How to change the rear hub of a Toyota Corolla

To replace, you will need to dismantle the wheel, remove the brake caliper, pads and brake disc. Next, how to replace the rear suspension hub of a Toyota Corolla E150 will be explained in the following instructions:

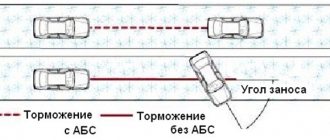

Wear or damage to the wheel bearing leads to unstable behavior of the car when cornering and while driving, which negatively affects the safety of the Toyota Corolla 150. Therefore, if symptoms of a hub malfunction occur, it is necessary to immediately diagnose its condition and, if necessary, replace it.

The design of the front hub does not allow the bearing to be replaced separately. For this reason, it is necessary to purchase an assembled unit. The original front hub has part number 43550-42010. The price of the unit is 13-18 thousand rubles.

Car owners have the opportunity to purchase a hub from a car wrecker. A spare part with accompanying documents will cost 3-9 thousand rubles. When purchasing a hub from a domestic dismantling site, the remaining resource, in most cases, is unknown. The cost of such a part ranges from 1 to 5 thousand rubles.

Not wanting to purchase used components, car owners recommend taking a closer look at good analogues from third-party manufacturers, for example, the Aisin company. A list of other best options from hub manufacturers is shown in the table below.

Article number of original hubs with approximate cost of the part

The following parts are installed on vehicles from the factory:

- front - Toyota 43550-42010 (cost 7-13 thousand rubles);

- rear - Toyota 42450-02060 (price in spring 2021 is 6.5-8.1 thousand rubles).

The parts are supplied to the Toyota assembly line by Koyo. The manufacturer's markings are present on the surface of the components. For example, a product with article number 3DACF041D3 (price starts from 11.7 thousand rubles) can be used on the front. It is possible to install an element with the number 3DACF026F7AS at the rear (costing from 5.3 thousand rubles). When choosing spare parts, you must use catalogs and take into account the vehicle's VIN number.

Will the hub from Toyota Auris fit?

Toyota Auris and Corolla cars, built on the same E150 platform, have the same chassis. For right-hand drive cars intended for the Japanese domestic market, parts with original numbers were installed. According to the owners' reviews, the landing dimensions of the hubs for cars with left and right-hand driver's seats and the characteristics of the built-in ABS sensor do not differ; modification of the wiring plug is not required.

Article number and price of branded rear wheel bearings for Toyota Corolla 150 and their analogues

Replacing the rear wheel bearing also requires purchasing a complete hub, since the unit is non-separable. Any attempts to press in a new bearing lead to its rapid failure and can also cause malfunctions of the ABS system. The original rear hub has part number 42450-12090. Its price is 13-19 thousand rubles.

Spare parts are available for sale from car dismantling yards. Since the Toyota Corolla 150 rear hub is not a reliable unit, finding a good used part is quite problematic. The cost of supported hubs starts from 1600 rubles. Their residual life is extremely low and the bearing can hum after a couple of thousand km.

In addition to branded products, analogues from third-party manufacturers can be used to replace the rear hub. Recommended brands, the quality and performance characteristics of which are not inferior to the original, are shown in the table below.

Table - The best alternatives to the original rear hub of the Corolla 150

| Company manufacturer | Article number | Approximate cost, thousand rubles |

| SAT | ST4245012090 | 2-3 |

| Nipparts N4712080 3-5 | N4712080 | 3-5 |

| Koyo | 3DACF027F11FS | 5-71 |

| Masuma | MW11508 | 4-8 |

| Blue Print | ADT38390 | 2.5-5.5 |

How to determine the need to replace a bearing in a TOYOTA

I personally do it this way, and I advise you to.

1.After driving the car for a long time, gently place your palm on the hub. If it is hot, then this is the first sign of bearing failure.

2. Get behind the wheel of a car, pick up speed up to 40 km/h, open all the windows and listen carefully. If, in addition to the noise of the wheels on the road, you hear a grinding, whistling, or howling noise, then this also indicates a problem with the part.

3.Gain high speed. The sound intensifies and periodically disappears, and then appears with renewed vigor - indicates a problem in the hub.

4.When driving, vibration appears in the cabin. Especially in the back.

Just in case, jack up the car and spin the wheel by hand. You will hear a characteristic cracking sound.

This means that the part absolutely needs to be replaced.

You have decided that there is a breakdown and needs repair.

And you want to do the repairs yourself.

In order to do all this, you need to prepare before starting the repair.

