Date: 03/07/2015

Each technical component in a car has its own specific service life - the length of which depends primarily on the degree of load applied to it. As we all know, components such as suspension and support systems are subject to special stress. However, special attention should be paid to the steering column of the car. Constant turns of the steering wheel make this unit one of the most vulnerable in the entire car. When this unit wears out, a knocking sound appears in the steering column, which at first becomes annoying while driving, and then begins to significantly irritate and cause particular inconvenience.

It is very important to eliminate it, since in a neglected state the column can jam while driving. This is very undesirable, since you can harm your health - if you get into an accident, as well as the car itself - for the same reason. In this article we will talk about what breaks in it, and we will also help in eliminating the knocking of the steering column on a Toyota Corolla.

Solved - Toyota Corolla. EUR. Knock in the steering column. | Car owner forums

12/23/2019 Corolla

There's a lot to think about. Based on the recommendation of forum member znayko drive2.

Dismantling the intermediate steering shaft Toyota Corolla

Well, let's start: Quote from the site » venzaclub. It absorbs vibrations and shocks, thereby protecting the bearing from destruction. It is very easy to treat, above the brake pedal on the column there is a plug with a screwdriver and with light blows of a hammer we pick out the plug, under it we see a bearing, and around it this very bushing is shaped like an open ring and at the ends of the lock there are whiskers that create tension in this unit, we pull it out with suitable tools the bushing towards you is the intermediate steering shaft of a Toyota Corolla 2008, then we take platypus-type pliers and carefully bend the mustache from its root in the direction of the ring by about degrees, then we take this bushing and put it in place, observing its original position and fill the mustache with the intermediate steering shaft Toyota Corolla 2008, putting a special groove in place while maintaining the springiness of the bushing is much more difficult than removing it, so be patient and use a set of strong expressions. When you finish the work upside down, use a hammer to carefully hammer the plug into place.

And a little from. Under the steering wheel, remove the instrument panel trim 2.

We climb under the steering wheel and see the plug. Using a hammer on the intermediate steering shaft Toyota Corolla 2008, we unscrew the plug with a screwdriver, under it we see a bearing, and around it this very bushing is shaped like an open ring and at the ends of the lock there are whiskers that create tension in this unit. We remove this plug. Using suitable tools, pull out the bushing. Plug, spring bushing before modification, rubber gasket EUR worm shaft with bearing without spring bushing.

Toyota Corolla Forum

This was not enough for me, I pulled the bushing back and saw that the “whiskers” of the spring bushing had returned to their original position. Then I decided to tighten these “whiskers” with a spring.

Then I inserted a screwdriver into the groove and, shaking the steering wheel, pressed the bearing. The knocking noise when rocking the steering wheel has disappeared. I tightened the bearing with a screwdriver. Then I decided to tighten the “whiskers” of the bushing with a rubber band, bought a Toyota Corolla 2008 intermediate steering shaft at the nearest auto store, a tube of suitable thickness, cut out a small piece and inserted the Toyota Corolla 2008 intermediate steering shaft into the groove with some effort. It is very easy to treat, above the brake pedal on the column there is a plug with a screwdriver and with light blows of a hammer we pick out the plug, under it we see a bearing, and around it this very bushing is shaped like an open ring and at the ends of the lock there are whiskers that create tension in this unit, we pull it out with suitable tools the bushing towards you is easy, then we take platypus-type pliers and carefully bend the mustache from its root in the direction of the ring by about degrees, then we take this bushing and put it in place, respecting its original position and tuck the mustache into a special groove and put it in place, maintaining its springiness The bushings are much more difficult than removing it, so be patient and use a set of strong expressions. When you finish the work upside down, use a hammer to carefully hammer the plug into place.

This is interesting: Checking the electric lock of the front door on the passenger side

Diagnostics of the electrical circuit

When diagnosing the electrical circuit of a Toyota Corolla, it is important to perform the following steps:

- Check if circuit breakers are installed, as well as fuses, this will allow you to draw conclusions regarding their performance.

- Check the charge level of the Toyota Corolla battery and the reliability of the wire connections of this unit. It is important that the connections are clean, free of deposits, salts and oxides.

- An obligatory step in diagnosing the circuit is checking the contacts, which must certainly not have any violations of the connected elements. In the event that there is contamination, peeling, or damage to integrity, the contacts are repaired - stripped.

- The process of disconnecting the connector for connecting the terminals will require quite a lot of attention; it is important not to pull the wires, but to use only the body of the connector itself for these purposes. This will eliminate damage to individual contacts of the circuit, making repairs economical, without additional operating costs.

