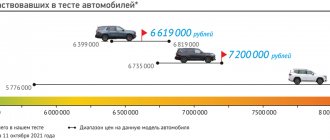

Remove the gearbox (see subsection 12.2.).

Note 1

When removing the clutch housing mounting bolts, block the flywheel using a screwdriver. Install a bolt to stop the screwdriver.

Note 2

You can remove the clutch without a mandrel, but you must hold the driven disk - it may fall out of the clutch housing. The mandrel can be made to fit the input shaft, or you can use an old input shaft instead.

Flywheel friction working surface.

1. Insert the mandrel into the pressure plate hole and remove the six bolts securing the clutch housing to the flywheel (see notes 1 and 2).

2. Carefully remove the clutch cover from the driven disc.

3. Inspect the driven disk. There should be no cracks on the driven disk parts. Check the wear of the friction linings. Replace the friction linings or the driven disk in the following cases: a) the rivet heads are recessed to a distance of less than 0.2 mm; b) the surface of the friction linings is oily; c) rivet joints are loose.

4. Check the reliability of the damper springs in the driven disk hub sockets. If the springs are broken, the disc must be replaced. If warping of the disk is detected during a visual inspection, check its runout. If the runout value exceeds 0.5 mm, replace the disc.

5. Inspect the working friction surfaces of the flywheel and pressure plate: they should not have deep marks, scuffs, nicks, obvious signs of wear and overheating. It is unacceptable to loosen the rivet connections of the pressure plate parts. If defects are found on the flywheel or pressure plate, we recommend replacing them.

6. Carefully inspect and evaluate the condition of the support rings and the pressure plate diaphragm spring. The support rings must not have cracks or signs of wear. Cracks on the diaphragm spring are unacceptable. The contact points between the spring petals and the clutch release bearing must be in the same plane and have no obvious signs of wear.

7. Install the driven disk into the pressure plate housing so that the less protruding part of the hub is directed towards the flywheel.

8. Insert the centering mandrel into the splines of the driven disk from the diaphragm spring side.

9. Install the clutch on the flywheel and tighten the six bolts securing the clutch to the flywheel evenly diagonally to a torque of 19-31 Nm (1.9-3.1 kgfm). After this, remove the centering mandrel.

Replacing the clutch on a 1st generation RAV4

To remove the box in a car up to a year old, you should tilt its left edge.

Remove the bolts holding the old basket in place. In this case, use a special device - a guide shaft of the appropriate diameter, which will be required later for centering the clutch disc when installing a new unit

When dismantling, pay attention to which side the clutch disc is installed, so as not to confuse the position when assembling a new unit

We signed up for a service, since the replacement seemed like a bad idea at first glance, but the forums and repair manual still told us to do it ourselves. Overpass on the street, in a closed area.

Toyota Rav4 clutch from 2013

Everything is logical and understandable in principle, we disconnect everything that gets in the way, the four-wheel drive cardan, the subframe, the starter, I didn’t remove the traction

It is very important to place some kind of stick behind the intake manifold, otherwise the engine will fall BACK from behind the transfer case shank and there is a possibility of breaking all the tubes located on the engine shield

Toyota Rav 4 clutch replacement on the ground. I wanted to unscrew only the box without the transfer case, but it sat so well on the sealant and it was decided to unscrew the whole thing.

The box is separated from the engine with a Toyota Rav 4 clutch replacement, not straight and straight, but at a slight angle. There were no particular difficulties... if only the floor was made of thick rubber and the work being carried out in one... it was all very heavy, a 3 meter long pipe was used, and automotive fittings were used for the lever.

12.15. Clutch replacement

| GENERAL INFORMATION |

| Disassembled clutch: 1 — pressure plate |

Remove the gearbox (see subsection 12.2.).

Note 1

When removing the clutch housing mounting bolts, block the flywheel using a screwdriver. Install a bolt to stop the screwdriver.

Note 2

You can remove the clutch without a mandrel, but you must hold the driven disk - it may fall out of the clutch housing. The mandrel can be made to fit the input shaft, or you can use an old input shaft instead.

| Flywheel friction working surface. |

| EXECUTION ORDER |

Signs you need to replace your clutch

The first signs of a malfunction may be a suspicious noise when the clutch is engaged, a specific smell indicating that it is not completely disengaged

You should also pay special attention when, when you engage a higher gear, the car begins to slip.

