft (sometimes not just one, but several), an intake/exhaust valve and a belt (or chain). The entire system allows certain cylinders to be filled with a fuel-air mixture at a given point in the cycle, and then the exhaust gases are immediately removed into the exhaust manifold.

The valves open and close under the influence of the camshafts. They are located relative to each other in such a way as to ensure the motor phases determined by the designers.

The rotation of the camshaft is transmitted from the crankshaft through a chain or belt. An important condition for proper engine operation is compliance with the specified relative position (rotation angle) of the gas distribution mechanism relative to the CNG (cylinder-piston group). These are the so-called phases. The pulleys of the above shafts are marked, which must correspond to the specified position.

Symptoms that indicate the timing belt needs to be replaced

The rubber blade of the gas distribution mechanism ensures synchronized operation of the camshaft, crankshaft, valves and pistons. The car part is not subject to corrosion, but over time it wears out and can cause a complex breakdown.

The reliability of the timing belt in Toyota Prado 120 is determined as follows:

- Visually check the degree of sagging. To do this, remove the protective casing, rotate the crankshaft and inspect the blade along its entire length.

- Check for defects. Tears, cracks, peeling and depressions are sure to become a big problem when the engine is under heavy load.

- Traces of oil or antifreeze on the surface reduce the functionality of the gas distribution mechanism.

- Compare the mileage of the car and the service life of the part according to the technical passport.

The owner of a Toyota Prado can also determine damage to the timing mechanism for such indirect reasons as:

- the engine stalls for no reason;

- exhaust gas turned black;

- extraneous sounds are heard and uncharacteristic vibration is felt from under the hood;

- the car starts with difficulty, jerking and loss of power;

When does the alternator belt need to be replaced?

Before installing a new alternator belt, you should make sure that the mechanism is faulty. The first sign of a loose belt is a characteristic whistle in the engine when there is a load on the electrics (headlights, air conditioning) at idle speed.

The degree of wear can be visually determined by the following signs:

- fiber detachment;

- cracks;

- damaged rib elements.

Use your hand to check the position of the part relative to the groove at the bottom of the pulley.

If there are no obvious breaks, cracks or oil on the surface, try tension with your thumb. If, with a force of 10 kg, the blade bends by more than 5 mm, then it is necessary to tighten the alternator belt on the Prado 120.

Causes and consequences of Prado timing belt rupture

That being said, timing belt rupture on a Prado does happen, and often. The main factors that cause this emergency are:

According to experienced car service workers, the most common is the destruction of the Prado gas distribution mechanism due to its natural aging. Often, Russian motorists drive up to 50 thousand km during the recommended replacement period. Until the belt simply bursts due to old age. In this case, it needs to be replaced and the fault lies solely with the driver of the Prado due to negligence.

The second most common cause of drive failure in a Prado is a problem with the pulleys and/or tensioners, as well as a seized water pump on very old engines, which, as mentioned earlier, can also be torqued. It is recommended to check the condition of these mechanisms and the degree of tension of the belt itself, and if necessary, replace it during scheduled maintenance.

If a technical inspection of the Prado belt reveals the presence of aggressive technical fluid or automobile oil, it should be replaced as soon as possible.

Finally, by installing products from little-known manufacturers in your car, you increase the risk that the belt will not be declared at 60,000 km. And due to the dire consequences of interruption for Prado diesel engines, we do not recommend saving on this relatively inexpensive consumable, in case of replacement, by purchasing quality products.

The picture of Prado clutch belt is as follows. The camshaft rotates, the valves stop, and this may be their open position. Since there are no valve recesses on the surface of the Prado150 3.0 diesel engine pistons, they may encounter open valves. As a result, in the best case, you get a Prado engine that has just stopped; in the worst case, you get bent valves, their guides and even deformation of the piston mirror. All this will require expensive repairs and replacement.

What's more, the chain can damage the camshaft lobes and, in particularly unfortunate cases, damage the Prado's cylinder head or crank mechanism. Therefore, measure the cost of a quality belt with its replacement and the cost of likely repairs if it breaks.