Steering wheel for Toyota Corolla

Under the steering wheel, remove the instrument panel trim 2. We climb under the steering wheel and see the plug.

Using a hammer and a screwdriver, we unscrew the plug, under it we see a bearing, and around it this very bushing is shaped like an open ring and at the ends of the lock there are whiskers that create tension in this unit. We remove this plug. Using suitable tools, pull out the bushing.

Plug, spring bushing before modification, rubber gasket EUR worm shaft with bearing without spring bushing. This was not enough for me, I pulled the bushing back and saw that the “whiskers” of the spring bushing had returned to their original position. Then I decided to tighten these “whiskers” with a spring.

Then I inserted a screwdriver into the groove and, shaking the steering wheel, pressed the bearing. The knocking noise when rocking the steering wheel has disappeared.

I tightened the bearing with a screwdriver. Then I decided to tighten the “whiskers” of the bushing with a rubber band, bought a tube of suitable thickness from the nearest auto store, cut out a small piece and inserted it into the groove with some effort. I hammered the plug into place and drove home joyfully.

I didn’t even turn on the music, I listened to silence. And then bang “blink”.

Previously, at any speed, even crawling along a ridge, knocking noises were heard, but now only at high speed and impressive unevenness, once it rattles.

Tags:

2008 shaftcorollaintermediatesteering toyota

Removing the steering wheel assembly

Rice. 5.22. Unscrewing the steering wheel nut

Unscrew the steering wheel mounting nut (Fig. 5.22).

Note the relative position of the steering wheel and steering shaft.

Using SST, remove the steering wheel assembly.

Remove the lower part No. 1 of the instrument panel.

Remove the No. 1 leg airbag assembly.

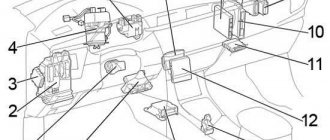

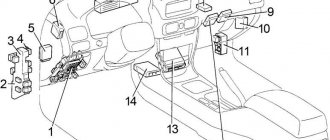

Blocks under the hood

Block layout

Decoding

- Glow plug relay

- Fuse and relay box

- Generator control unit

- Glow plug control unit

- Cooling fan control unit

- Injector control unit

- Headlight wiper relay

- The engine control unit

- Brake control module (MMT)

- Relay block (LHD)

- Brake control unit

- Relay Block (RHD)

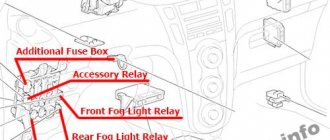

Fuse and relay box

Option 1

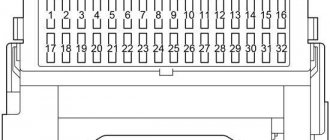

Scheme

Description

| 1 | 10A ECU-B NO.2 - Air conditioning, window lifts, intelligent entry and start system, mirrors, instrument cluster |

| 2 | 5A ECU-B NO.3 - Electric power steering |

| 3 | 7.5A AM2 - Multiport fuel injection system/sequential multiport fuel injection system, starting system, fuse: “IG2” |

| 4 | 30A D/C CUT - Fuses: “DOME”, “ECU-B NO.1”, “RADIO” |

| 5 | 10A HORN - Horn |

| 6 | 20/25/30A EFI-MAIN – Multiport fuel injection system/sequential multiport fuel injection system, fuses: “EFI NO.1”, “EFI NO.2”, fuel pump |

| 7 | 5A ICS/ALT-S - Charging system |

| 8 | 10A ETCS - 1ZR-FAE, 1NR-FE, 1ZR-FE, 2ZR-FE, 8NR-FTS: Throttle valve |

| 20A EDU - 1AD-FTV: Multiport fuel injection system/sequential multiport fuel injection system | |

| 9 | 10A TURN & HAZ - Except 8NR-FTS: Instrument Cluster, Turn Signals |

| 30A ST - 8NR-FTS: Starting system | |

| 10 | 15A IG2 - Instrument cluster, multiport fuel injection system/sequential multiport fuel injection system, airbags |

| 11 | 20A EFI-MAIN NO.2 - 1AD-FTV: Multiport fuel injection system / sequential multiport fuel injection system |

| 15A INJ/EFI-B - Gasoline: Multiport fuel injection system/sequential multiport fuel injection system | |

| 10A ECU-B NO.4 - 1ND-TV, (Sedan (1AD-FTV): Multiport fuel injection system/sequential multiport fuel injection system | |