This sometimes happens in cars that have already had a long service life (clutch life is approximately 150-200 thousand km). And also when you abruptly engage (disengage) the clutch or constantly (long) hold the pedal.

Before deciding to replace the clutch assembly or its elements, you should make sure that this unit is faulty. So make sure that:

- there are no leaks of hydraulic fluid in the area of the working cylinder;

- the brake fluid level is constant and corresponds to that prescribed by the manufacturer;

- the working cylinder is in good condition;

- There is no engine oil leakage caused by wear of the crankshaft rear oil seal.

Clutch. Basic information

"https://www.w3.org/TR/xhtml1/DTD/xhtml1-transitional.dtd">

Clutch. Basic information Toyota RAV 4 Toyota RAV4

| Site search |

| + Operation + Tech. maintenance + Engines + Air conditioning and cooling + Fuel system + Ignition + Emission control system - Clutch - Basic information - Tech. characteristics - Clutch master cylinder - Clutch slave cylinder - Hydraulic drive bleed - Clutch driven disc - Clutch release bearing - Clutch switch + Gearbox + Drive shaft and drive wheel shafts + Brakes and components + Suspension + Steering wheel and chassis + Body and its components + Electrical equipment + Electrical equipment diagrams |

| Figure - 8.1. Clutch: 1 – flywheel; 2 – clutch disc; 3 – pressure disk; 4 – clutch release bearing; 5 – fixing spring; 6 – clutch release fork; 7 – stud with ball pin; 8 – protective cover |

All models are equipped with a dry single-plate clutch, which consists of a driven and pressure plate, a central diaphragm spring, a casing and a clutch release bearing (see figure - 8.1). The driven clutch moves freely on the splines of the input shaft of the gearbox and is clamped between the flywheel and the pressure plate the force created by the central diaphragm spring. Friction linings are riveted on both sides of the driven disk. The driven clutch disc is connected to the hub through the torsional vibration damper parts. The need for a torsional vibration damper is caused by the following. When there is a sudden change in vehicle speed, hitting uneven roads, abruptly engaging the clutch, as well as due to uneven engine operation, dynamic loads arise in the vehicle transmission, causing twisting (unwinding) of the transmission shafts. Uneven engine torque can cause significant overloads in the transmission due to the occurrence of torsional vibrations and resonance when the frequencies of the transmitted loads coincide with the natural frequencies of the transmission. Elastic vibrations of the transmission lead not only to noise in mechanisms and assemblies, but also to dangerous vibrations, and sometimes to breakdowns of parts when the vibration amplitude reaches a large value. A damper is needed to absorb the energy of torsional vibrations. The clutch release drive is hydraulic. The clutch release bearing is mounted on the front side of the transmission on the clutch release clutch. The bearing is mixed by the clutch release fork. When you press the clutch pedal, the piston in the master cylinder moves and compresses the fluid, which flows through a hose into the clutch slave cylinder. Under pressure, the piston of the clutch slave cylinder moves and actuates the clutch release fork. The clutch release fork moves a bearing that acts on the pressure plate spring and moves the pressure plate away from the clutch driven plate. The clutch adjusts automatically. Before replacing components that have clearly failed, perform the following preliminary checks to diagnose clutch and clutch actuator failure: Check the brake fluid level in the brake system reservoir, which also serves as the reservoir for the hydraulic clutch actuator. If the level is below the required level, add fluid and check the hydraulic system for brake fluid leaks. With the engine idling and the gearshift lever in neutral, press the clutch pedal and after a few seconds engage any gear without any noise being heard from the gearbox. If there is increased noise when engaging the gear, the pressure plate and/or clutch disc may be defective. To check that the clutch is completely disengaged, start the engine, apply the hand (parking) brake, press the clutch pedal so that it does not reach the floor by 10–15 mm, and engage and disengage first gear several times. If the gear is difficult to engage, check the stroke of the clutch master cylinder pusher and the fluid level in the brake system reservoir. Visually Check the clutch pedal bushing, located at the top of the pedal, for excessive play or binding. From below the car Check that the clutch release fork is installed on the stud with the ball pin.

| The manual is intended for Toyota RAV4 vehicles | Privacy Policy |

Toyota RAV4 clutch replacement (Rav 4) in Moscow

Activities to replace the Toyota RAV4 (Rav 4) clutch will be carried out by the masters of our network of car service centers “Tokyo Service”. The workshops have created optimal technical conditions for performing free diagnostics and repairs of any complexity. All parts necessary to replace a faulty clutch are available in our own warehouse.