Symptoms of wheel bearing failure

Symptoms of a wheel bearing failure are:

- hum and other extraneous sounds from the wheel;

- uneven tire wear;

- vibration that is transmitted to the steering wheel and body;

- reduction of free run;

- backlash, which can occur both cold and hot;

- wheel jam;

- heating of the hub after movement;

- the need for constant steering, as the car pulls to the side;

- increased fuel consumption;

- decrease in the dynamics of the Corolla 150.

Practice tips

They are as follows:

— not every garage has a press. Use a service station to remove the bearing and press it into place. It's not expensive, but it will speed up the repair process. Perform the rest of the operations in your garage;

- if you have already dismantled the unit, look around it. Perhaps you will visually see parts that require repair at the same time;

- do not reuse the old retaining ring;

- If possible, replace the bearing on the other side at the same time. Since its service life has also come to an end, although it does not buzz;

— to protect yourself when purchasing a bearing, ask to see the certificate and dealer agreement at the car store;

— after replacing the part, check the wheel camber and toe.

If you have any questions during the work process, please contact me in the comments, I will always be happy to help with practical advice.

Required Tools for Wheel Bearing Replacement

To replace wheel bearings, you need the tools from the table below.

Table - List of required tools

| Name | Note |

| Screwdriver | With a flat, durable blade |

| Hub nut wrench | With extension |

| Mount | Several pieces of different thickness |

| Hammer | With a larger than average head or a sledgehammer |

| Balloon wrench | To remove the wheel |

| Key | "at 10", "at 14", "at 17" |

| Penetrating lubricant | For example, WD-40 |

| Wheel chocks | 2 pcs |

Also, during the replacement process, you will need a piece of strong wire and a rag to clean up dirt.

Preparing for DIY repairs

I advise you to do this - select tools and accessories.

Complete the following items:

- jack;

- hammer;

- a set of main keys and sockets. Please note that there is a head No. 30;

- chisel, pliers, wide screwdriver;

- vice;

- If possible, a torque wrench.

It doesn't matter if you don't have a torque wrench.

I advise you how I do it.

When tightening bolts and nuts with a regular wrench, tighten them firmly until they stop and then release them, turning the wrench 20 degrees in the opposite direction.

And you don't need a torque wrench.

Next, prepare:

- metal mandrel;

- wooden block

- a small sheet of thick rubber;

— penetrating liquid VD40 (Vedeshka).

It is advisable, but not at all necessary, to view a schematic sketch or drawing of the hub.

The process of replacing the front wheel bearing on a Toyota Corolla 150

The front wheel bearing is replaced together with the hub. Detailed instructions are given below.

- Jack up the car.

- Remove the wheel.

- Release the hub nut stopper.

- Unscrew the hub nut.

- Unscrew the two caliper mounting bolts.

- Remove the bracket.

- Remove the brake disc.

- To make it easier to dismantle the hub, treat its fastenings with penetrating lubricant.

- Unscrew the hub fastenings.

- The hub gets stuck very often. It must be torn out of place using a sledgehammer or large hammer. You need to hit the inside of the hub. When a gap appears, you need to insert a pry bar into it and jerk the hub out.

- Install the new hub and reassemble everything in the reverse order of removal.

Practical recommendations

When servicing the front suspension, the removed brake disc can be used to remove the hub. The part is put on the studs, onto which the fastening nuts are then screwed 2-3 turns. The repairman sequentially pulls the disk towards himself and turns the hub, ensuring uniform distribution of force. After 10-15 jerks, the parts are separated, but if there is corrosion on the surface, then the muscular strength of a person is not enough to remove the assembly.

To remove the hub in the front suspension, a bolt with an increased length can be used, which is alternately screwed into the standard holes. Then the head of the bolt is struck through the metal spacer with a hammer. After a gap appears between the fist and the hub, a mounting blade is inserted into the gap, allowing the parts to be separated. The design of the steering knuckle includes a metal protective shield for the brake mechanism. When reassembling, take into account the position of the element; tighten the bolts crosswise.

During assembly, the tightening torques of threaded connections should be monitored:

- wheel nuts are tightened with a force of 103 N*m;

- the axle shaft shank nut requires a load within 292 N*m.

When reassembling, it is recommended to treat the mating surfaces with a special lubricant that is resistant to water and high temperatures. When servicing, it is necessary to check the remaining thickness of the brake discs and the condition of the pistons and seals in the calipers. Parts with excessive wear should be replaced, since the safety of the vehicle depends on the condition of the brake system.