| 20A ECU-B NO.4 - 8NR-FTS: Multiport fuel injection system/sequential multiport fuel injection system | |

| 7.5A DCM/ MAYDAY - 1NR-FE (from April 2016): Telematics system | |

| 12 | 30A EFI-MAIN NO.2 - Except 8NR-FTS: Multiport fuel injection system/sequential multiport fuel injection system |

| 7.5A DCM/ MAYDAY - Sedan (1ZR-FE, 1ZR-FAE, 2ZR-FE): Telematics system | |

| 10A EFI-MAIN NO.2 - Sedan (1ND-TV): Multiport fuel injection system/sequential multiport fuel injection system | |

| 13 | 30A ST - Except 8NR-FTS: Starting system |

| 10A TURN & HAZ - 8NR-FTS: Instrument cluster, direction indicators | |

| 14 | 30/40A H-LP MAIN - “H-LP RH-LO”, “H-LP LH-LO”, “H-LP RH-HI”, “H-LP LH-HI” - Headlights |

| 15 | 30A VLVMATIC - Multiport fuel injection system/sequential multiport fuel injection system |

| 16 | 80A EPS - Electric power steering |

| 17 | 10A ECU-B NO.1 - Wireless Control System, Body Electrical Control Unit, VSC, Intelligent Entry and Start System, Clock |

| 18 | 7.5A DOME - Interior lighting, individual mirror lighting, luggage compartment lighting, body electrical control unit |

| 19 | 20A RADIO - Audio system |

| 20 | 10A DRL - Daytime running lights |

| 21 | 15A STRG HTR — Heated steering wheel |

| 22 | 30A ABS NO.2 - ABS, VSC |

| 23 | 40A RDI - Cooling fan |

| 24 | — |

| 25 | 30/50A DEF — Heated rear window, heated mirrors |

| 26 | 50A ABS NO.1 - ABS, VSC |

| 27 | 50A HTR – Air conditioning |

| 28 | 120/140A ALT - Charging system |

| 29 | 10A EFI NO.2 - Multiport fuel injection system/sequential multiport fuel injection system |

| 30 | 10/15A EFI NO.1 - Multiport fuel injection system/sequential multiport fuel injection system |

| 31 | 10/20A EFI-NO.3 - Multiport fuel injection system/sequential multiport fuel injection system |

| 32 | 10A MIR-HTR — Multiport fuel injection system/sequential multiport fuel injection system, heated mirrors |

| 33 | 10/15A H-LP RH-LO - Low right beam |

| 34 | 10/15A H-LP LH-LO - Low left beam |

| 35 | 7.5/10A H-LP RH-HI - High right beam |

| 36 | 7.5/10A H-LP LH-HI - High left beam, instrument cluster |

| 37 | 15/20A EFI NO.4 - Multiport fuel injection system/sequential multiport fuel injection system |

| 38 | — |

| 39 | — |

| 40 | — |

| 41 | 15A AMP - Audio system |

| 42 | — |

| 43 | 20A EFI-MAIN NO.2 - Multiport fuel injection system/sequential multiport fuel injection system |

| 44 | 20A STRG LOCK - Steering wheel lock |

| 45 | 50A AMT - Transmission control unit |

| 46 | 40A BBC - Start-stop system |

| 50A AMT - Transmission control unit | |

| 47 | 80A GLOW — Preheating system, spark plugs |

| 48 | 30A PTC HTR NO.2 - Auxiliary heater |

| 49 | 30A PTC HTR NO.1 - Auxiliary heater |

| 50 | 30A H-LP CLN – Headlight cleaners |

| 51 | 30A ABS NO.1 - ABS, VSC |

| 52 | 30A CDS FAN - Cooling system fan |

| 53 | 30A PTC HTR NO.3 - Auxiliary heater |

| 54 | — |

| 55 | 10A S-HORN - Anti-theft system |

| 56 | 25A STV HTR - Auxiliary heater |

| 20A DEICER - (1ZR-FE, 1ZR-FAE, 2ZR-FE, 1NR-FE): Heating of brush rest area | |

| A | |

| 57 | 10A EFI NO.5 - 1ND-TV (from May 2015): Multiport fuel injection system/sequential multiport fuel injection system |

| 58 | — |

| B | |

| 57 | 15A EFI NO.6 - 1ND-TV (from May 2015): Multiport fuel injection system/sequential multiport fuel injection system |

| 58 | 15A EFI NO.7 - 1ND-TV (from May 2015): Multiport fuel injection system/sequential multiport fuel injection system |