Clients of the workshop network have access to:

- discounts of up to 40% from the prices indicated by the official dealer;

- maintaining the factory warranty;

- selection of components in accordance with the make and model of the car.

To sign up for any of our network of service centers, leave a request on the website or call.

Spare parts for repairing Toyota RAV4 manual transmission

Almost all spare parts for the Toyota RAV4 transmission are in the company’s warehouse. This means that when the car arrives, we will immediately select parts for it and begin repairs. This approach significantly reduces the time of repair work.

Moreover, we offer a choice of components of different classes, including:

- original car parts;

- analog auto parts;

- new parts;

- refurbished, used components.

Original spare parts are ideally compatible with all car mechanisms and are more durable. But if the car owner is not satisfied with the price, he can choose less expensive substitutes. Moreover, we offer only high-quality analogues from well-known companies. We select by VIN number and article number.

Toyota Rav-4: weak points. Maintenance and repair

Taking the best from a powerful SUV and an economical passenger car, the Toyota Rav-4 cannot but please its owners.

This SUV is famous for its rich equipment and reliability, efficiency and modern technologies, but, like any other car, it needs high-quality technical maintenance, and over time, repairs.

The Rav-4 is primarily intended for city driving, and it shows its true character both in winter and during trips into nature. Don’t forget that even though the car is a crossover, it is not suitable for regular off-road “testing” unless you are prepared for constant breakdowns and expensive repairs.

Maintenance

Rav-4 owners are recommended to check the level of the vehicle's operating fluids (engine oil, coolant and brake fluid, etc.) every 400 km.

Before doing this, you should make sure that the machine is standing on a flat, horizontal surface, otherwise it will be impossible to obtain reliable readings. After such a run, the integrity of the tires, their pressure, and tread wear are also checked.

Every mileage exceeding 5,000 km is a signal that it’s time to change the engine oil and oil filter in your Rav-4.

Regular maintenance of your Rav-4, both weekly preventative maintenance and at a service center, should become a habit. This is a guarantee of your safety, and your Toyota will stay on the road longer.

weak spots

Toyota Rav-4 is a car with great capabilities, but it also has its weak points. The most problematic is the first generation of machines. After 100 - 150 thousand kilometers, they begin to have problems associated with oil seals, fuel tank, coolant pump, gearbox mount, etc.

Second-generation crossovers are very sensitive to consumables. If you refuel the Rav-4 with low-grade fuel, be prepared to regularly clean the injectors every 20 thousand km. After 50-60 thousand

kilometers, the oxygen sensor and ignition coil may fail. There are frequent problems in cars with automatic transmissions, the electronic components of which can fail after 150 thousand km.

At the same time, problems may appear in the clutch system.

The third generation of Rav-4 is much more reliable than its predecessors. However, replacing the front suspension bushings may become necessary after 50 thousand km, and the suspension itself will most likely have to be thoroughly repaired even before your Rav-4 reaches the 150 thousand km mark.

Rav-4 owners who carefully operate their vehicle and do not neglect maintenance should not worry that their Toyota will quickly break down. This durable machine does not give up easily, and, despite some shortcomings that are characteristic of all machines, it will serve you faithfully for many years.

Summing up

In general, these cars have proven themselves well and, with proper care, last a long time and are inexpensive. However, this is not a real jeep and off-roading is not its strong point. It also won’t show any sporting qualities on the highway or at traffic lights. This budget option is very good for everyday driving and for solving everyday problems.

Payment via PayPal

After selecting payment via PayPal, the PayPal payment system will launch, where you need to select the payment method: bank card or PayPal account.

If you already have a PayPal account, then you need to log into it and make a payment.

If you do not have a PayPal account and you want to pay using a bank card via PayPal, you need to click on the “Create an Account” button - shown with an arrow in the picture.

PayPal will then prompt you to select your country and provide your credit card information.

After specifying the information required to make the payment, you must click on the “Pay Now” button.