Relay

| R1 | Electric Power Steering (EPS) |

| R2 | Injectors (INJ) |

| Sedan (1ND-TV (from April 2016): Engine control unit (EFI-MAIN NO.2) | |

| R3 | Starter (ST NO.1) |

| R4 | Daytime running lights (DRL) |

| R5 | Horn (HORN) |

| R6 | Cooling fan (FAN NO.1) |

| R7 | Engine control unit (EFI-MAIN) |

| R8 | Ignition (IG2) |

| R9 | Dimmer (DIMMER) |

| R10 | Hatchback, Station wagon: Stop lamps (STOP LP) |

| R11 | Headlights (H-LP) |

| R12 | 1NR-FE, 1ZR-FAE, 1ZR-FE, 2ZR-FE: Fuel pump (C/OPN) |

| 1AD-FTV: Engine control unit (EDU) | |

| 1ND-TV, 8NR-FTS: Engine control unit (EFI MAIN NO.2) | |

| R13 | Hatchback, Station wagon (1AD-FTV): Engine control unit (EFI MAIN NO.2) |

| 1ND-TV): (TSS-C HTR) | |

| Sedan (before November 2016): Stop lamps (STOP LP) | |

| Sedan (from November 2016): (TSS-C HTR) | |

| A | |

| R14 | Sedan: Rear window defogger (DEF) |

| R15 | 1ND-TV): (TSS-C HTR) |

| R16 | 1ND-TV): Heated rear window (DEF) |

| R17 | 1ND-TV (from May 2015)): Heated rear window (DEF) |

| B | |

| R14 | Transmission (AMT) |

| 8NR-FTS: Cooling fan (FAN MAIN) | |

| R15 | 1AD-FTV): Cooling fan (FAN NO.2) |

| Sedan: — | |

| R16 | 1AD-FTV): Cooling fan (FAN NO.3) |

| Sedan (1ZR-FE, 1ZR-FAE, 2ZR-FE, 1NR-FE): Heated brush rest area (DEICER) | |

| R17 | 1ND-TV (since May 2015)): — |

Additional items

What most often breaks in a Toyota steering column?

As a rule, the first thing that fails in it is the bushing. This element tends to wear out. Due to this, the column begins to play, and a slight knock appears. Replacing it is not very difficult; below we will tell you and show you how to correctly replace the bushing. The photo below shows the already pulled out bushing.

The second element of the column, which also tends to fail, is the lower cross. We will also talk about the process of replacing it. So, let's proceed directly to replacing these parts. In the photo below you can see the lower cross.

This is interesting: Checking the electrical power windows of Toyota Camry

Replacing the bushing: step-by-step instructions

The process of replacing the bushing is not very complicated. First of all, the car must be driven into the garage, since repairs will take some time. So let's get started. We remove the steering column panel - this is very simple, we need to unscrew all the bolts and remove it from the latches. As a rule, it is held on by three bolts. After this, we remove part of the air vent - which does not interfere with washing - there will be a lot of dust in it.

After our workplace has been prepared, we unscrew everything that prevents us from removing the steering column. When this work has been done, we use a marker to mark the position of the column that we will need to establish during its final collection. So, the column is removed - we do it carefully, since it weighs a lot. In the photo below we will see the place without the column, as well as the column itself and its bushing in an approximate version.

Next, we need to put something soft on the floor, for example, foam rubber and a rag on top of it. Next, on the prepared surface, with the steering wheel down, we place the steering column itself. You won't be able to pull the bushing out by hand. Therefore, we screw several screws into it - they will serve as a support for us to further pull it out. When the self-tapping screws are not fully screwed in, cover the steering wheel with a rag and rest your feet on it, and with your hands, using pliers, pull the sleeve by the self-tapping screws. After some effort, it will come out of its place. In the photo you will see that the bushing is no longer there.

Next, we need to clean the shaft from old grease and dirt. After cleaning, treat it with new lubricant and install the new part in its place.

As a rule, after replacing it, the knocking disappears, but if the crosspiece is in order. If it was broken or worn out, it also needs to be replaced. Now it's time to replace the cross.

Parsing Toyota Corolla 120 body: where Parsing66 gets the parts

In our online store you will not find Chinese or low-quality components at exorbitant prices. If you came for this, then you are in the wrong address, because the disassembly of the Toyota Corolla 120 body offers only original parts with a guarantee, and even for almost nothing!