Problems when paying with bank cards

Sometimes difficulties may arise when paying with Visa/MasterCard bank cards. The most common of them:

- There is a restriction on the card for paying for online purchases

- A plastic card is not intended for making payments online.

- The plastic card is not activated for making payments online.

- There are not enough funds on the plastic card.

In order to solve these problems, you need to call or write to the technical support of the bank where you are served. Bank specialists will help you resolve them and make payments.

That's basically it. The entire process of paying for a book in PDF format on car repair on our website takes 1-2 minutes.

If you still have any questions, you can ask them using the feedback form, or write us an email at

Toyota RAV4 success story

Toyota RAV4 was developed by a Japanese company at the end of the 20th century. To date, four generations and three restylings of the car have been produced. Since 2013, a modern modification has appeared on the domestic market. The five-door Toyota RAV4 is equipped with a 2.5 liter petrol engine. and a power of 180 hp, which is combined with a 6-speed automatic transmission and all-wheel drive. Created for active recreation, the car has the highest levels of functionality, cross-country ability, and spaciousness. Eight trim levels provide the motorist with a wide choice.

Why should car repairs be carried out in our car service center?

It is worth noting that our cars are truly serviced by specialists in their field. Our employees have extensive experience and do not stop learning for a minute. Also, we have high-quality equipment. Finally, we are always happy to help you, our valued clients and customers!

Completely confident in the quality of the repair work carried out, we provide a guarantee on repairs and spare parts of 1 year! Come visit us and make sure that our RS service does not make false claims.

Installation procedure

In order for the new clutch to operate for a long time, it may be necessary to replace the release bearing along with the clutch disc (ferredo), as well as install a new basket (if there was significant overheating) and fork. However, the need to replace each element can be accurately determined only after dismantling.

All Toyota Rav4 cars with manual transmission are equipped with a single-plate dry clutch. Immediately before disassembly, it is necessary to install the front part of the car on supports. Place wheel chocks under the rear wheels and block the hand brake cable. You should also remove the battery together with the support.

- Remove the hood along with the ventilation chamber casing.

- Remove the front wheels and drive shafts.

- Remove the air filter base along with it.

- Drain the coolant and oil inside the gearbox and engine.

- Disconnect the coolant lines, fuel lines, electrical connectors, including those that go to the ECU.

It is permissible not to remove the fan shroud, fan and radiator. But in this case, it is necessary to disconnect the transmission oil cooler pipelines from it.

Remove the generator, as well as the starter, after first disconnecting the electrical wiring that goes with them.

On a car with an installed air conditioning system, it is necessary to unscrew the bolts securing the air conditioning compressor. Hang the knot and secure it by moving it to the side.

Disconnect the transmission control rods. If a manual transmission is installed, remove the working cylinder. There is no need to open the air conditioner circuit.

Remove the driveshaft.

On models built before 2001, the power steering pump must be removed.

Remove the exhaust pipe from the exhaust manifold. Remove the elastic beams holding the gearbox. Unscrew the bolts securing the box to the engine (their location must be marked, since they must be installed in their places during assembly).

To remove the box in a car before 2001, you should tilt its left edge.

Remove the bolts holding the old basket in place.

In this case, use a special device - a guide shaft of the appropriate diameter, which will be required later for centering the clutch disc when installing a new unit.

When dismantling, pay attention to which side the clutch disc is mounted so as not to confuse the position when assembling a new unit. Replacing the clutch on a Rav 4 is recommended with the obligatory installation of a new release bearing

If necessary, clean the inside of the box from clutch residues, and be sure to degrease the surface of the plates and flywheel. This will prevent slippage when connecting the disc to the flywheel.

Replacing a Toyota Rav4 clutch does not require much time, unlike a large number of preparatory activities and disassembly and reassembly of related components.

Installation should be carried out in reverse order. All bolt tightening torques must comply with the manufacturer's recommendations.

If necessary, an oil change can be timed to coincide with clutch replacement. And also replace CV joint boots, brake pads, other consumable components and carry out maintenance of other vehicle elements.

If the material was interesting or useful for you, publish it on your social network page:

Source

Clutch mechanism

Removal

1. Remove the manual transmission assembly.

2. Remove the clutch release fork along with the release bearing.

3. Remove the release bearing from the clutch release fork.

4. Remove the clutch release fork support from the transmission.

5. Remove the clutch release fork cover from the transmission housing.

6. Remove the clutch cover assembly:

- Align the assembly marks of the clutch housing and flywheel.

- Loosen all installation bolts by turning them 180° in one operation until the spring tension is released.

Note

:

Loosen the bolts evenly in the sequence shown in the figure, turning them 180° in one operation.

Unscrew the installation bolts and remove the clutch cover.

Note

:

Be careful not to drop the clutch disc.

Downloading a book

After successfully completing the payment (by any method) and returning to the KrutilVertel store from the payment system website, you will be taken to the successful payment page:

The book you purchased will be in your personal account, from where you can always download it.

Please note that after making the payment, you need to return back from the payment system website to the KrutilVertel website. If for some reason you did not return back to the site and closed the payment system tab with a message about the successful completion of the payment, please let us know - we will send you a letter indicating access to download the book

If for some reason you did not return back to the site and closed the payment system tab with a message about the successful completion of the payment, please let us know - we will send you a letter indicating access to download the book.

Symptoms of a CVT malfunction on a RAV 4

The Toyota RAV-4 variator is sensitive to the quality and condition of the oil. Therefore, the oil needs to be changed regularly, observing intervals. In addition, you need to buy only original fluid for the Toyota RAV-4 variator.

When replacing the transmission fluid, the filter element is also changed. If this is not done, the oil pressure will begin to drop, which will lead to increased wear of the variator elements.

Shaft bearings begin to break down at 70–80 thousand km, if the motorist practices an active driving style. The bearings need to be replaced, as they will wear out even faster in this mode.

As soon as you notice any changes in the operation of the box, do a CVT diagnostic. Let's look at the characteristic signs of a malfunction, by which you can determine that a breakdown will soon occur and replacement or repair of RAV 4 parts will be required:

- the car starts to slip;

- The automatic transmission emergency mode icon appears on the gear panel;

- there is constant or occasional vibration (check the pillows);

- when you change gear (any), you notice jerking (both with a hot and cold engine);

- transmission disappears;

- shocks (“kicks”) are observed in the transmission system;

- the presence of other problems: noise, the variator begins to slow down, “stupid”.

It is necessary to undergo timely maintenance of the Toyota RAV-4 variator (at least change the oil and filters). If the situation gets worse, the valve body and variator need to be flushed. You need to regularly check the oil level in the gearbox with a dipstick. Take your time in winter, warm up the engine or drive a short distance at low speed.

Possible breakdowns of a manual transmission

Main breakdowns of the RAV4 manual transmission:

- Increased operating noise caused by a drop in oil level. It is necessary to drain the remaining fluid and make sure that there are no metal shavings in the fluid that form when gears or bearings are destroyed. After filling with fresh oil, the extraneous noise should disappear.

- Oil leaks through damaged oil seals; repair consists of installing new seals and adding lubricant to the required level.

- Reverse lights not working, the problem occurs when the limit switch is broken or the wiring harness is broken. It is necessary to install a new contact mechanism or restore the integrity of the cable.

- Difficulty switching due to improper adjustment of the rocker drive or damage to the synchronizers. The repair consists of adjusting the length of the cables or rebuilding the manual transmission and replacing worn elements. At the same time, you should check the condition of the clutch disc, which quickly wears out if used carelessly.

- Spontaneous shutdown of the overdrive due to wear of the clutch, gear or hub. To restore functionality, you will need to disassemble the box and replace damaged parts. When the synchronizer wears out, the shift lever wobbles, which occurs when accelerating or releasing the throttle. Further wear of the ring leads to spontaneous shutdown of the speed.

- Gradually unscrew the screws securing the plate holding the bearings in the housing. As a result, the overdrive gear and part of the secondary shaft are destroyed, and cases of crankcase rupture have been reported. It is necessary to remove the box for disassembly and troubleshooting, followed by a major overhaul.

Many owners of cars with manual transmission note a quiet, uniform hum when driving in reverse gear.

The reason is the profile of the gears and the large gear ratio. Noise is not a sign of malfunction as long as there are no abnormal sounds when using forward speeds. On cars with a 6-speed transmission, a howling noise is often observed when driving in the 1st stage. An extraneous hum is not considered a malfunction provided that other speeds are operating normally and there are no chips in the oil.