It's no secret that many cars are sold for spare parts or scrapped. These are the cars we purchase and disassemble into small parts. Quite often we had to disassemble a Toyota Corolla 120 body, so now you can buy used spare parts for a hatchback, sedan or station wagon.

All cars that come for disassembly can be viewed in a special section on the website, and the parts obtained in this way are presented in the Toyota spare parts catalog.

When a car comes to us for analysis, we evaluate what has been preserved. After the assessment, we begin dismantling the components. Parts that could not be repaired are thrown away, and the workers are carefully checked and only after a test drive they are put on the counter.

How to properly change the lower crosspiece of the steering column?

To carry out repairs to this unit, we will also need a garage. First of all, we unscrew the protective cover of the steering column itself, which prevents us from getting to the cross itself. We only need to unscrew three bolts - this is not very difficult to do.

Before unscrewing the steering column, you need to block it - this will allow you to leave the signal cable intact and not torn. Next, as when replacing the bushing, we need to mark the position of the steering wheel.

So, we have it in our hands - the lower cross assembly. You can see in the photo that it is slightly worn.

Next we need to disassemble it. We didn’t bother the part too much - we clamped it in a vice and cut off the crosspiece itself. This must be done very carefully so as not to damage the outer part of the knee.

After the crosspiece was removed in such a rough way, we noticed that there was moisture inside it and there was a complete lack of lubrication - these two points became decisive in the process of destruction of the crosspiece and the appearance of knocking. Stop looking at the old cross - let’s take the seats and begin preparing them for the new part. To do this, we need to thoroughly clean the seats.

When the seats on both sides have been cleaned, we take the cross itself and begin to prepare it. We remove the caps and additionally treat everything with lubricant before pressing. The pressing process is very simple, and the photo below will help you understand it in more detail.

Speaking of the cross itself. It is best to buy an original spare part in stores, with technical specifications that will strictly correspond to your car model. However, there is also a cheaper option; on the Internet, many craftsmen say that the crosspiece from the steering column of a VAZ car is perfect for Toyota. That's what we did - it cost us 160 rubles. It is shown separately in the photo below.

When the crosspiece has been completely pressed in, we need to check everything again and lubricate it with additional grease to prevent moisture from getting inside, which destroys the assembly. Bottom photo is the lower cross assembly.

As we can see, there is nothing complicated in the process of replacing it; all we have to do is put everything back in its place. It won't be difficult to do this. Having put everything together, we can check our car - as you will notice, the steering wheel is like new - no knocks or play. This completes the procedure for replacing the crosspiece, enjoy your use.

How to buy used spare parts for Toyota Corolla 120 hatchback, sedan and station wagon?

In fact, you could go to the market or a specialized store and select the appropriate component there. But then there is a risk of buying an expensive, but not quite high-quality part. What to do? Order spare parts for Toyota Corolla 120 sedan on the website Razbor66. How to do this?

- You can call the hotline, but it’s better to go to the website.

- Select the make and model of car you are interested in.

- Decide on a category.

- Select the required part, carefully look at the completeness and condition.

- Checkout.

- Wait a little.

- Receive the component and check it.

Faulty spare parts or parts that for some reason did not suit you (although this happens extremely rarely) can be exchanged or issued a refund. The main thing is that the warranty periods are respected.

What are you waiting for? It's time to roll up spare parts for the Toyota Corolla 120 and revive your iron horse!

Removing the steering column assembly

Rice. 5.25. Connectors and clamps for fastening wiring harnesses of the steering column assembly

Disconnect the connectors and clamps securing the wiring harnesses from the steering column assembly (Fig. 5.25).

Loosen bolt A.

Loosen the three bolts B securing the steering column.

Mark the relative position of the steering shaft spline clamp and the steering intermediate shaft.

Remove the bolt and disconnect the splined clamp and intermediate steering shaft.

Remove the three bolts and remove the steering column assembly.

Removing the steering shaft spline clamp

Rice. 5.26. Marks of the relative position of the steering shaft splined clamp and the intermediate steering shaft No. 2

Note the relative position of the steering shaft splined clamp and the intermediate steering shaft No. 2 (Fig. 5.26).

Unscrew the bolt and remove the steering shaft splined clamp.

Removing the intermediate shaft No. 2 of the steering control

Rice. 5.27. Marks of the relative position of the intermediate shaft No. 2 and the main steering shaft

Note the relative position of the intermediate shaft No. 2 and the main steering shaft (Fig. 5.27).

Unscrew the bolt and remove the intermediate shaft No. 2 of the steering.